Hydrogenation catalyst using cellular titanium dioxide as carrier and preparation method thereof

A hydrogenation catalyst, titanium dioxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, organic compound preparation, physical/chemical process catalyst, etc., can solve the problem of unsatisfactory impregnation depth of active metal, active metal dispersion problems such as poor shedding rate and low shedding rate, to achieve the effect of low shedding rate, high degree of bonding and lower shedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

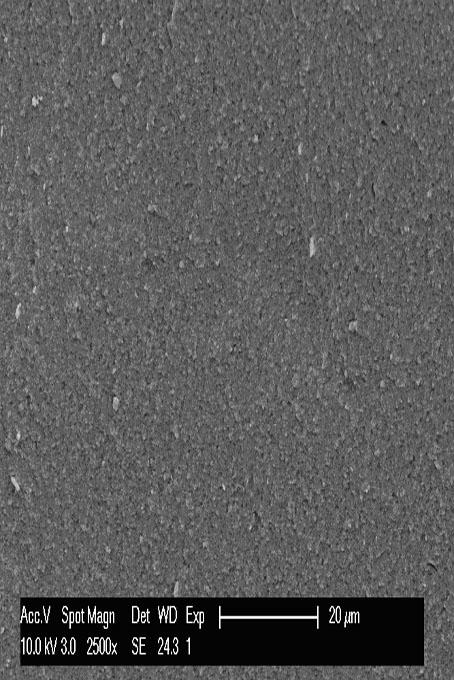

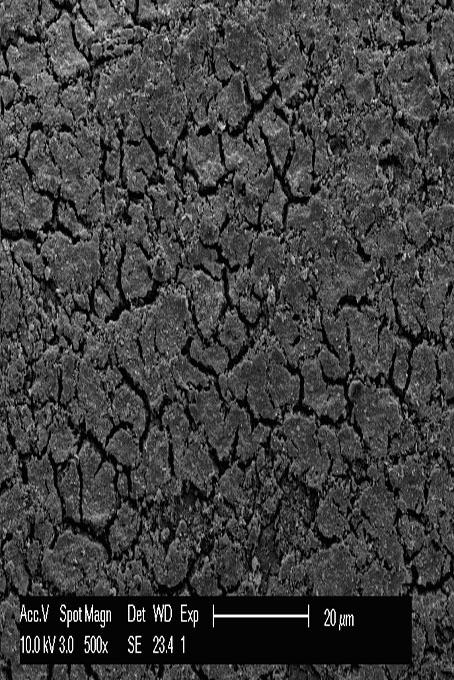

[0046] (1) The honeycomb titania carrier was sintered at 1050 °C to reduce the specific surface area to 0.5 m 2 / g, and then pickled with 1 mol / L dilute nitric acid for 2 h to remove the ash and impurities on the surface of the carrier, washed with deionized water until neutral, immersed in a solution of 5% polyethylene glycol, at 120 °C Dry for 5 h for later use;

[0047] (2) Add nano-sized titanium hydroxide and glucose into deionized water, add nitric acid dropwise during stirring to adjust the pH value, and obtain a transparent sol with a pH value of 1. The content of nanoscale titanium hydroxide in the described sol is 10%, and the content of glucose is 5%;

[0048] (3) Immerse the honeycomb titanium dioxide carrier obtained in step (1) in the sol of step (2) for 0.5 h, remove the residual liquid in the channel after taking it out, dry it at 70 °C for 2 h, repeat the dipping and drying 3 times as needed, Until the required coating load is reached, then baked under a nit...

Embodiment 2

[0054] (1) The honeycomb titania carrier was sintered at 950 °C to reduce the specific surface area to 1 m 2 / g, then pickled with 1 mol / L dilute nitric acid for 2 h to remove ash and impurities on the surface of the carrier, washed with deionized water until neutral, immersed in a solution of 1% polyvinyl alcohol, and dried at 120 °C 5 h standby;

[0055] (2) Add nano-sized titanium hydroxide and sucrose into deionized water, add nitric acid dropwise during stirring to adjust the pH value, and obtain a transparent sol with a pH value of 5. The content of nanoscale titanium hydroxide in the described sol is 1%, and the content of sucrose is 1%;

[0056] (3) Immerse the honeycomb titanium dioxide carrier obtained in step (1) in the sol of step (2) for 0.1 h, remove the residual liquid in the channel after taking it out, dry it at 50 °C for 5 h, repeat the dipping and drying 10 times as needed, Until the required coating load is reached, then it is fired at 300 °C under nitrog...

Embodiment 3

[0062] (1) The honeycomb titania carrier was sintered at 1250 °C to reduce the specific surface area to 0.01 m 2 / g, then pickled with 1 mol / L dilute nitric acid for 2 h to remove ash and impurities on the surface of the carrier, washed with deionized water until neutral, immersed in a solution of 10% glycerol, and dried at 120 °C 5 h standby;

[0063] (2) Add nano-scale titanium hydroxide and maltose into deionized water, add nitric acid dropwise during stirring to adjust the pH value, and obtain a transparent sol with a pH value of 0.5. The content of nanoscale titanium hydroxide in the described sol is 20%, and the content of maltose is 10%;

[0064] (3) Immerse the honeycomb titania carrier obtained in step (1) in the sol of step (2) for 1 h, remove the residual liquid in the pores after taking it out, dry it at 120 °C for 1 h, repeat the dipping and drying once as needed, Until the required coating load is reached, then baked at 500 °C under a nitrogen atmosphere to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com