Low-energy consumption animal crushing machine

A processing machine and low energy consumption technology, which is applied in the field of animal solid waste processing equipment, can solve the problems of affecting the working environment and sanitation, using high power, and inconvenient use and operation, so as to prevent dirt from splashing outward, use low power, and The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

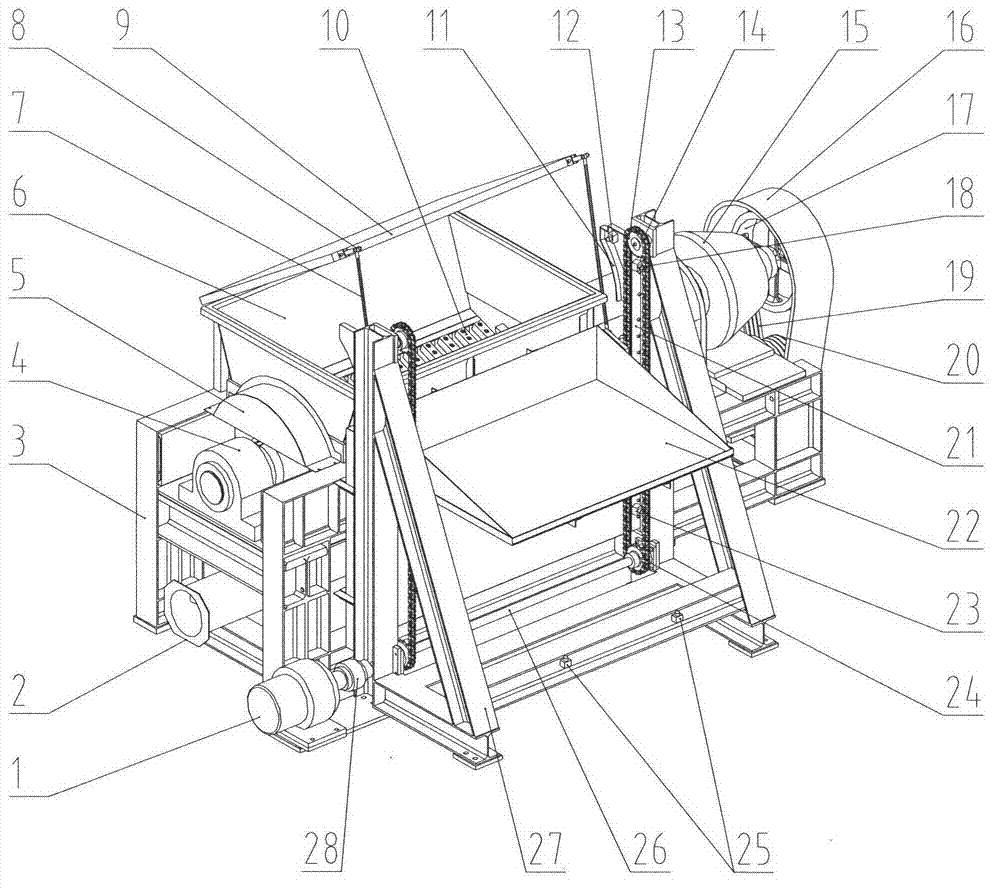

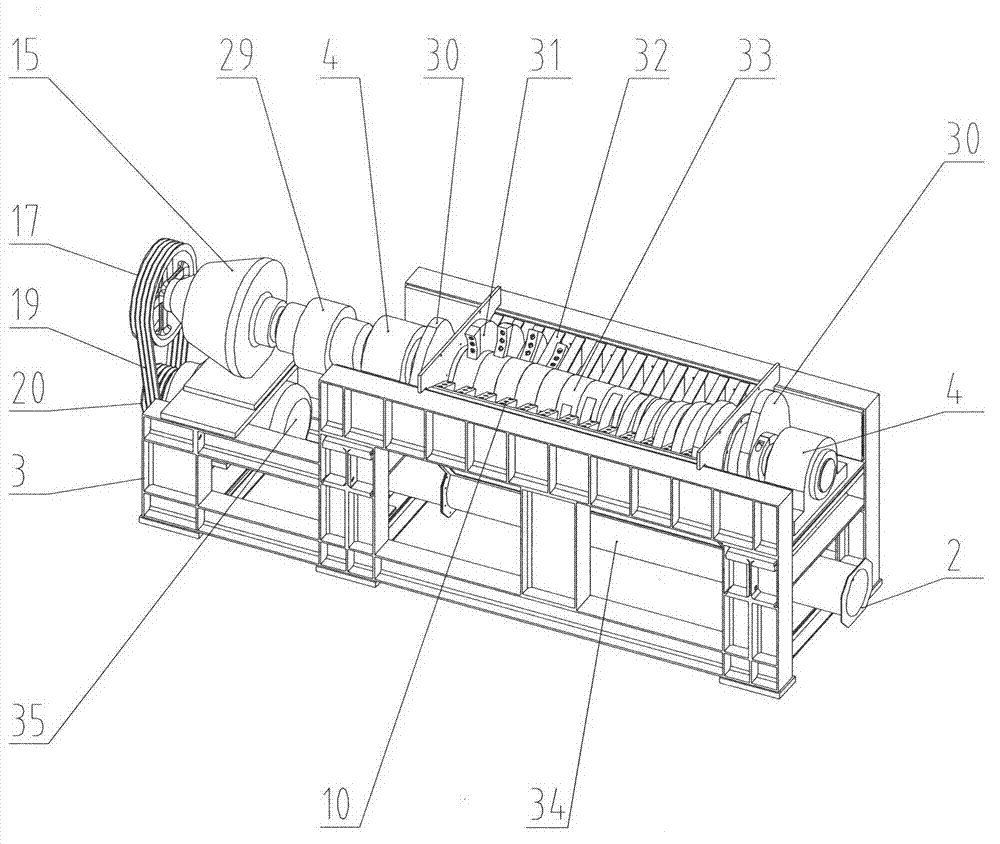

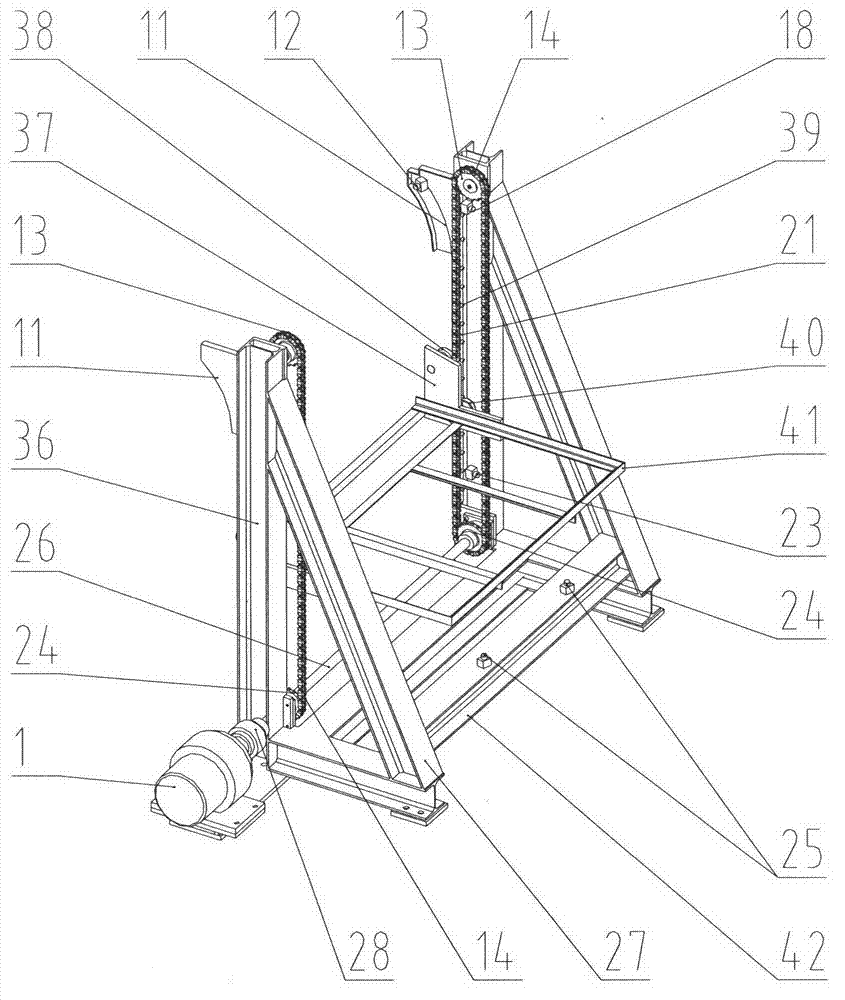

[0021] Such as figure 1 and figure 2 As shown, the structure of the present invention comprises feed inlet 6, frame 3, a hob shaft 33, two balance wheels 30, left side fixed knife 10 and right side fixed knife 32, screw conveyor 34, power transmission device And feeding mechanism and other components. The hob shaft 33 is supported by two bearing blocks 4 and installed on the top of the frame 3 , and one end of the shaft is connected to the speed reducer 15 through a coupling 29 . The fixed knife 10 on the left side and the fixed knife 32 on the right side are fixed on the top of the frame 3 , and are arranged alternately with the hob 31 on both sides of the hob shaft 33 . The screw conveyor 34 is adjacent to the hob shaft 33 and is located directly below the hob shaft 33 , its rotation axis is parallel to the axis of the hob shaft 33 , and is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com