Refractory material compression molding device

A refractory material and compression molding technology, applied in the field of material processing, can solve the problems of unevenness, easy deposition of raw materials on the corners of the container, and no mixing function, etc., to reduce waste, uniform refractory materials, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

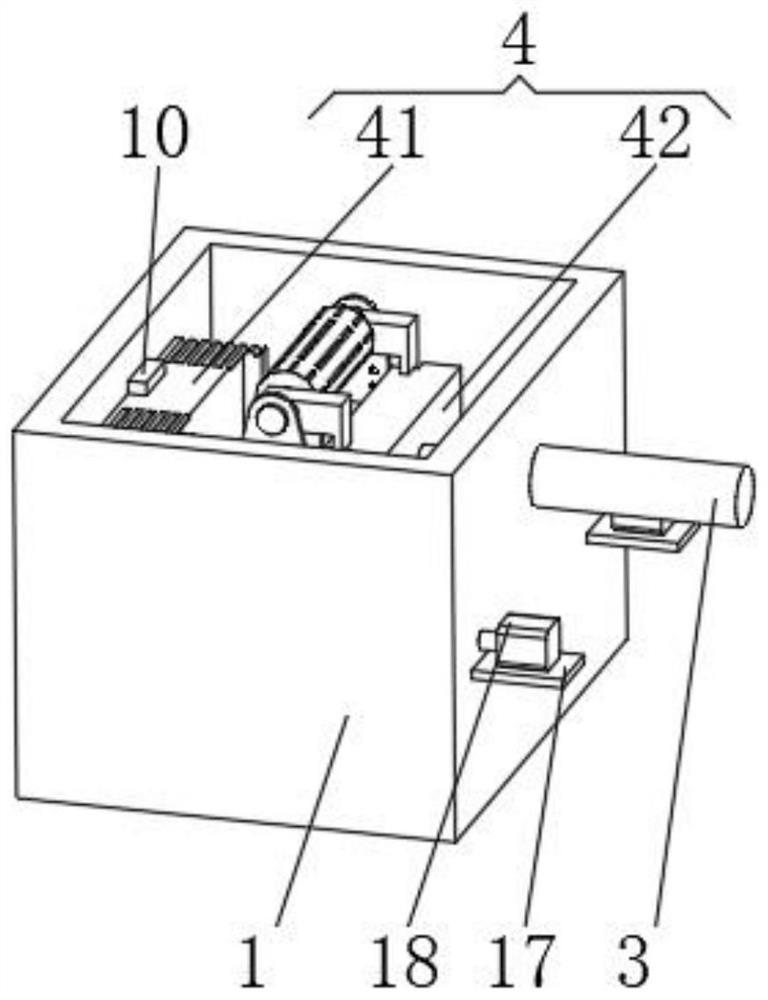

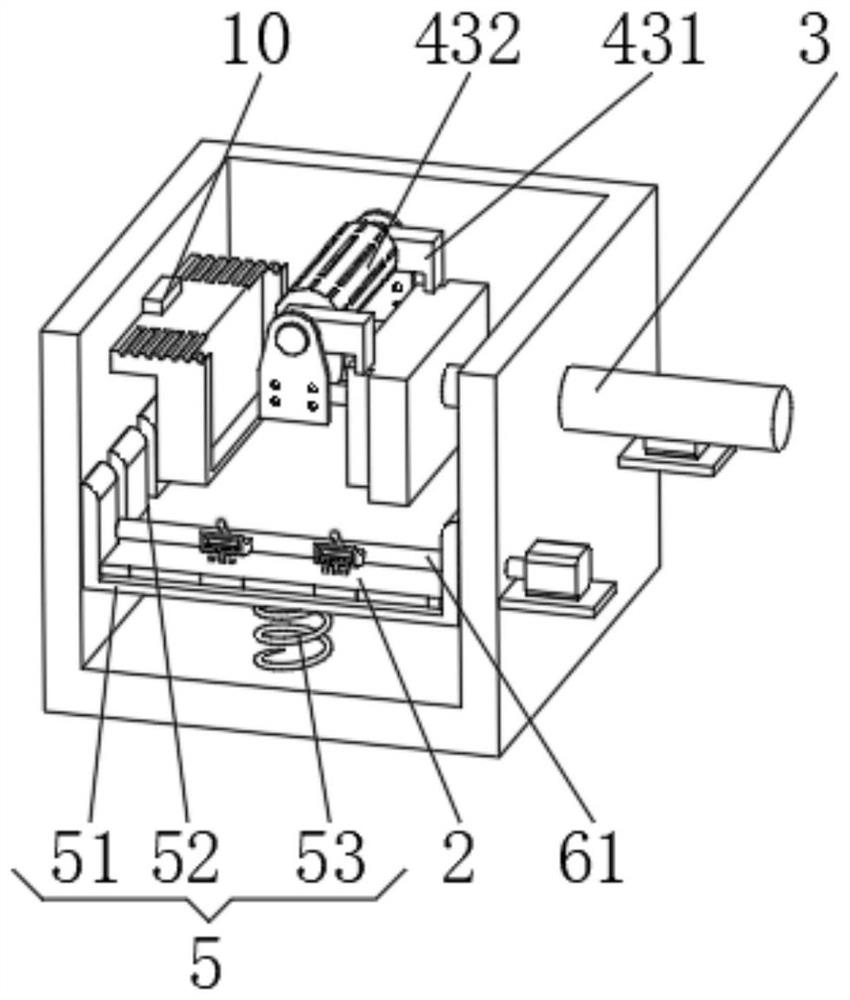

[0035] see Figure 1-5 , the present invention provides a technical solution: a refractory material pressing and forming device, including a filling box 1, a lifting plate 2 is slidably connected between the two sides of the inner wall of the filling box 1, and a lifting plate 2 is fixedly connected to one side of the filling box 1 Oil cylinder 3, one end of oil cylinder 3 runs through the material box 1 and extends to the inside of the material box 1, and the inside of the material box 1 is provided with:

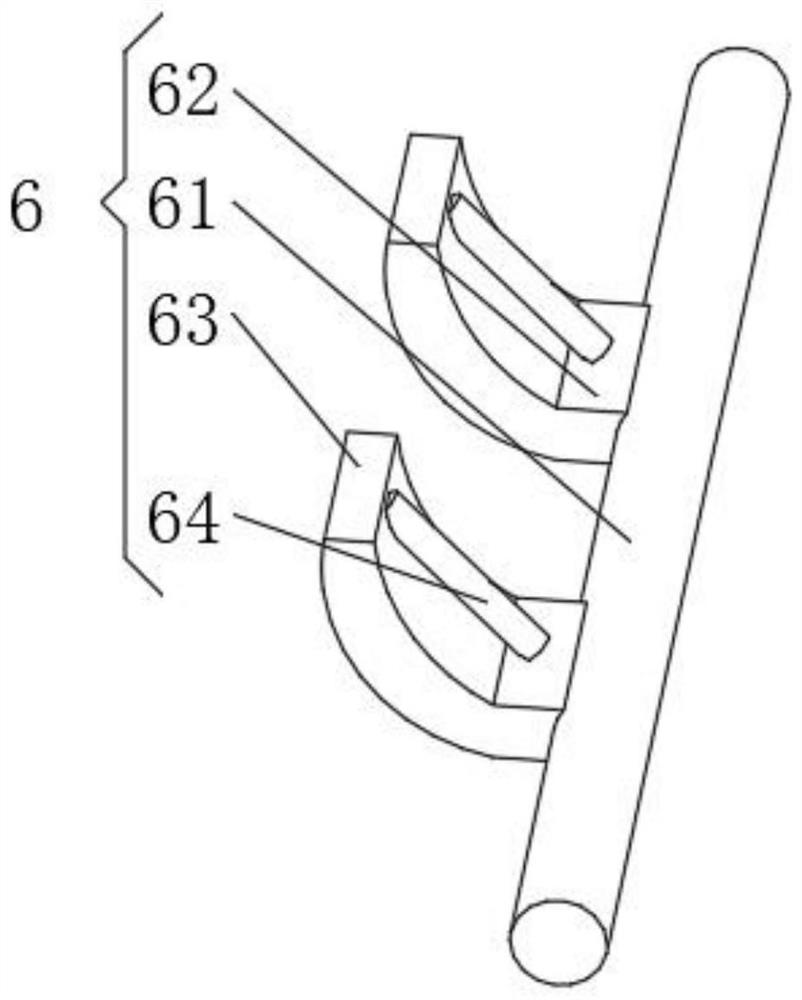

[0036] Pressing device 4, this pressing device 4 has pressing die 41, and pressing die 41 is fixedly connected with the inner wall of holding box 1, and one end that oil cylinder 3 extends to holding box 1 inside is fixedly connected with pressing punch 42, and pressing punch The top of 42 is fixedly connected with cleaning device 43;

[0037] Lifting device 5, the lifting device 5 has an elastic membrane 51, which is slidingly connected with the lifting plate 2, and the ...

Embodiment 2

[0045] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a refractory material compression molding device includes the following steps:

[0046] Step 1: Feed and mix materials, put the refractory mixed material into the material box, the refractory material pushes the lifting plate to squeeze the elastic film downward, the elastic film is squeezed and deformed, and the lifting plate descends, and the mixing motor drives the mixing rod and the elastic film. The plate rotates, and the elastic plate drives the refractory materials at the corners of the material box to move to the center of the material box;

[0047] Step 2, pressing and forming, start the oil cylinder to drive the pressing punch to move towards the direction of the pressing die, the pressing punch will press the refractory material inside the pressing die, and control the oil cylinder to drive the pressing punch to move a small distance away from the pressing die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com