Automotive double-fan three-level speed control circuit and control method

A three-stage speed regulation and control circuit technology, which is applied in the control of coolant flow, engine components, machines/engines, etc., can solve the problems of inability to adjust the voltage, the working voltage cannot be changed, and the noise is large, so as to reduce the use of power, Easy to popularize and use, reduce the effect of fan noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

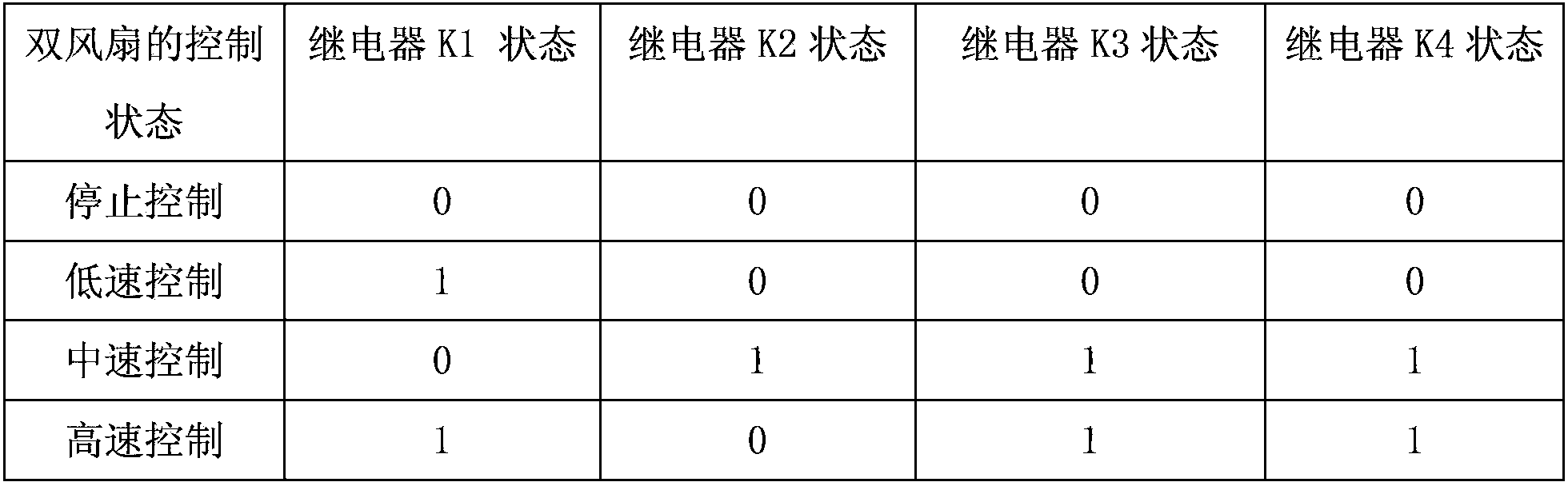

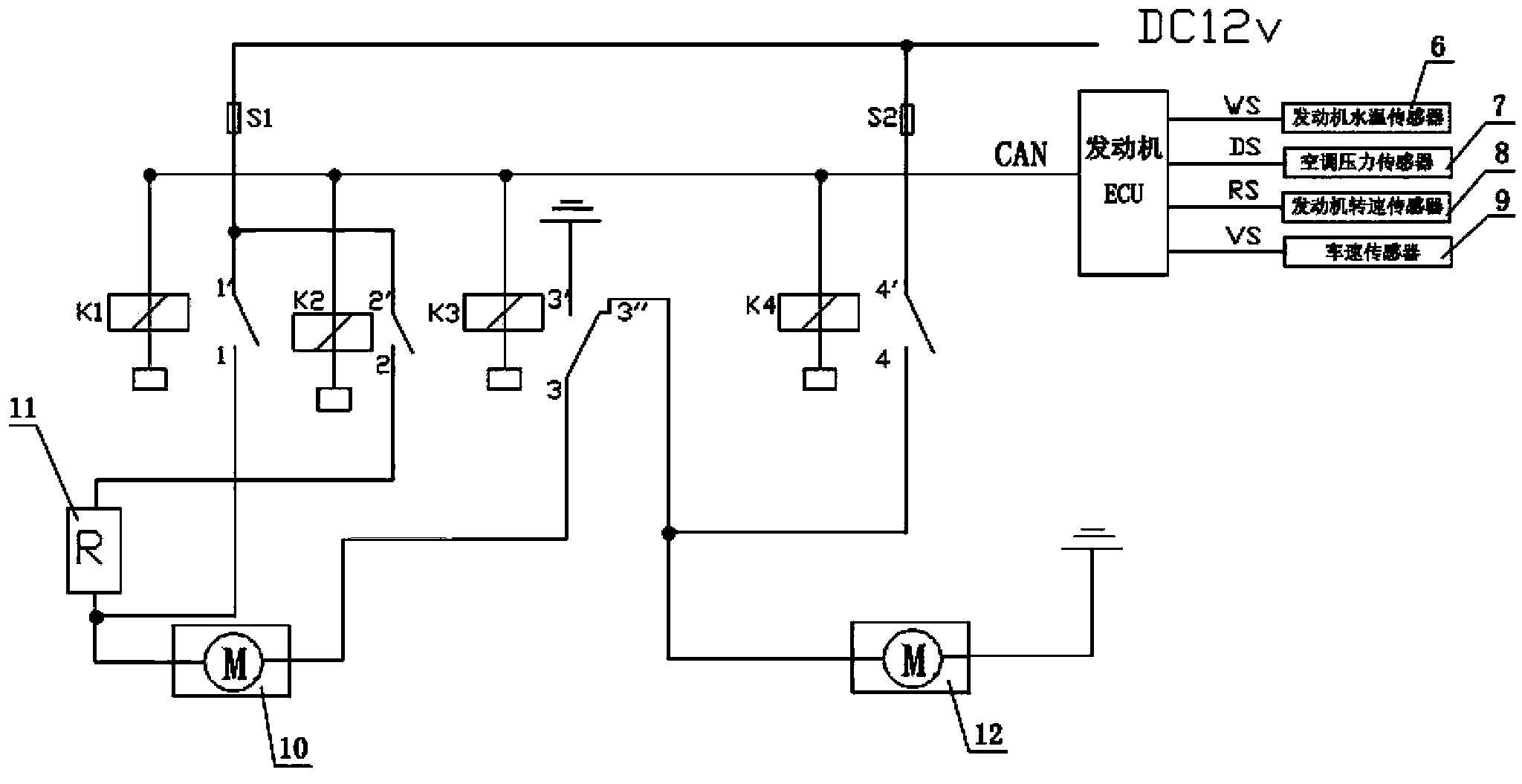

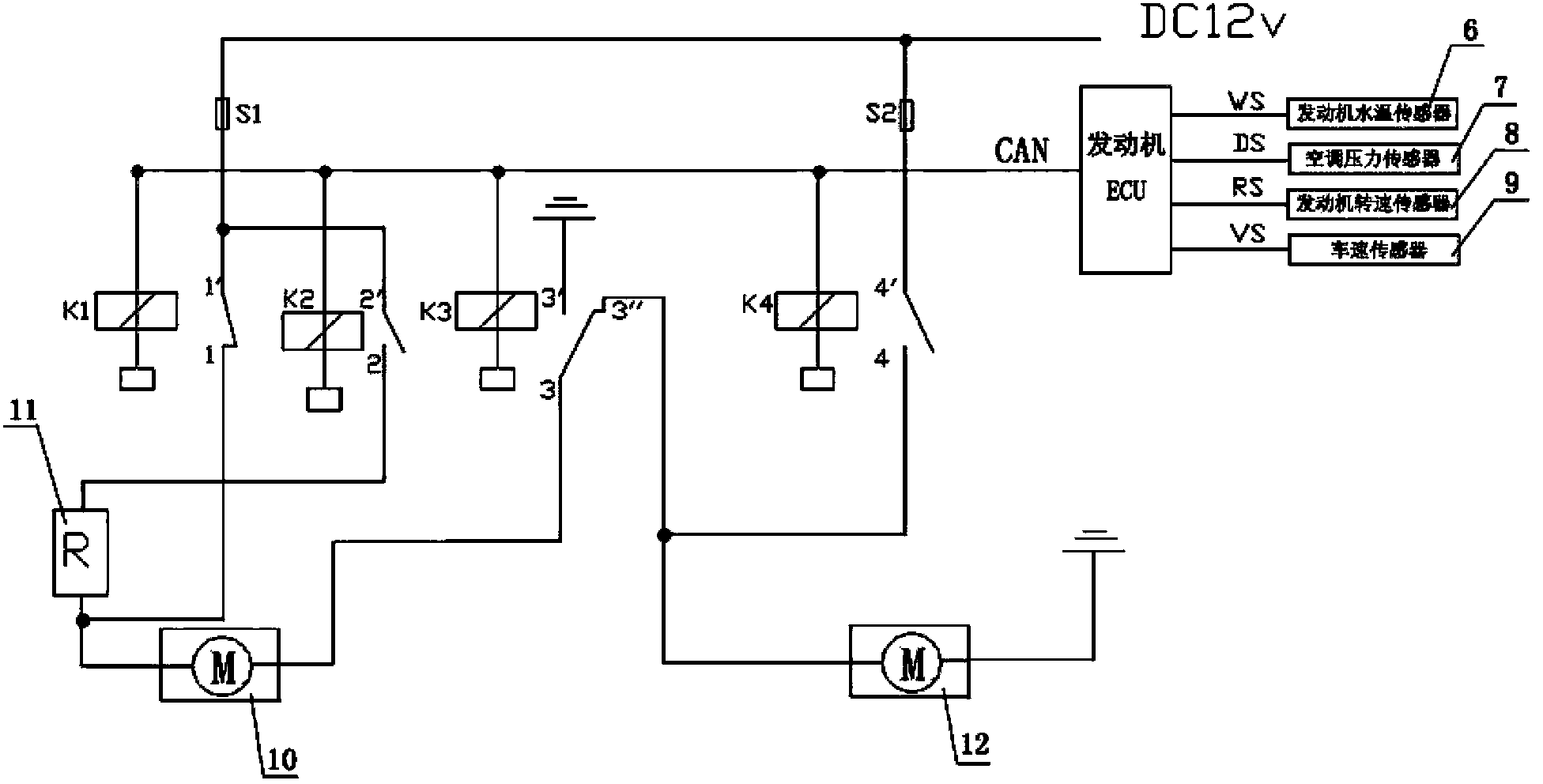

[0026] Such as Figure 1 to Figure 6 The three-stage speed regulation control circuit for automobile dual fans shown includes relays K1, K2, K3, K4, a first electronic fan 10, a second electronic fan 12, an engine ECU and an adjustable resistor 11, and the power of the first electronic fan 10 Greater than the power of the second electronic fan 12, the input end of the engine ECU is connected with the engine water temperature sensor 6, the air conditioner pressure sensor 7, the engine speed sensor 8 and the vehicle speed sensor 9, so as to obtain the engine water temperature signal WS, the air conditioner pressure signal DS, and the engine speed sensor in real time. Signal RS and vehicle speed signal VS, the output of the engine ECU is connected to the coils of relays K1, K2, K3, and K4 through the CAN bus, and the relays K1, K2, K3, and K4 are controlled to be turned on / off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com