Nanometer multilayer coating and preparation method thereof

A nano-multilayer, coating technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problem of undiscovered coating and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

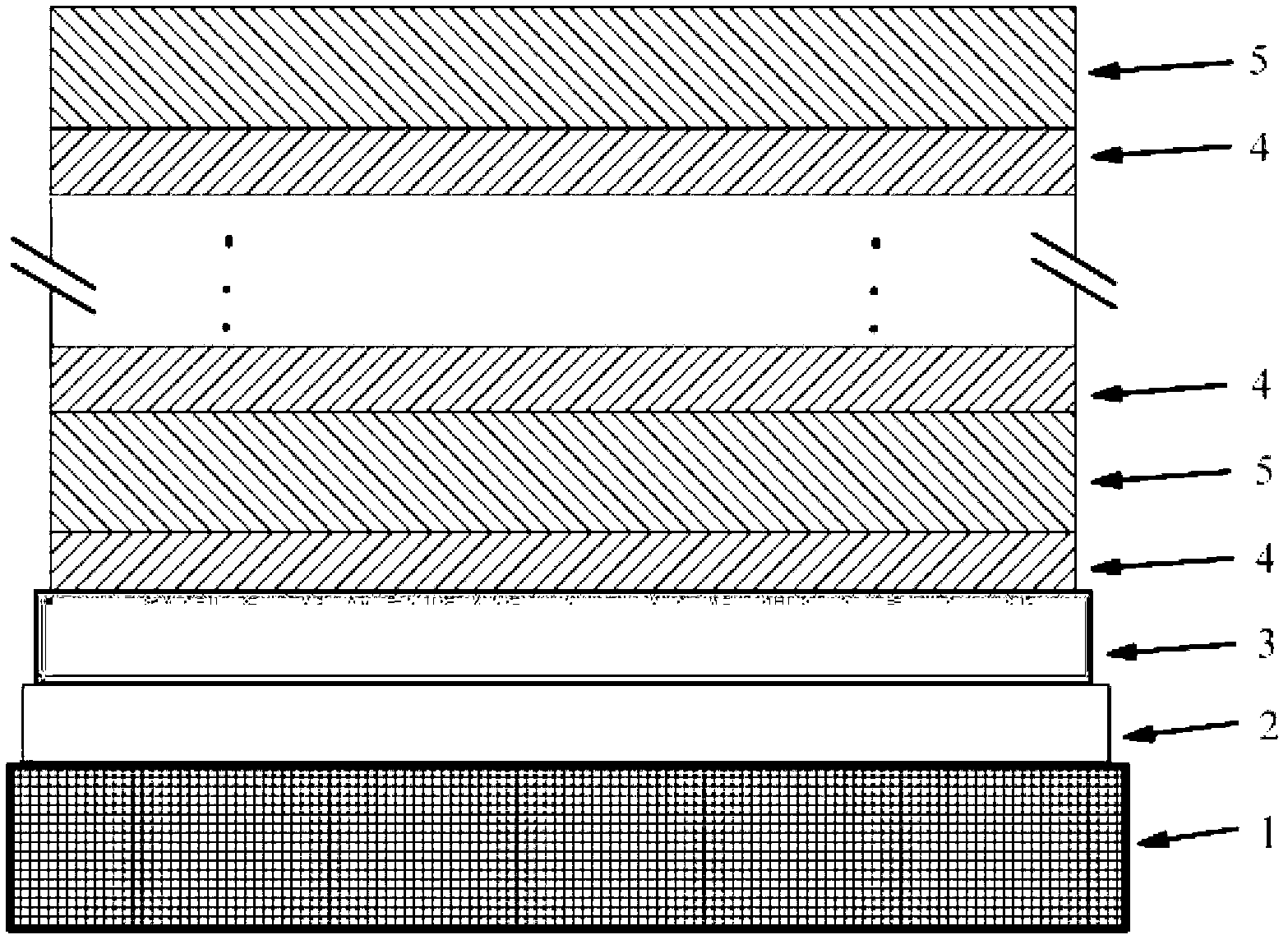

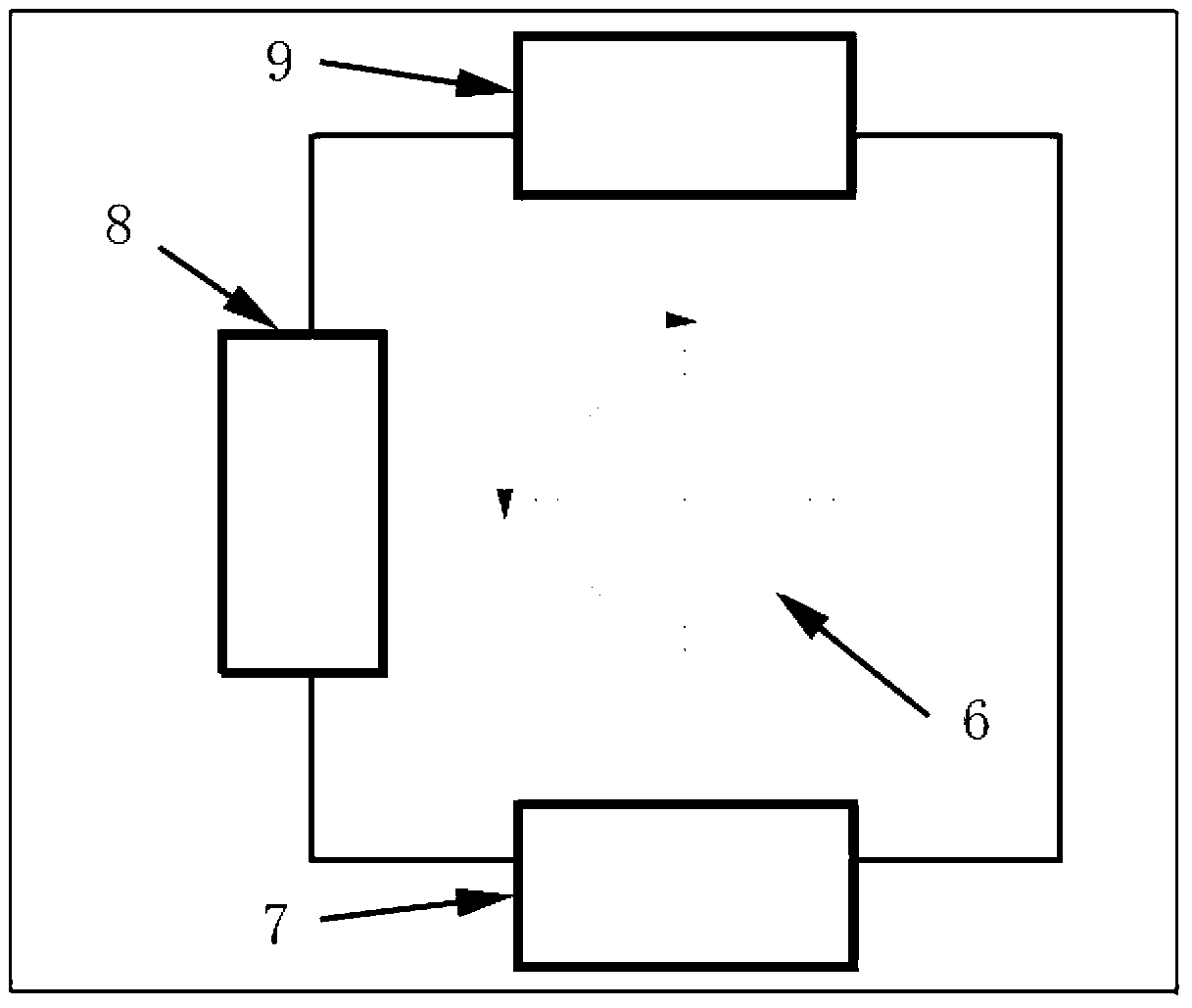

[0040] Example 1: Combining Figure 1 to Figure 4 As shown, the CrAl target and TiAlSi target are prepared by powder metallurgy method, and the Si atom content of the TiAlSi target is 4%; the coating preparation method includes the following steps: Step 1, put the metal or alloy substrate into the cavity of the coating equipment and then vacuumize to 2×10 –3Pa, then turn on the heating power supply to heat the metal or alloy substrate to 350°C and stabilize it, then pass Ar (argon gas) into the vacuum chamber of the coating equipment to maintain a vacuum pressure of 0.2Pa; step 2, set the sample stage to 5 revolutions Start rotating at a speed of 1 / min, and turn on the base negative bias voltage to 500V, then turn on the Cr target ignition power supply at 0.03A / dm 2 The current density of sputtering for 30min; then within 5min, the negative bias voltage was reduced to 75V, and at the same time, the Cr target current density was increased to 2A / dm within 5min 2 , keep 15min; ...

Embodiment 2

[0043] Example 2: Combining Figure 5 ~ Figure 8 As shown, the CrAl target and the TiAlSi target are prepared by powder metallurgy, and the Si atom content of the TiAlSi target is 10%; the coating preparation method includes the following steps: Step 1, put the metal or alloy substrate into the cavity of the coating equipment and then vacuumize to 2×10 –3 Pa, then turn on the heating power supply to heat the metal or alloy substrate to 350°C and stabilize it, then pass Ar (argon gas) into the vacuum chamber of the coating equipment to maintain a vacuum pressure of 0.2Pa; step 2, set the sample stage to 5 revolutions Start rotating at a speed of 1 / min, and turn on the base negative bias voltage to 500V, then turn on the Cr target ignition power supply at 0.03A / dm 2 The current density of sputtering for 30min; then within 5min, the negative bias voltage was reduced to 75V, and at the same time, the Cr target current density was increased to 2A / dm within 5min 2 , keep 20min; st...

Embodiment 3

[0045] Example 3: Binding Figure 9 and Figure 10 As shown, the CrAl target and TiAlSi target are prepared by powder metallurgy method, and the Si atom content of the TiAlSi target is 16%; the coating preparation method includes the following steps: Step 1, put the metal or alloy substrate into the cavity of the coating equipment and then vacuumize to 2×10 –3 Pa, then turn on the heating power supply to heat the metal or alloy substrate to 350°C and stabilize it, then pass Ar (argon gas) into the vacuum chamber of the coating equipment to maintain a vacuum pressure of 0.2Pa; step 2, set the sample stage to 2 revolutions Start rotating at a speed of 1 / min, and turn on the base negative bias voltage to 500V, then turn on the Cr target ignition power supply at 0.03A / dm 2 The current density of sputtering for 30min; then within 5min, the negative bias voltage was reduced to 75V, and at the same time, the Cr target current density was increased to 2A / dm within 5min 2 , keep 20m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com