Steel pipe inner coating solidifying device used for high-temperature environment

A technology of curing device and high temperature environment, which is applied to the device, coating, pretreatment surface and other directions of surface coating liquid, which can solve the problems of uncontrollable moving speed of steel pipe, easy to damage the outer surface of steel pipe, and non-uniform movement of steel pipe. , to achieve the effect of good promotion and application prospects, saving manpower and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

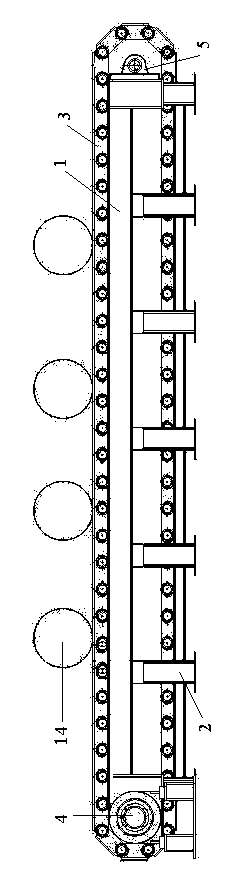

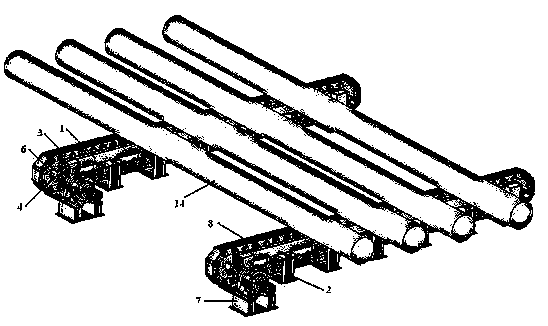

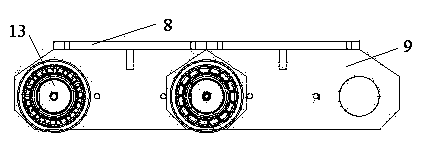

[0034] like Figure 1-2 Shown is a steel pipe inner coating curing device for high-temperature environments, including a sliding track 1, a bracket 2, a chain 3, a driving wheel 4, a driven wheel 5, a driving rod 6 and a frequency converter 7, and the bracket 2 is hollow "Mouth"-shaped structure, the sliding track 1 is supported by the bracket 2, the driving wheel 4 and the driven wheel 5 are arranged at both ends of the sliding track 1, and one end of the chain 3 is nested in the driving wheel 4, passing through the sliding track 1, The other end is nested in the driven wheel 5 , and the frequency converter 7 is connected with the driving wheel 4 through the driving rod 6 . The outer surface of the chain 3 is provided with a protective plate 8, which protects the surface of the conveying device and the outer surface of the steel pipe. The protective plate 8 is made of polyurethane material, which can make the protective plate 8 have high hardness, wear resistance and tempera...

Embodiment 2

[0036] like Figure 1-6 As shown, a steel pipe inner coating curing device for high temperature environment includes a sliding track 1, a bracket 2, a chain 3, a driving wheel 4, a driven wheel 5, a driving rod 6 and a frequency converter 7, and the bracket 2 is hollow The "mouth" shape structure, the sliding track 1 is supported by the bracket 2, the driving wheel 4 and the driven wheel 5 are arranged at both ends of the sliding track 1, one end of the chain 3 is nested in the driving wheel 4, and passes through the sliding track 1 , the other end is nested in the driven wheel 5, the frequency converter 7 is connected to the driving wheel 4 through the drive rod 6, and the range of the frequency converter 7 is 0-2m / min. The outer surface of the chain 3 is provided with a protective plate 8, which protects the surface of the conveying device and the outer surface of the steel pipe. The protective plate 8 is made of polyurethane material, which can make the protective plate 8 ...

Embodiment 3

[0038] A high-temperature curing method utilizing the curing device described in embodiment 1 or 2:

[0039] (1) Coating preparation: Weigh material A and material B respectively, and add them into a mixing container with stirring one after another, stir at 60-80r / min for 5-8 minutes, and set aside.

[0040] (2) High-pressure spraying: The high-pressure spray gun is used to rotate while moving to spray the paint evenly on the inner wall of the tube, and the thickness of the coating film can be conveniently controlled according to the technical requirements.

[0041] (3) Move the Ф1200mm×18mm steel pipe 14 after spraying on the inner wall to the conveying device of the curing room 15 through a special transport trolley. Under the conditions of curing temperature: 65-85°C and moving speed: 0.3m / min, the high-temperature curing of the inner coating can be completed in 1.2 hours. Product inspection: coating surface, flat, smooth, no bubbles, no scratches; hardness, no scratches o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com