Totally-enclosed gas-atomizing powder preparation device for solving blockage of nozzle and liquid guiding pipe caused by high-melting-point material

A technology of gas atomization and powder making equipment, which is applied in the field of producing ultrafine powder from gas atomization melt, and can solve the problem of blockage of high melting point substances, metal blockage of nozzles and guide tubes, and blockage of high melting point substances of nozzles and guide tubes and other problems, to achieve the effect of preventing cooling and solidification, eliminating interference, and eliminating low melting point blockages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

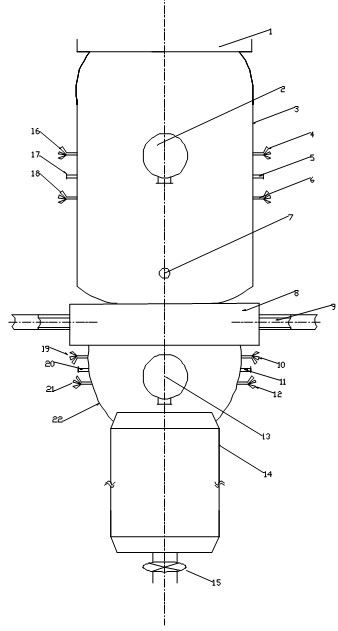

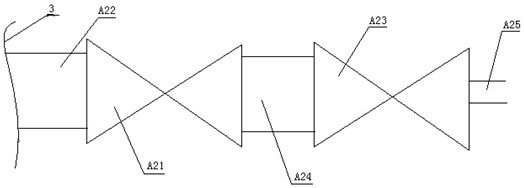

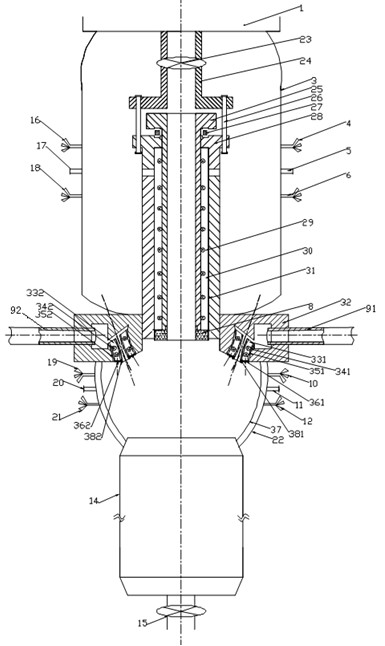

[0062] A fully enclosed gas atomization powder making device that solves the blockage of high melting point substances in nozzles and guide tubes. The schematic diagram of its appearance is shown in figure 1As shown in the figure, among the figures: 1 is a heat preservation crucible, 2 is a pick-up port A, 3 is a telescopic plastic tube A, 4 is a glove I, 5 is an external power supply interface I of a heating element A of an atomizer, and 6 is a glove II, 7 is the vacuum pump interface, 8 is the nozzle of the atomizer, 9 is the intake pipe of the nozzle of the atomizer, 10 is the glove III, 11 is the heating element B of the atomizer, the external power supply interface I, 12 is the glove IV, 13 is the extraction port B, 14 is the atomization tower, 15 is the valve of the atomization tower, 16 is the glove V, 17 is the heating element A of the atomizer, the external power interface II, 18 is the glove VI, 19 is the glove VII, 20 The heating element B of the atomizer is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com