Polyethylene composite for drip irrigation pipes

A composition and polyethylene technology, applied in the fields of application, botanical equipment and methods, climate change adaptation, etc., can solve the problems of scratches or even abrasions, poor puncture resistance, etc., and achieve excellent wear resistance and puncture resistance The effect of good performance and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

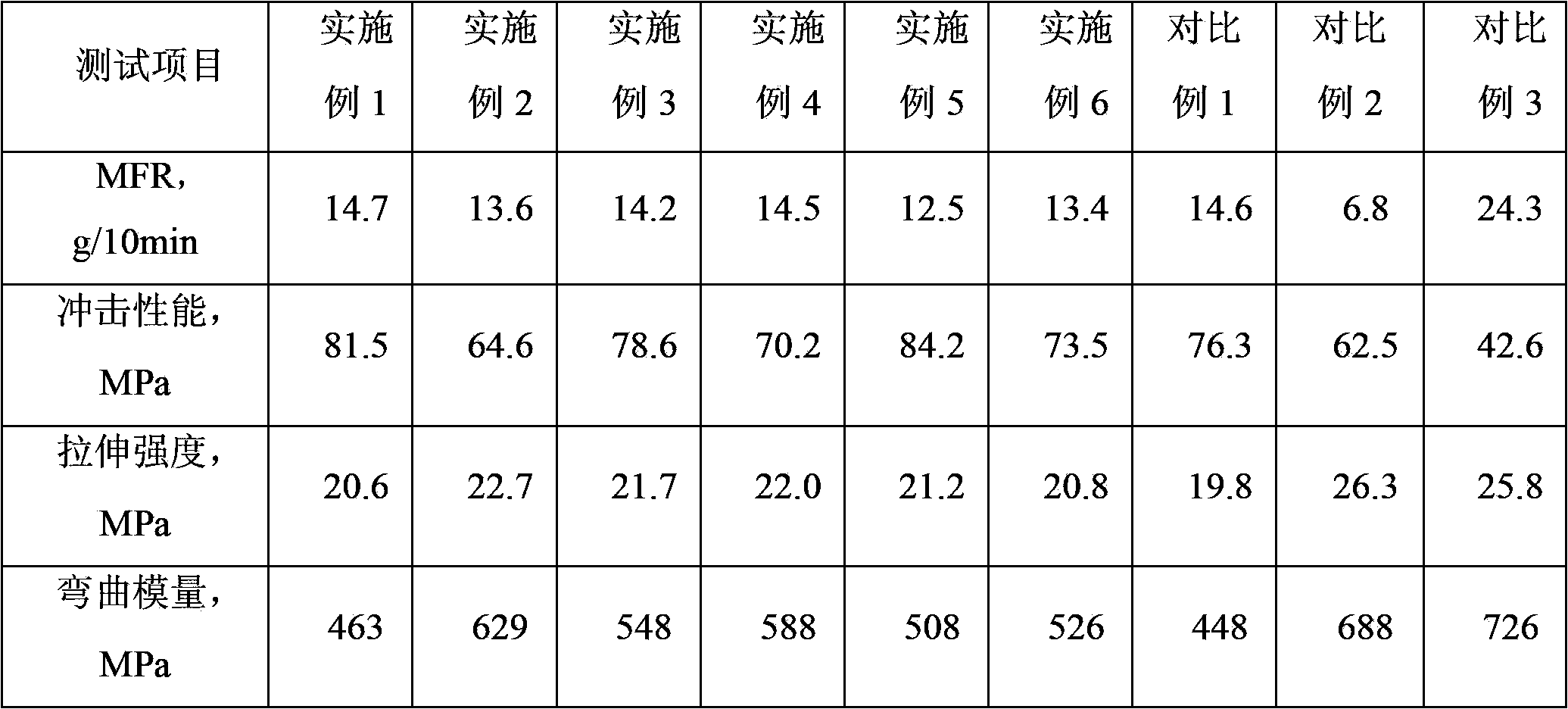

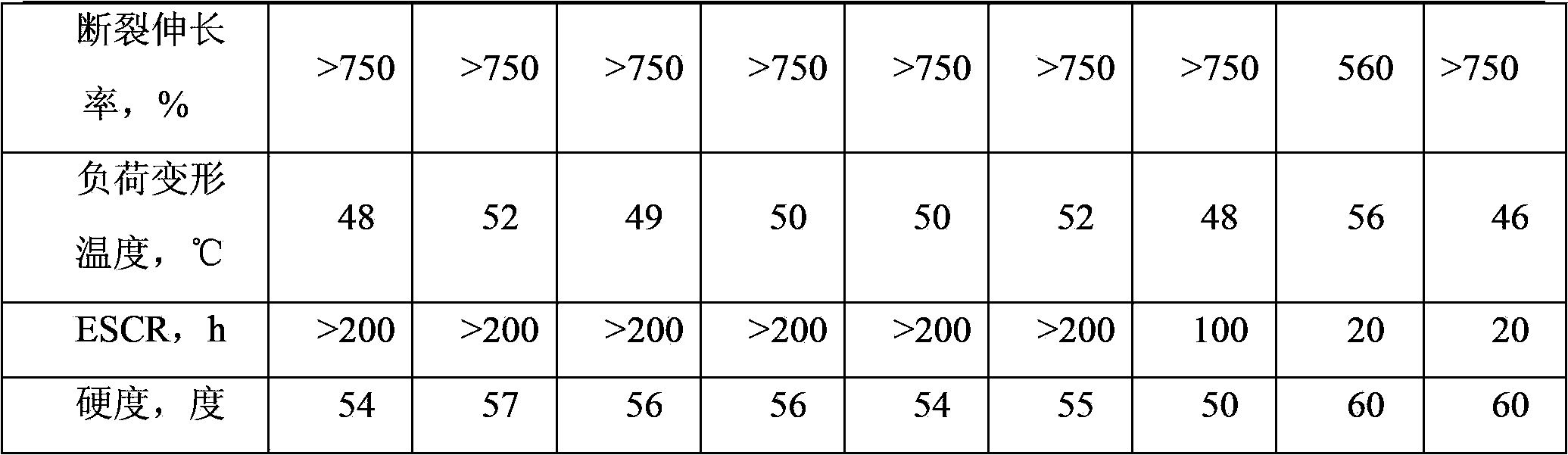

Examples

Embodiment 1

[0029] High-density polyethylene resin, 50 parts (density 0.945g / cm 3 , The melt mass flow rate is 12g / 10min, the weight average molecular weight is 260,000, the molecular weight distribution width index is 22, ESCR>1000h, produced by chromium catalyst).

[0030] High pressure polyethylene resin, 25 parts (density 0.919g / cm 3 , The melt mass flow rate is 2.0g / 10min).

[0031] Metallocene polyethylene resin, 25 parts (density 0.920g / cm 3 , The melt mass flow rate is 1.0g / 10min, the molecular weight distribution breadth index is 3.08, the weight average molecular weight is 123,500, and the comonomer mole percentage is 2.53%).

[0032] Carbon black masterbatch, 4 parts (masterbatch concentration 50%).

[0033] Antioxidant, 0.2 part of tris[2.4-di-tert-butylphenyl] phosphite, [β-(3,5-di-tert-butyl 4-hydroxy-phenyl) propionate] pentaerythritol ester, 0.15 part.

Embodiment 2

[0035] High-density polyethylene resin, 40 parts (density 0.945g / cm 3 , The melt mass flow rate is 12g / 10min, the weight average molecular weight is 260,000, the molecular weight distribution width index is 22, ESCR>1000h is produced by chromium-based catalyst).

[0036] High pressure polyethylene resin, 20 parts (density 0.915g / cm 3 , The melt mass flow rate is 2.5g / 10min).

[0037] Metallocene polyethylene resin, 20 parts (QHM22F metallocene polyethylene produced by Qilu Petrochemical Company, density 0.937g / cm 3 , The melt mass flow rate is 0.6g / 10min, the molecular weight distribution breadth index is 3.46, the weight average molecular weight is 146,000, and the molar percentage of comonomer is 0.59%).

[0038] Carbon black masterbatch, 5 parts (masterbatch concentration 40%).

[0039]Antioxidant, tris[2.4-di-tert-butylphenyl] phosphite 0.15 parts, β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, 0.15 parts, [β - Pentaerythritol (3,5-di-tert-butyl-4-hydroxy-...

Embodiment 3

[0041] High-density polyethylene resin, 50 parts (density 0.940 g / cm 3 , The melt mass flow rate is 14g / 10min, the weight average molecular weight is 180,000, the molecular weight distribution width index is 20, ESCR>1000h, produced by chromium catalyst).

[0042] High pressure polyethylene resin, 25 parts (density 0.925g / cm 3 , The melt mass flow rate is 1.5g / 10min).

[0043] Metallocene polyethylene resin, 20 parts (density 0.915g / cm 3 , Melt mass flow rate 2.0g / 10min, molecular weight distribution breadth index 2, weight average molecular weight 100,000, comonomer mole percentage 0.5%).

[0044] Carbon black masterbatch, 4 parts (masterbatch concentration 30%).

[0045] Antioxidant, 0.15 part of tris[2.4-di-tert-butylphenyl] phosphite, [β-(3,5-di-tert-butyl 4-hydroxy-phenyl) propionate] pentaerythritol ester, 0.1% part.

[0046] Fluoroelastomer, 0.3 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com