High-barrier flame-retardant composite sealing sleeve and preparation device thereof

A flame-retardant composite and preparation device technology, which is applied in the field of sealing sleeves, can solve problems affecting the storage of stored items, damage to stored items, and inability to block external radiation, so as to improve economic benefits, use safety and convenience, and reduce the probability of workpiece burns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

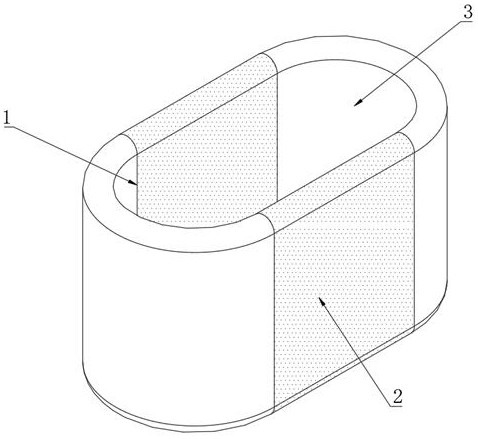

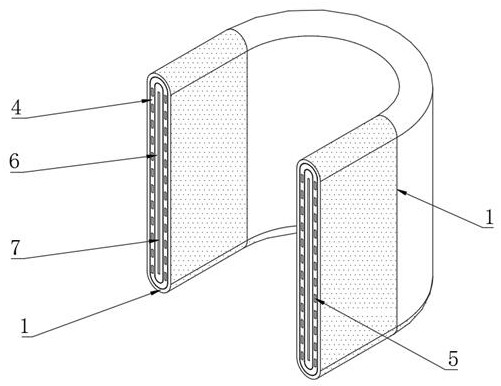

[0055] Example 1: as Figure 1-2 As shown, the present invention provides a technical solution, a high-barrier flame-retardant composite storage sleeve, including a flame-retardant outer layer 1, and the outside of the flame-retardant outer layer 1 is symmetrically embedded with a frosted outer layer 2, and the outer side of the flame-retardant outer layer 1 corresponds to A heat-resistant rubber outer layer 3 is symmetrically embedded on both sides of the frosted outer layer 2, and a barrier inner layer 4 is bonded to the inner side of the flame-retardant outer layer 1, and a barrier strip 5 is evenly embedded in the inside of the barrier inner layer 4. The inner side of the layer 4 is bonded with a soft inner layer 6, and the inner side of the soft inner layer 6 is embedded with an embedded barrier plate 7. The interval between two adjacent barrier strips 5 is 5 mm, and the thickness of the embedded barrier plate 7 is 3 mm. , increasing the barrier capacity of the barrier in...

Embodiment 2

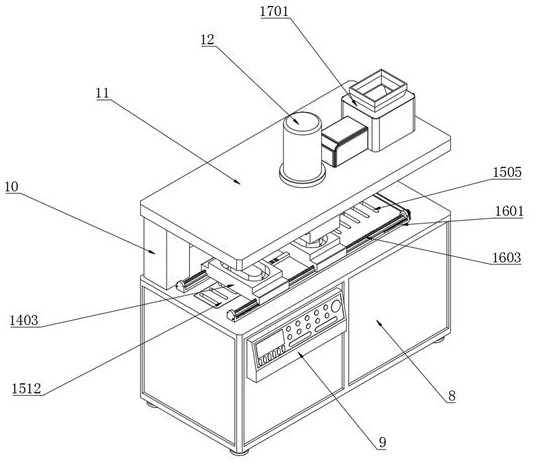

[0056] Example 2: as Figure 3-15 As shown, the present invention provides a technical solution, a high-barrier flame-retardant composite sealing sleeve preparation device, including an injection molding body 8, a control switch 9 is installed at one end of the injection molding body 8, and a connecting column 10 is symmetrically connected to the top of the injection molding body 8. A top plate 11 is installed on the top of the column 10, a hydraulic telescopic rod 12 is connected to the top of the top plate 11, and an upper mold 13 is installed on the bottom end of the hydraulic telescopic rod 12 through the top plate 11;

[0057] The top of the injection molding machine body 8 is slidably equipped with a dual mold ejector cooling mechanism 14, which includes a first mold 1401, a connecting warehouse 1402, a second mold 1403, a partition plate 1404, an air inlet 1405, and an air delivery pump. 1406, cavity 1407, top groove 1408, fixed column 1409, telescopic column 1410, floa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com