Filter disc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

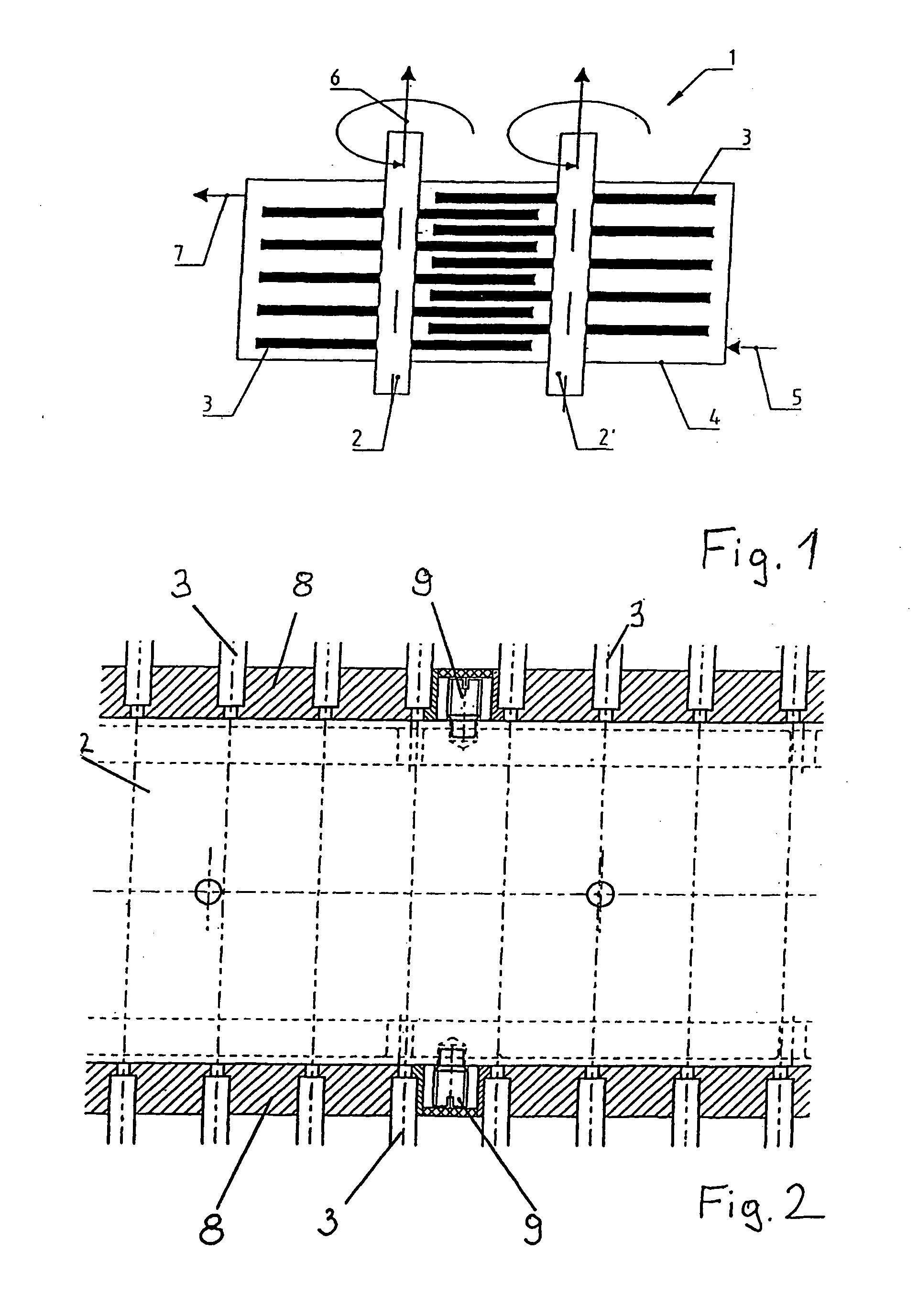

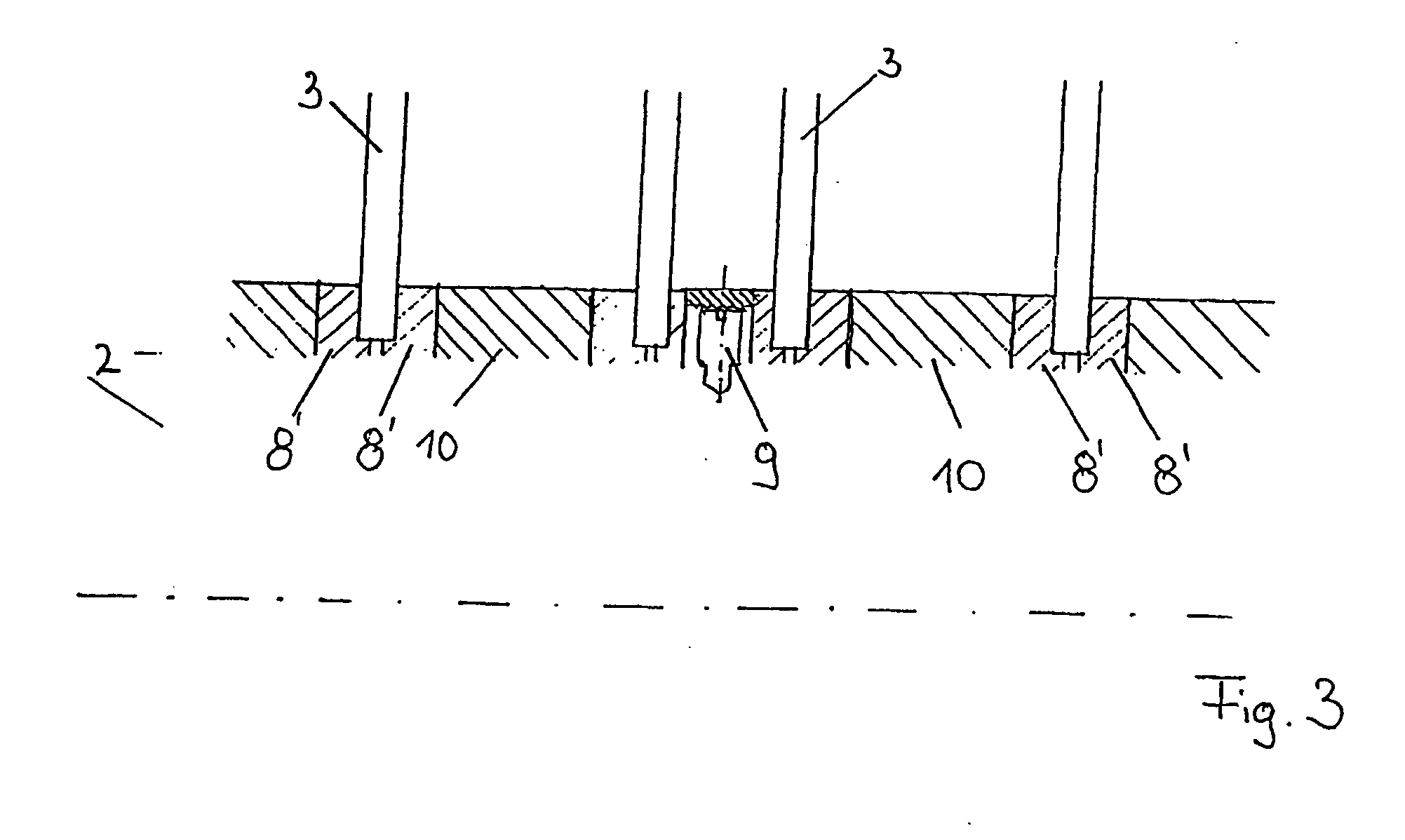

[0036]FIG. 1 shows a state of the art filtration module 1. Several membrane discs 3 are secured to each of the centre cores 2, 2′. The liquid / suspension to be filtered is fed into a tank 4 through a pipe 5. A closed tank 4 is shown here. The tank can also be open, in which case the membranes are submerged into the liquid. The membrane discs 3 have a cylindrical cross-section here. The filtrate passes through the membrane into the hollow disc body 3 and is guided to the centre of the disc as permeate and then through the centre core 2, 2′ and through a pipe 6 out of the filter. The cleaned concentrate can be drained off later through a pipe 7. The membrane module 1 can be operated both with overpressure on the concentrate side and with underpressure on the permeate side. Correspondingly, the module 1 can be used as a closed casing or as submerged membranes. The overpressure can be as high as 10 to 14 bar.

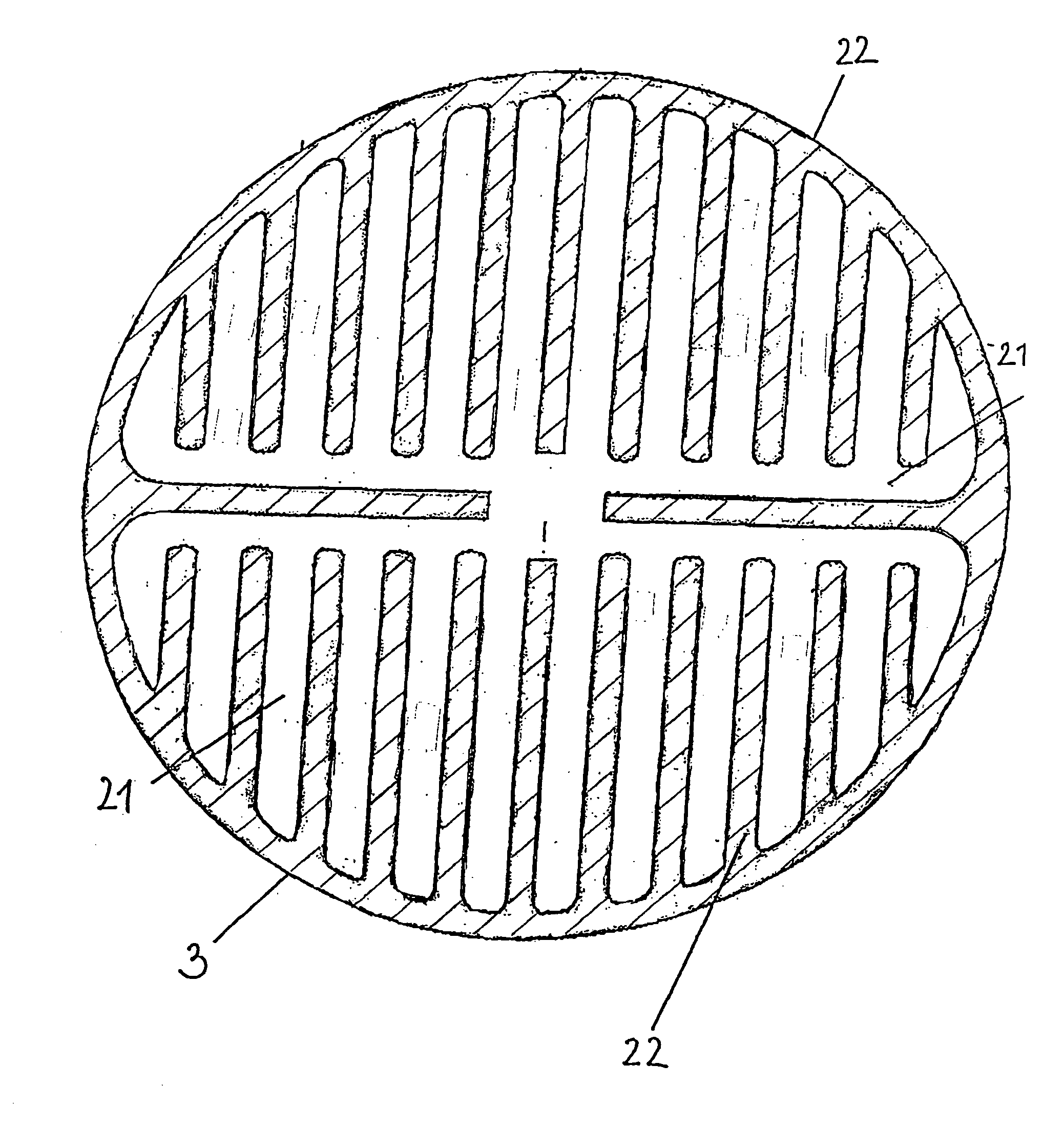

[0037] The membrane discs 3 may comprise inorganic elements, as well as support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com