Front connector of high air-pressure down-the-hole hammer

A technology for down-the-hole impactors and front joints, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. The effect of cost input, service life improvement and use cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

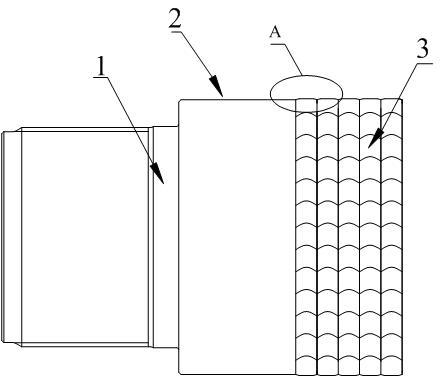

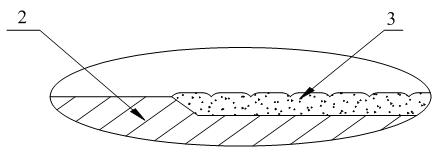

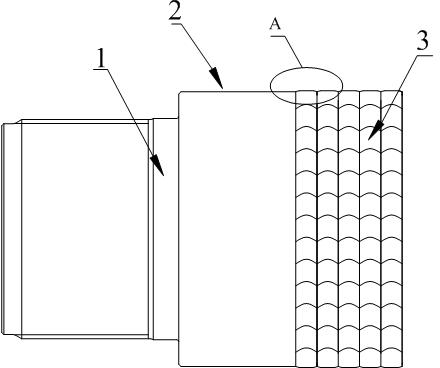

[0014] like figure 1 As shown, in the front joint of the high wind pressure down-the-hole impactor, the outer circle 2 with the largest front end diameter of the front joint 1 is welded with a wear-resistant material layer 3, and the welding seam direction of the wear-resistant material layer 3 is along the axial direction of the front joint, or The wear-resistant material layer 3 is a tungsten carbide wear-resistant electrode along the circumferential direction of the front joint or at an inclination angle with the axial direction of the front joint.

[0015] like figure 2 As shown, there is a welding groove on the outer circle 2 with the largest diameter at the front end of the front joint, and a certain thickness of wear-resistant material layer 3 is welded on the welding groove. For the welding groove of the surfacing wear-resistant material layer, the length of the welding groove accounts for about 1 / 2 of the length of the large outer circle. The outer circle after wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com