A nanometer multi-layer AlTiN/MoVCuN coating and a preparing method and applications thereof

A nano-multi-layer and coating technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of easy volatilization, lower high temperature wear resistance, lower high temperature wear resistance, etc., and achieve surface Smooth, structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

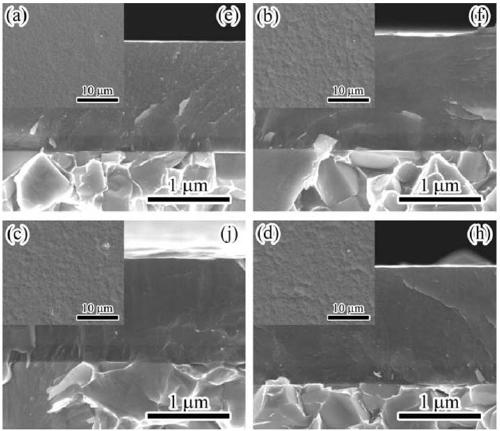

[0030] A nano-multilayer AlTiN / MoVCuN coating, which includes a substrate base, a Cr bombardment implant layer, a CrN transition layer, and a nano-multilayer AlTiN / MoVCuN coating from bottom to top; a nano-multilayer AlTiN / MoVCuN coating It is formed by alternate deposition of AlTiN intermediate layer and MoVCuN intermediate layer with a modulation ratio of 3:2, and the modulation period is 0.6-2.4nm; the atomic percentage content of each element in the nano-multilayer AlTiN / MoVCuN coating is: Al 10.6at. %, Ti 7.0at.%, Mo 28.8at.%, V5.8at.%, Cu 1.4at.%, N 46.4at.%.

[0031] The preparation method follows the steps below:

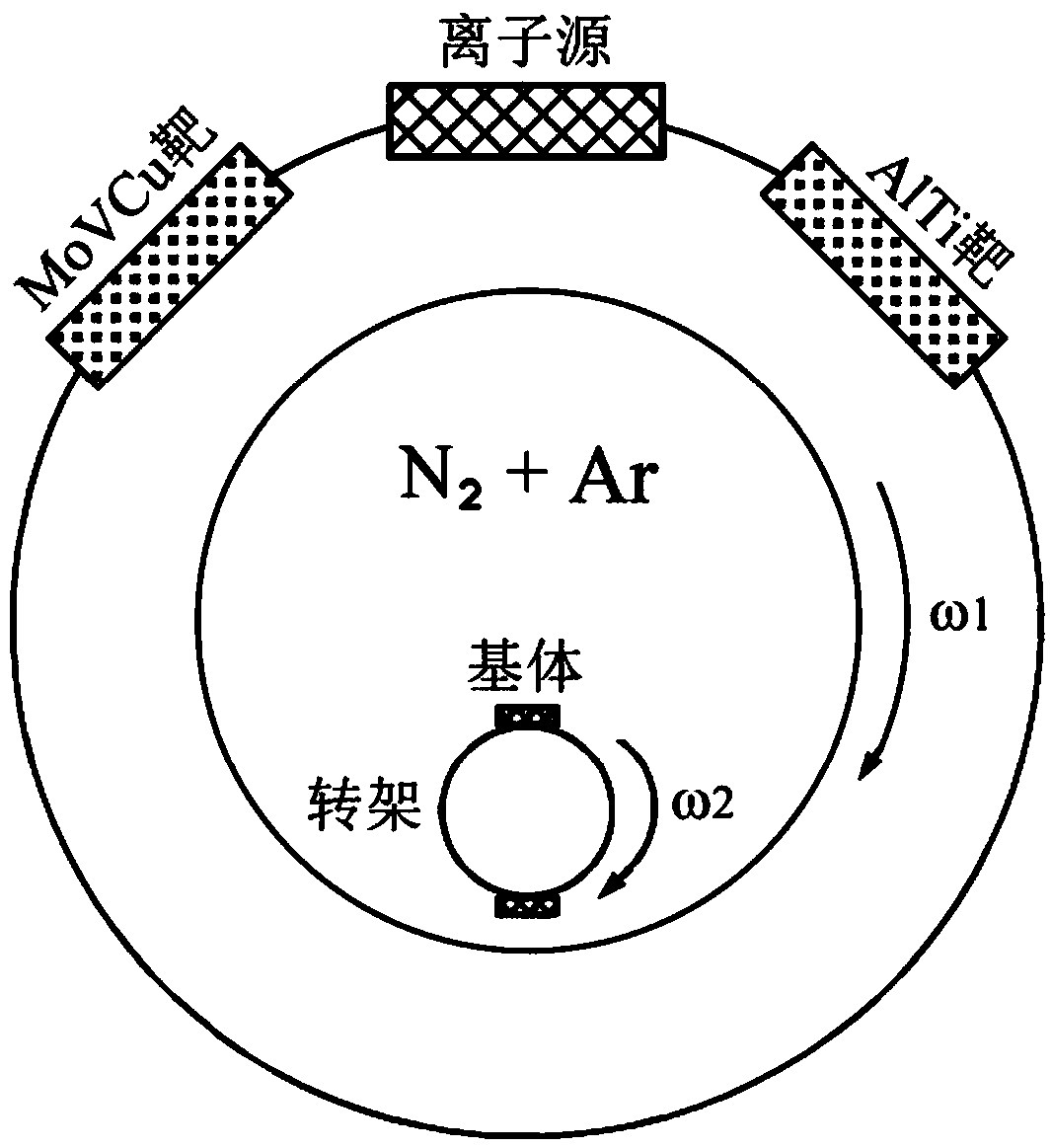

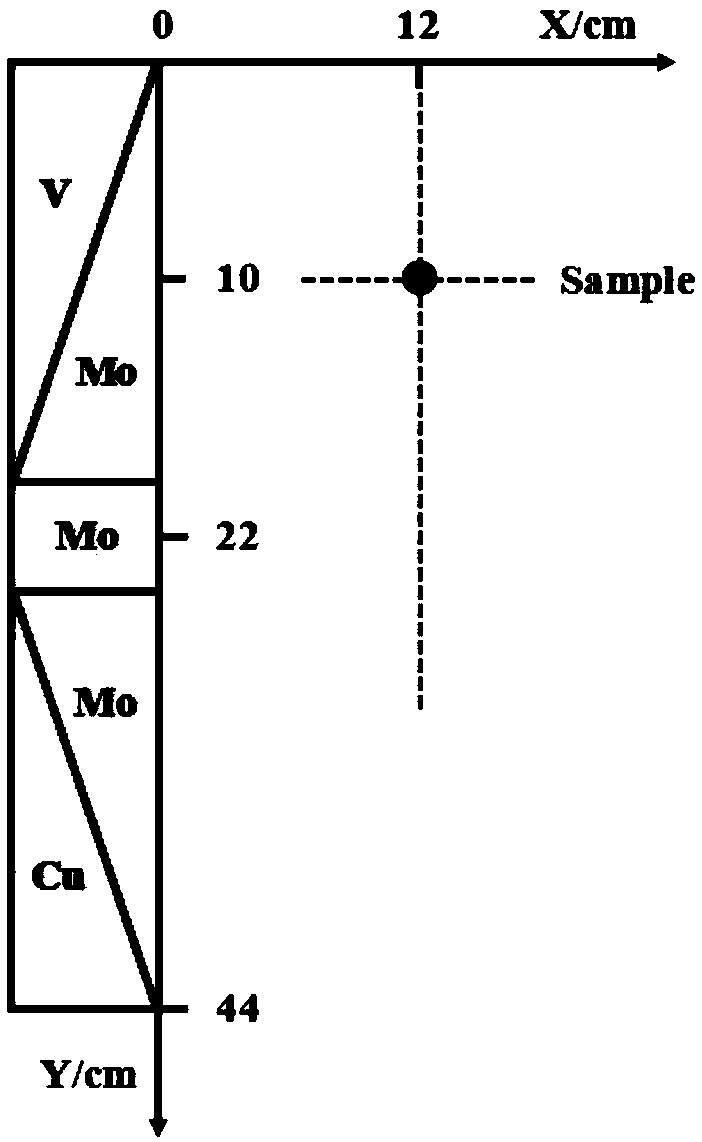

[0032] (1) Fix the pretreated substrate base on the workpiece turret in the coating chamber, so that the base is facing the target surface, the distance between the target and the base is 120cm, adjust the rotation speed of the turret to 3rpm, and the revolution speed to 1rpm, and turn on the heater Raise the temperature to 200°C, pre-pump the background va...

Embodiment 2

[0040] A nano-multilayer AlTiN / MoVCuN coating, which includes a substrate base, a Cr bombardment implant layer, a CrN transition layer, and a nano-multilayer AlTiN / MoVCuN coating from bottom to top; a nano-multilayer AlTiN / MoVCuN coating It is formed by alternate deposition of AlTiN interlayer and MoVCuN interlayer with a modulation ratio of 3:2, and the modulation period is 0.6-2.4nm; the atomic percentage content of each element in the nano-multilayer AlTiN / MoVCuN coating is: Al 10.9at. %, Ti 6.7at.%, Mo 29.2at.%, V5.6at.%, Cu 1.0at.%, N 46.6at.%.

[0041] The preparation method follows the steps below:

[0042] (1) Fix the pretreated substrate base on the workpiece turret in the coating chamber so that the base is facing the target surface, the distance between the target and the base is 120cm, adjust the rotation speed of the turret to 3rpm, and the revolution speed to 2rpm, and turn on the heater Raise the temperature to 200°C, pre-pump the background vacuum to 5.0×10 -...

Embodiment 3

[0050] A nano-multilayer AlTiN / MoVCuN coating, which includes a substrate base, a Cr bombardment implant layer, a CrN transition layer, and a nano-multilayer AlTiN / MoVCuN coating from bottom to top; a nano-multilayer AlTiN / MoVCuN coating It is formed by alternate deposition of AlTiN interlayer and MoVCuN interlayer with a modulation ratio of 3:2, and the modulation period is 0.6-2.4nm; the atomic percentage content of each element in the nano-multilayer AlTiN / MoVCuN coating is: Al 11.4at. %, Ti 6.7at.%, Mo 27.3at.%, V5.8at.%, Cu 0.4at.%, N 48.4at.%.

[0051] The preparation method follows the steps below:

[0052] (1) Fix the pretreated substrate base on the workpiece turret in the coating chamber, so that the base is facing the target surface, the distance between the target and the base is 120cm, adjust the rotation speed of the turret to 3rpm, and the revolution speed to 3rpm, and turn on the heater Raise the temperature to 200°C, pre-pump the background vacuum to 5.0×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com