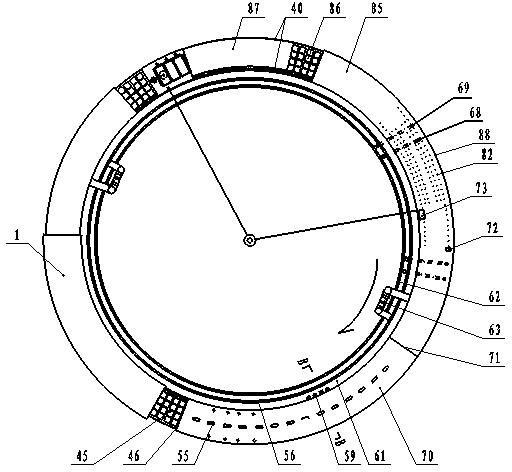

Turnover kiln with air distribution system arranged at bottom

An air distribution system, a technology for rotary kilns, used in lighting and heating equipment, furnace types, furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

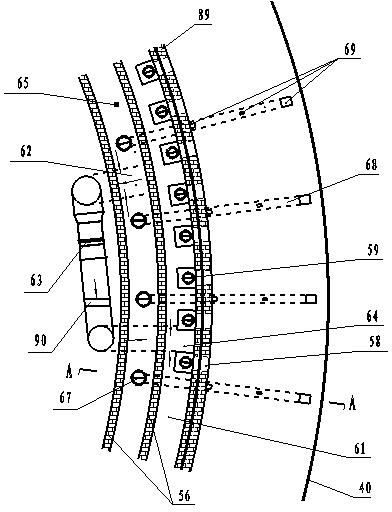

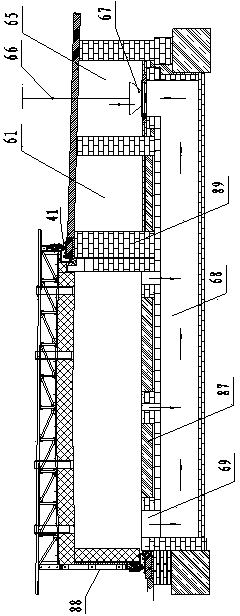

[0030] Example: The outer diameter of the circular track is 80m, the circumference is 251m, the length of the kiln body is 114m, the drying section is 48m, the roasting section is 66m, the kiln exit section is 46m, the natural drying section is 80m, the fully enclosed drying shed is 12m, and the low inner shed is 36m. The high outer shed is 36m. Send hot air duct every 2-3 meters. Hafeng Road every 4-6 meters. There are two blowers, one works and the other serves as a backup. Two fans are placed at opposite ends of the inner ring. The center of the kiln body is the power supply part. Electricity is sent to hydraulic equipment and stacking equipment through cables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com