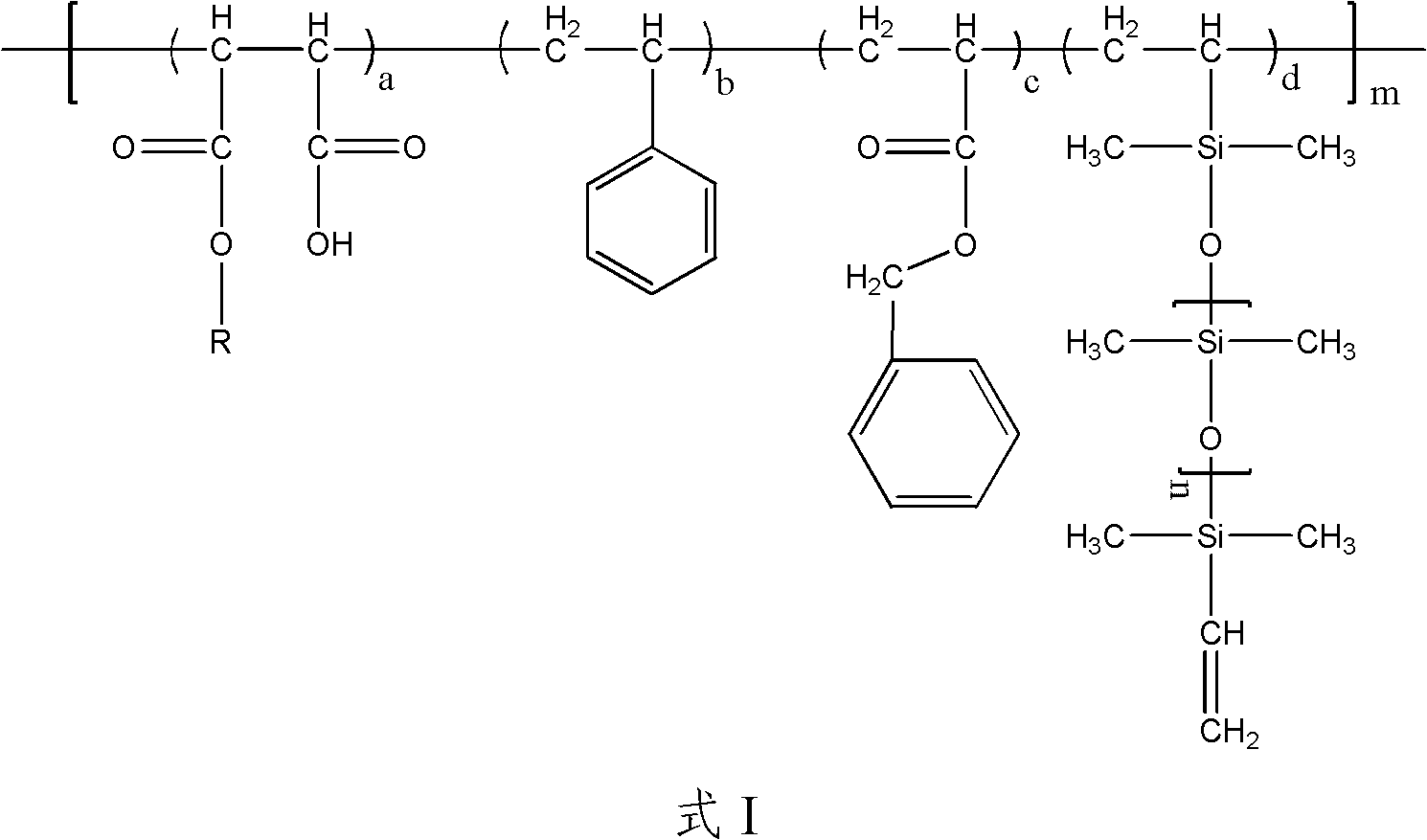

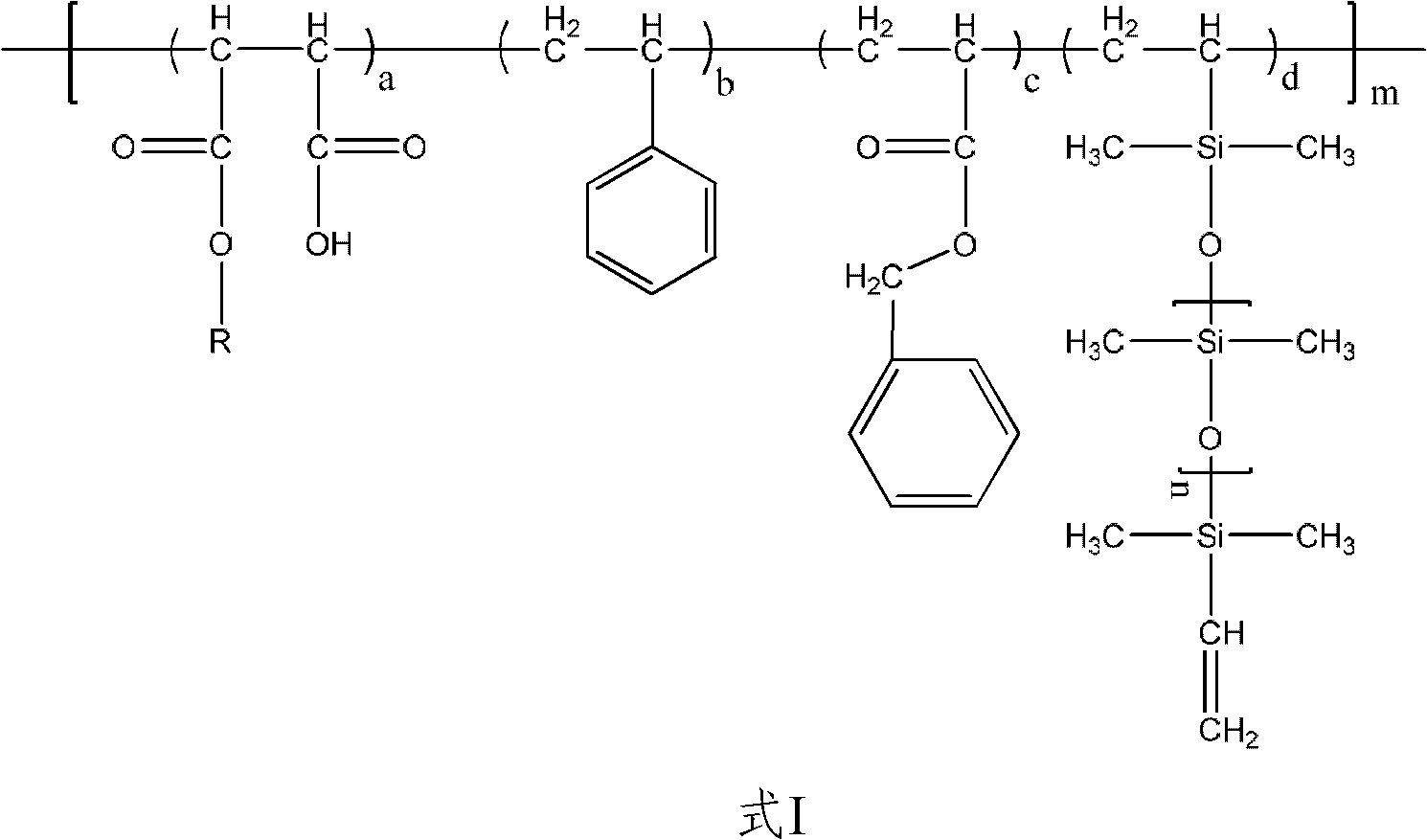

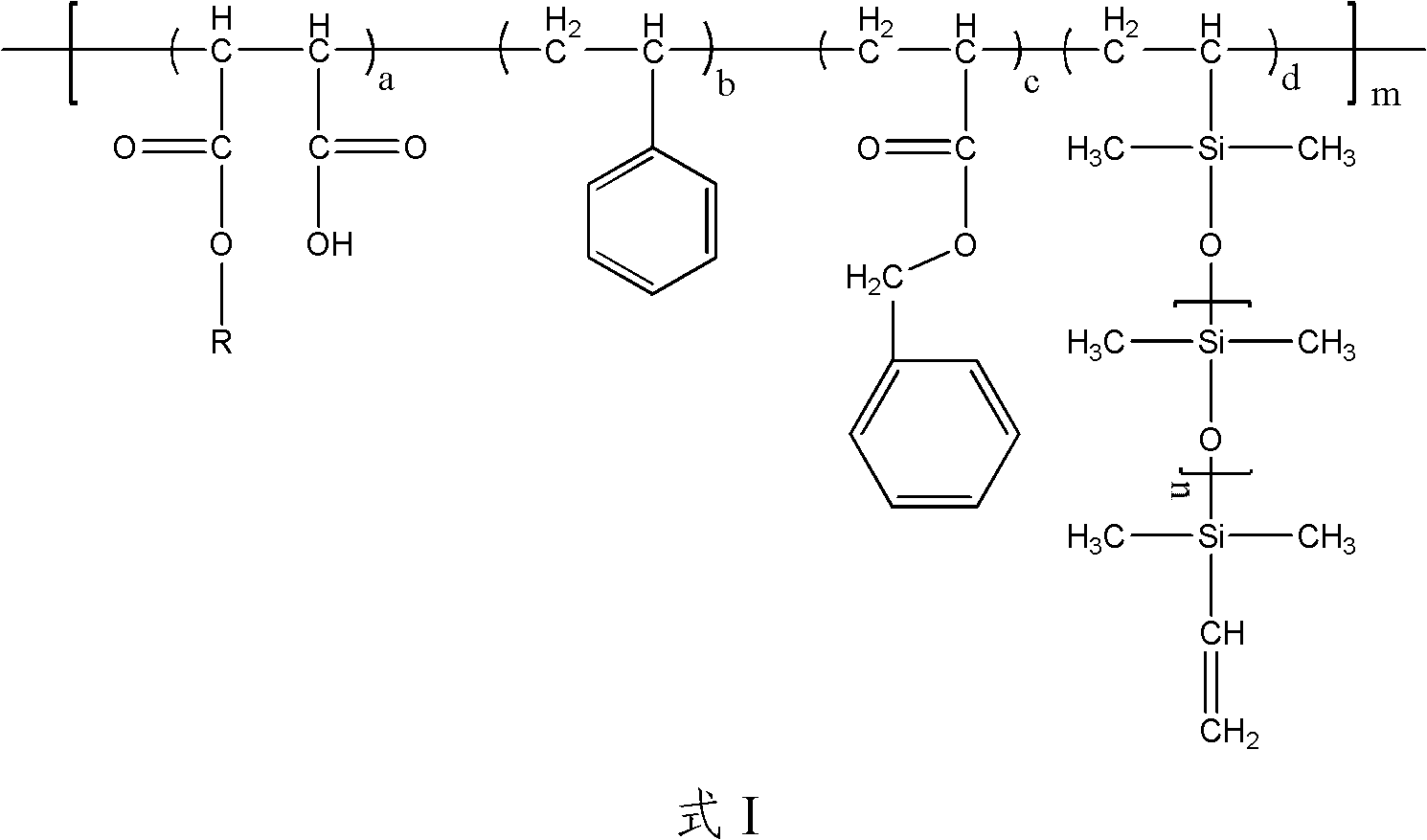

Alkali soluble resin, photosensitive resin composition containing it and application thereof

A photosensitive resin, soluble technology, applied in the field of photosensitive resin composition, can solve the problems of residue, limiting self-leveling of photoresist glue, high viscosity of the system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The photosensitive resin composition of the present invention contains following components:

[0060] 100 parts by weight of alkali-soluble resin, 100 parts by weight of epoxy acrylate polymer, 100 parts by weight of pigment P.R.179, 100 parts by weight of dispersant BYK-110, 14 parts by weight of photoinitiator benzoyl isopropyl ether, 800 parts by weight of propylene glycol Monoethyl ether, 3 parts by weight of silane coupling agent.

[0061] Mix the above components uniformly to obtain a photosensitive resin composition.

[0062] Wherein, the preparation method of alkali-soluble resin is as follows:

[0063] 30g of maleic anhydride, 30g of styrene, 35g of benzyl acrylate, and 8g of initiator AIBN were mixed and reacted at 60°C for 4h, and the reaction product was stirred and refluxed in 150g of propylene glycol monoethyl ether solvent at 75°C, and placed in Add 12g of vinyl-terminated polydimethylsiloxane dropwise at a speed of 2-3 seconds during the stirring proce...

Embodiment 2

[0068] The photosensitive resin composition of the present invention contains following components:

[0069] 150 parts by weight of alkali-soluble resin, 100 parts by weight of polyurethane acrylate polymer, 100 parts by weight of phthalocyanine blue pigment, 100 parts by weight of dispersant BYK-170, 14 parts by weight of photoinitiator benzoyl isopropyl ether, 740 parts by weight of cyclo Hexane, 3 parts by weight of silane coupling agent.

[0070] Mix the above components uniformly to obtain a photosensitive resin composition.

[0071] Wherein, the preparation method of alkali-soluble resin is as follows:

[0072] 10g of maleic anhydride, 45g of styrene, 20g of benzyl acrylate, and 6.8g of initiator BPO were mixed and reacted at 90°C for 4h, and the reaction product was stirred and refluxed in 150g of cyclohexane solvent at 70°C, and Add 13g of vinyl-terminated polydimethylsiloxane dropwise at a speed of 2-3 seconds during stirring, adjust the temperature to 115°C after 2...

Embodiment 3

[0075] The photosensitive resin composition of the present invention contains following components:

[0076] 370 parts by weight of alkali-soluble resin, 120 parts by weight of pentaerythritol tetraacrylate, 100 parts by weight of pigment C.I. green pigment, 100 parts by weight of dispersant BYK-171, 20 parts by weight of photoinitiator benzoyl isopropyl ether, 850 parts by weight of ethylene glycol Alcohol monoethyl ether, 3 parts by weight of silane coupling agent.

[0077] Mix the above components uniformly to obtain a photosensitive resin composition.

[0078] Wherein, the preparation method of alkali-soluble resin is as follows:

[0079] Mix 10g of maleic anhydride, 45g of styrene, 20g of benzyl acrylate, and 6.8g of initiator BPO to react at 60°C for 5h, and stir and reflux the reaction product in 150g of ethylene glycol monoethyl ether solvent at 75°C , and add 12g of vinyl-terminated polydimethylsiloxane dropwise at a speed of 2-3 seconds during the stirring process,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com