Liquid deposition preparing method for anti-corrosion TiO2-ZrO2 coating and anti-corrosion metal with anti-corrosion TiO2-ZrO2 coating

A liquid deposition, anti-corrosion technology applied to anti-corrosion metals. It can solve the problems of no coating anti-corrosion performance test, large injection amount, complicated process, etc., to overcome the porous or cracked coating, solve the corrosion problem, and the preparation method is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

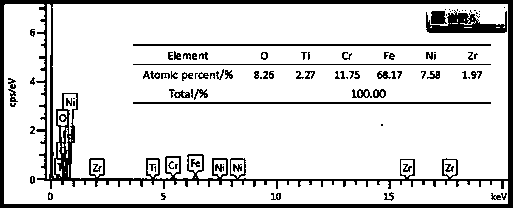

Embodiment 1

[0045] A corrosion-resistant TiO 2 -ZrO 2 The liquid phase deposition preparation method of coating comprises the following steps:

[0046] 1) Take 200mL of distilled water, divide it into four parts, 20mL, 80mL, 70mL and 30mL, dissolve 4.04g (NH 4 ) 2 TiF 6 (mass content 98%), 2.49gH 3 BO 3 (mass content 99.5%), 5.80gZr(SO 4 ) 2 4H 2 O (mass content 98%) and 11.18g (NH 4 ) 2 S 2 o 8 (The mass content is 98%). get (NH 4 ) 2 TiF 6 Aqueous solution, H 3 BO 3 Aqueous solution, Zr(SO 4 ) 2 aqueous solution and (NH 4 ) 2 S 2 o 8 Aqueous solution; the resulting solution was left to stand and filtered to remove particles visible to the naked eye, and then used.

[0047] 2) will (NH 4 ) 2 TiF 6 aqueous solution and H 3 BO 3 After the aqueous solution was mixed, it was filtered again to obtain a clear solution A.

[0048] 3) Zr(SO 4 ) 2 aqueous solution and (NH 4 ) 2 S 2 o 8 The aqueous solutions were mixed to give clear solution B.

[004...

Embodiment 2

[0056] Embodiment 2 A kind of anti-corrosion TiO 2 -ZrO 2 Liquid phase deposition preparation method of coating :

[0057] 1) Take 200mL of distilled water, divide it into four parts, namely 20mL, 80mL, 70mL and 30mL, and dissolve 0.40g (NH 4 ) 2 TiF 6 (mass content 98%), 0.12gH 3 BO 3 (mass content 99.5%), 0.73gZr(SO 4 ) 2 4H 2 O (mass content 98%) and 0.23g (NH4 ) 2 S 2 o 8 (The mass content is 98%). get (NH 4 ) 2 TiF 6 Aqueous solution, H 3 BO 3 Aqueous solution, Zr(SO 4 ) 2 aqueous solution and (NH 4 ) 2 S 2 o 8 Aqueous solution; the resulting solution was left to stand and filtered to remove particles visible to the naked eye, and then used.

[0058] 2) will (NH 4 ) 2 TiF 6 aqueous solution and H 3 BO 3 After the aqueous solution was mixed, it was filtered again to obtain a clear solution A.

[0059] 3) Zr(SO 4 ) 2 aqueous solution and (NH 4 ) 2 S 2 o 8 The aqueous solutions were mixed to give clear solution B.

[0060] 4) Mix...

Embodiment 3

[0067] Embodiment 3 A kind of corrosion-resistant TiO 2 -ZrO 2 Liquid phase deposition preparation method of coating :

[0068] 1) Divide 200mL of distilled water into four parts, namely 20mL, 80mL, 70mL and 30mL, and dissolve 8.08g (NH 4 ) 2 TiF 6 (mass content 98%), 9.94gH 3 BO 3 (mass content 99.5%), 7.25gZr(SO 4 ) 2 4H 2 O (mass content 98%) and 27.94g (NH 4 ) 2 S 2 o 8 (The mass content is 98%). get (NH 4 ) 2 TiF 6 Aqueous solution, H 3 BO 3 Aqueous solution, Zr(SO 4 ) 2 aqueous solution and (NH 4 ) 2 S 2 o 8 Aqueous solution; the resulting solution was left to stand and filtered to remove particles visible to the naked eye, and then used.

[0069] 2) will (NH 4 ) 2 TiF 6 aqueous solution and H 3 BO 3 After the aqueous solution was mixed, it was filtered again to obtain a clear solution A.

[0070] 3) Zr(SO 4 ) 2 aqueous solution and (NH 4 ) 2 S 2 o 8 The aqueous solutions were mixed to give clear solution B.

[0071] 4) Mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com