Zr modified silicide coating on refractory metal surface and preparation method thereof

A refractory metal, silicide technology, applied in metal material coating process, coating, heating inorganic powder coating and other directions, can solve the problems of limiting the high temperature protection life of silicide coating, oxide film cracking or high temperature spheroidization, etc. , to achieve the effect of easy control, smooth surface and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

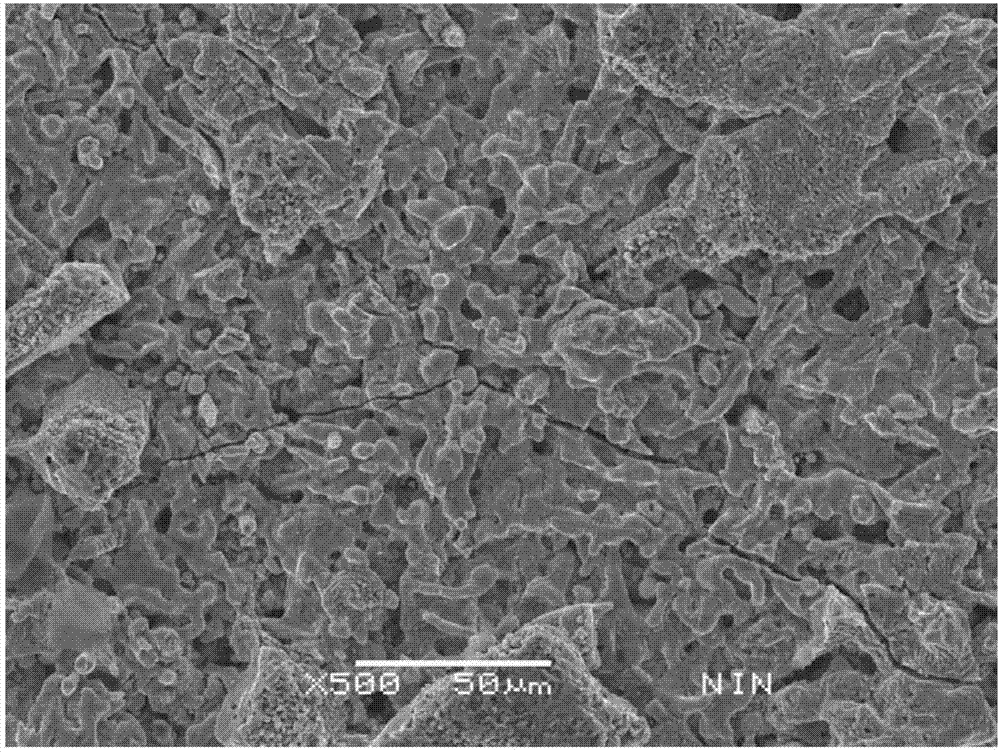

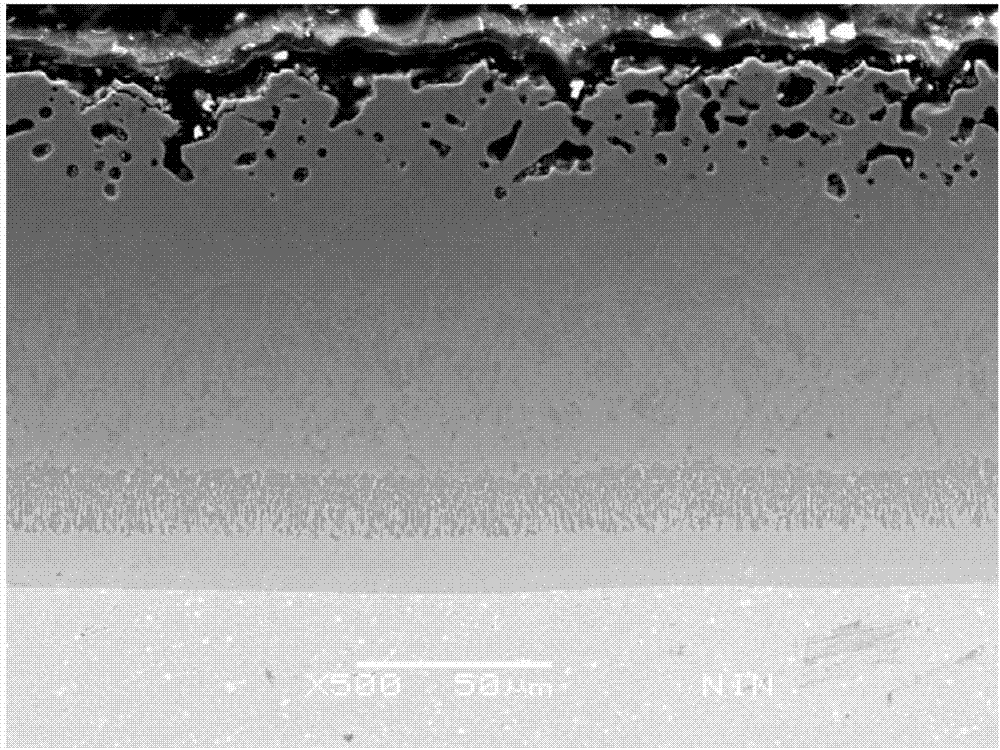

Image

Examples

Embodiment 1

[0027] The Zr modified silicide coating prepared on the surface of the C103 alloy in this embodiment is composed of the following mass percentages: Ti 15%, W 15%, Cr 10%, Zr 5%, Nb 5%, and the balance is Si and not Avoid impurities.

[0028] The method for preparing Zr modified silicide coating on the surface of C103 alloy in this embodiment comprises the following steps:

[0029] Step 1. Use 600 # SiC sandpaper grinds the surface of C103 alloy, and then carries out sandblasting, degreasing and pickling treatment to the surface of C103 alloy successively; The time is 4min; preferably, the C103 alloy is immersed in acetone for degreasing treatment; the acid solution used in the pickling is formed by mixing hydrofluoric acid and concentrated nitric acid in a volume ratio of 7:3, and the mass concentration of the hydrofluoric acid 40%, the mass concentration of the concentrated nitric acid is 65%, and the pickling time is 3min;

Embodiment 2

[0035] The Zr-modified silicide coating prepared on the surface of Ta10W alloy in this embodiment is composed of the following components by mass percentage: Ti 25%, W 20%, Cr 12.5%, Zr 3%, Nb 6.5%, and the balance is Si and not Avoid impurities.

[0036] The method for preparing a Zr modified silicide coating on the Ta10W alloy surface in this embodiment comprises the following steps:

[0037] Step 1. Use 600 # The surface of the Ta10W alloy is polished with SiC sandpaper, and then the surface of the Ta10W alloy is sandblasted, degreased and pickled in turn; The sand time is 4min; preferably, the Ta10W alloy is immersed in acetone for degreasing treatment; the acid solution used in the pickling is formed by mixing hydrofluoric acid and concentrated nitric acid in a volume ratio of 6:4, and the mass of the hydrofluoric acid Concentration is 60%, the mass concentration of described concentrated nitric acid is 68%, the time of pickling treatment is 1min;

[0038] Step 2. Mix ...

Embodiment 3

[0042] The Zr modified silicide coating prepared on the surface of the TZM molybdenum alloy in this embodiment is composed of the following mass percentages: Ti 12%, W 17%, Cr 15%, Zr 3%, Nb 8%, and the balance is Si and unavoidable impurities.

[0043] The method for preparing a Zr modified silicide coating on the surface of a TZM molybdenum alloy in this embodiment comprises the following steps:

[0044] Step 1. Use 600 # Grinding the surface of the TZM molybdenum alloy with SiC sandpaper, and then performing sandblasting, degreasing and pickling on the surface of the TZM molybdenum alloy in turn; the sand used in the sandblasting treatment is zirconia sand, and the pressure of the sandblasting treatment is 0.2MPa , the sandblasting time is 6min; preferably, the TZM molybdenum alloy is immersed in acetone for degreasing treatment; the acid solution used in the pickling is formed by mixing hydrofluoric acid and concentrated nitric acid in a volume ratio of 6.5:3.5, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com