Nano chlorobutadiene rubber adhesive and preparation method thereof0}

An adhesive, neoprene technology, applied in the direction of chloroprene adhesives, adhesives, adhesive types, etc., can solve the problems of poor storage stability, low production efficiency, and high energy consumption of neoprene adhesives, and achieve peel strength. High, improve production efficiency, good brushability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

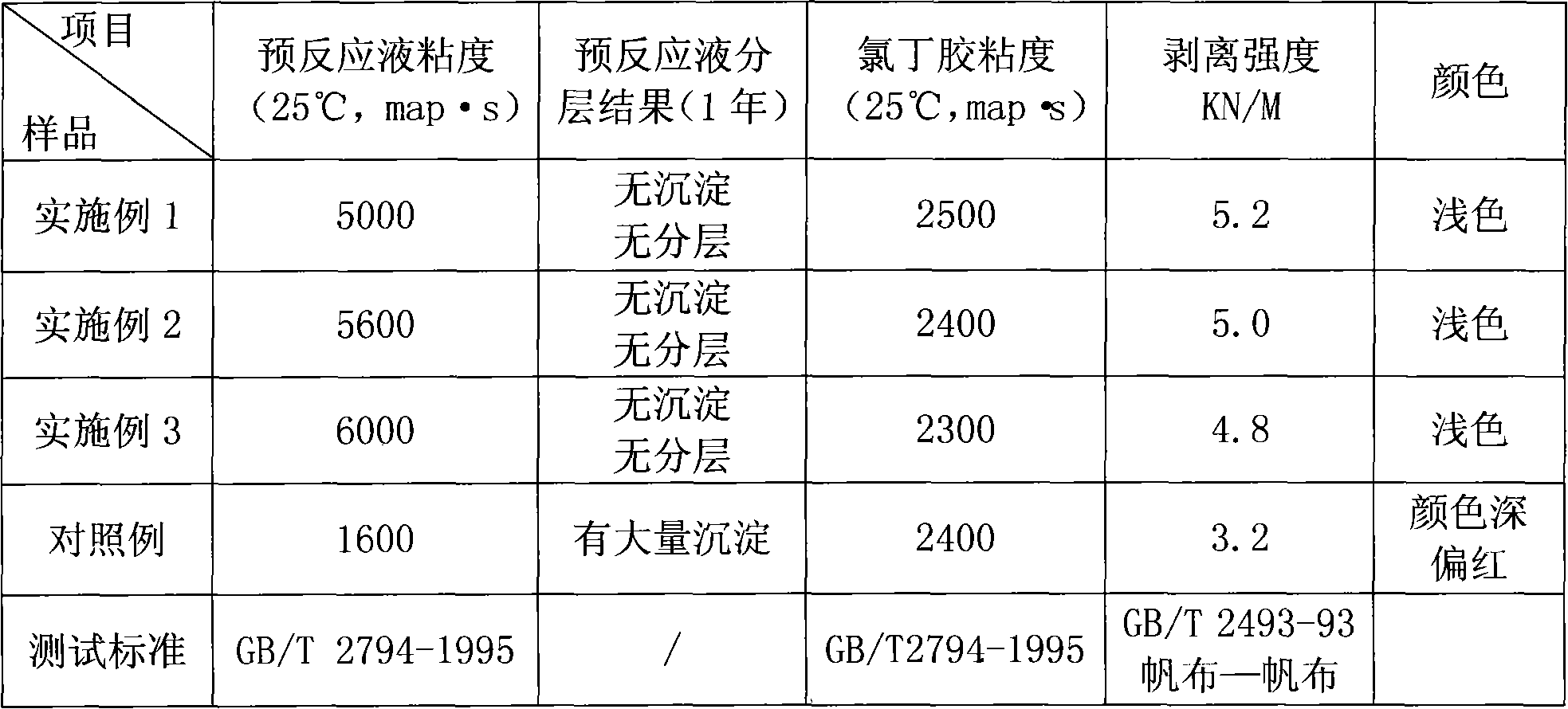

Examples

Embodiment 1

[0034] A. Preparation of pre-reaction solution

[0035] Put 10 parts of toluene and 7.5 parts of cyclohexane into a high-speed disperser, start stirring, set the speed at 100 rpm, add 9 parts of phenolic resin, dissolve for 2 hours, increase the speed to 3000 rpm, and slowly Add 2 parts of nano-magnesium oxide and 0.5 part of catalyst, stir for 50 minutes, reduce the rotation speed to 100 rpm, control the temperature at 20°C to 30°C, and discharge after 8 hours of reaction.

[0036] B. Preparation of nano-chloroprene:

[0037] With 26 parts of toluene, 25 parts of ethyl acetate, 120 # Put 14 parts of solvent gasoline into the double-machine dissolving kettle, start stirring at a speed of 60-80 rpm, add 14 parts of 2442 film, turn on the high-speed disperser, adjust the speed to 1300 rpm, disperse and dissolve the 2442 film, and control the temperature of the material 40°C, disperse operation for 8 hours. Add the pre-reaction liquid into the dual-machine dissolving tank, mix...

Embodiment 2

[0039] The raw materials used in the pre-reaction liquid components are 11 parts of toluene, 6.5 parts of cyclohexane, 12 parts of phenolic resin, 1.5 parts of nano-magnesium oxide, and 0.75 parts of catalyst.

[0040] The raw material used for nano-chloroprene adhesive is 25 parts of ethyl acetate, 22 parts of toluene, 120 # 16 parts of solvent gasoline, 22 parts of 2442 film.

[0041] Manufacturing process is the same as embodiment 1

Embodiment 3

[0043] The raw materials used in the pre-reaction liquid components are 12 parts of toluene, 5.5 parts of cyclohexane, 15 parts of phenolic resin, 2.5 parts of nano-magnesium oxide, and 0.75 parts of catalyst

[0044] The raw materials used for the nano-chloroprene adhesive are 22 parts of ethyl acetate and 25 parts of toluene.

[0045] 120 # 18 parts of solvent gasoline, 18 parts of 2442 film.

[0046] Manufacturing process is the same as embodiment 1

[0047] Reference example

[0048] A, the nano magnesia of the raw material used in the pre-reaction solution is replaced by light magnesia. All the other formulas and technology are with embodiment 1

[0049] B. Neoprene preparation

[0050] Raw material is the same as embodiment 1

[0051] Craftsmanship:

[0052] The 2442 film was masticated 20 times with a rubber mixer

[0053] Add the solvent into the dissolution kettle, start stirring at a speed of 60-80 rpm, add the 2442 film that has been masticated 20 times, con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com