Surface coating spraying device for road construction bridge

A surface coating and road construction technology, which is applied to the surface coating liquid device, spray device, pretreatment surface, etc., can solve the problems of lack of stirring and drying mechanism, material can not be sprayed smoothly, material cooling and solidification, etc., to reduce The amount of labor, to ensure the normal injection process, the effect of scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

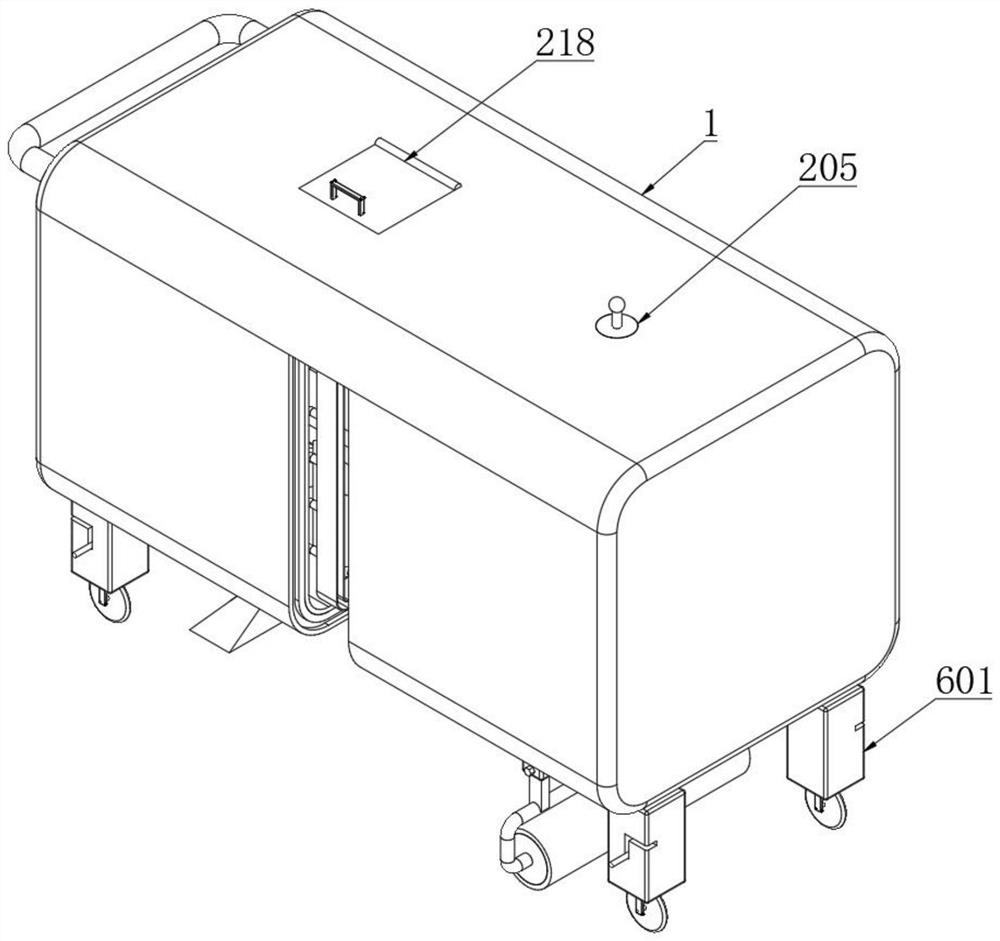

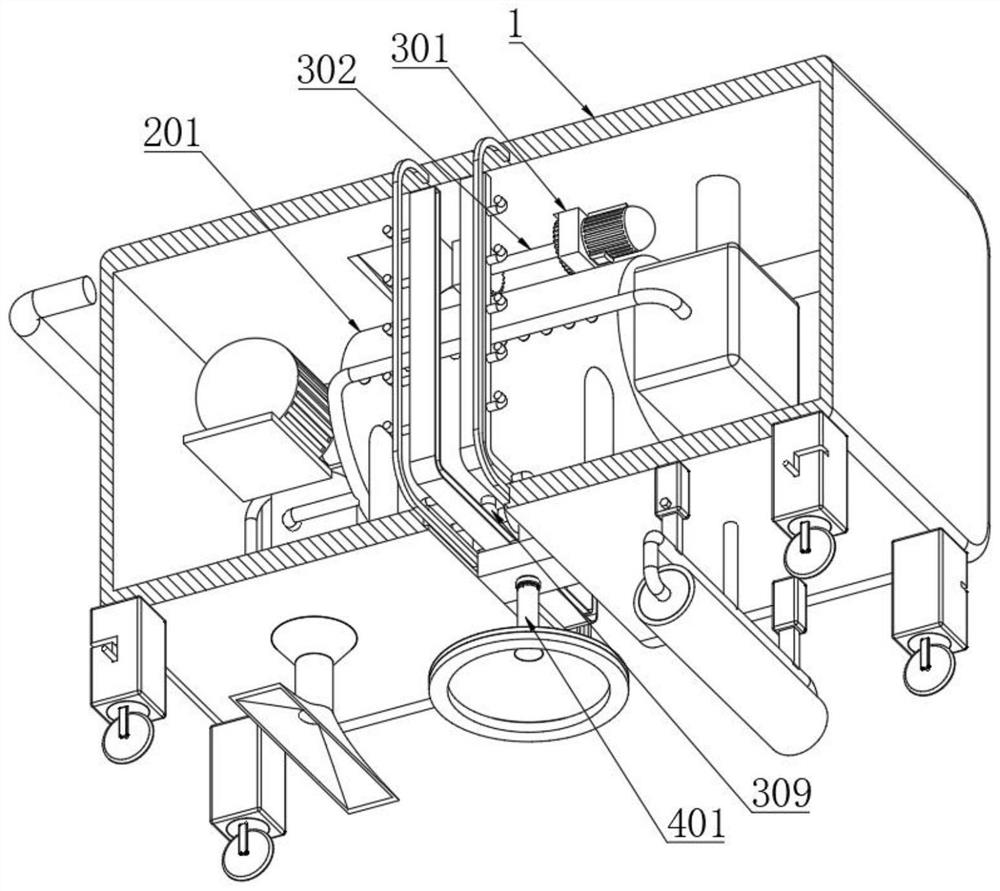

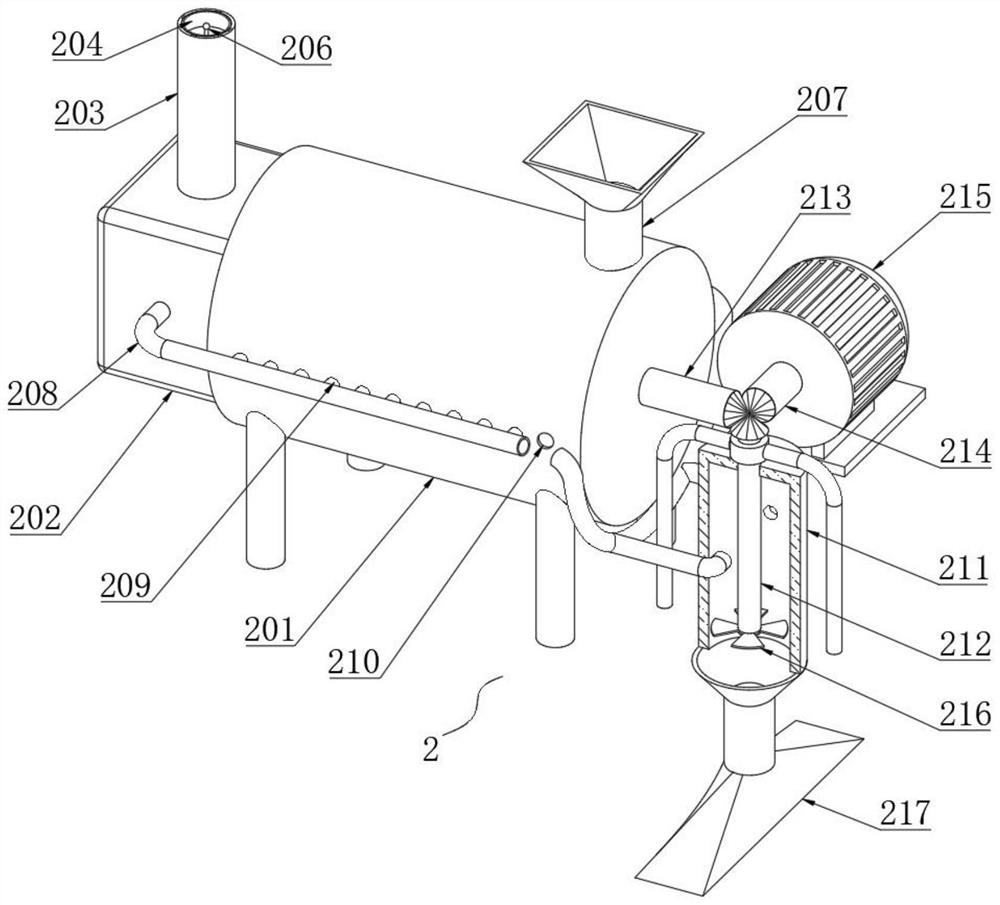

[0050] Such as Figure 1-8 As shown, the present invention provides a technical solution, a spraying device for surface coatings of road construction bridges, including a housing 1, in order to avoid cooling and solidification of materials during storage, a stirring and drying mechanism 2 is installed inside the housing 1;

[0051] Stirring and drying mechanism 2 includes material storage box 201, electric heating box 202, air inlet pipe 203, filter box 204, sealing cover 205, handle 206, feed pipe 207, ventilation pipe 208, through pipe 209, heat conducting sheet 210, fixed Pipe 211, connecting shaft 212, stirring shaft 213, rotating shaft 214, rotating motor 215, fan blade 216, blowing cover 217 and dustproof cover 218;

[0052] The middle part of the inner side of the shell 1 is equipped with a material storage box 201, and the outer edge of the material storage box 201 is equipped with a material feeding and brushing mechanism 5, and one end of the material storage box 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com