Glue removing and cleaning equipment for producing sanitary towels

A technology for cleaning equipment and sanitary napkins, applied in cleaning devices, lighting and heating equipment, applications, etc., can solve problems such as incomplete scraping, water splashes, blade damage, etc., to improve the cleaning effect of scraping and improve the falling effect, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

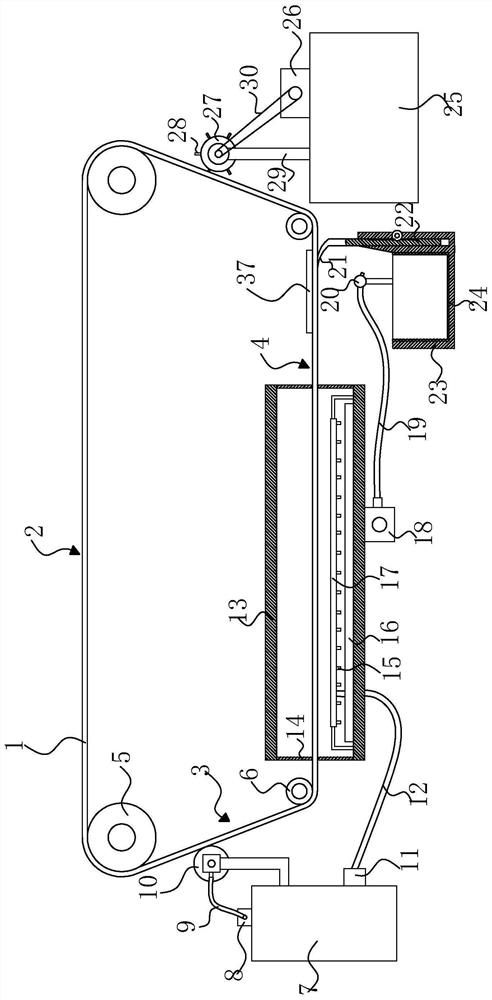

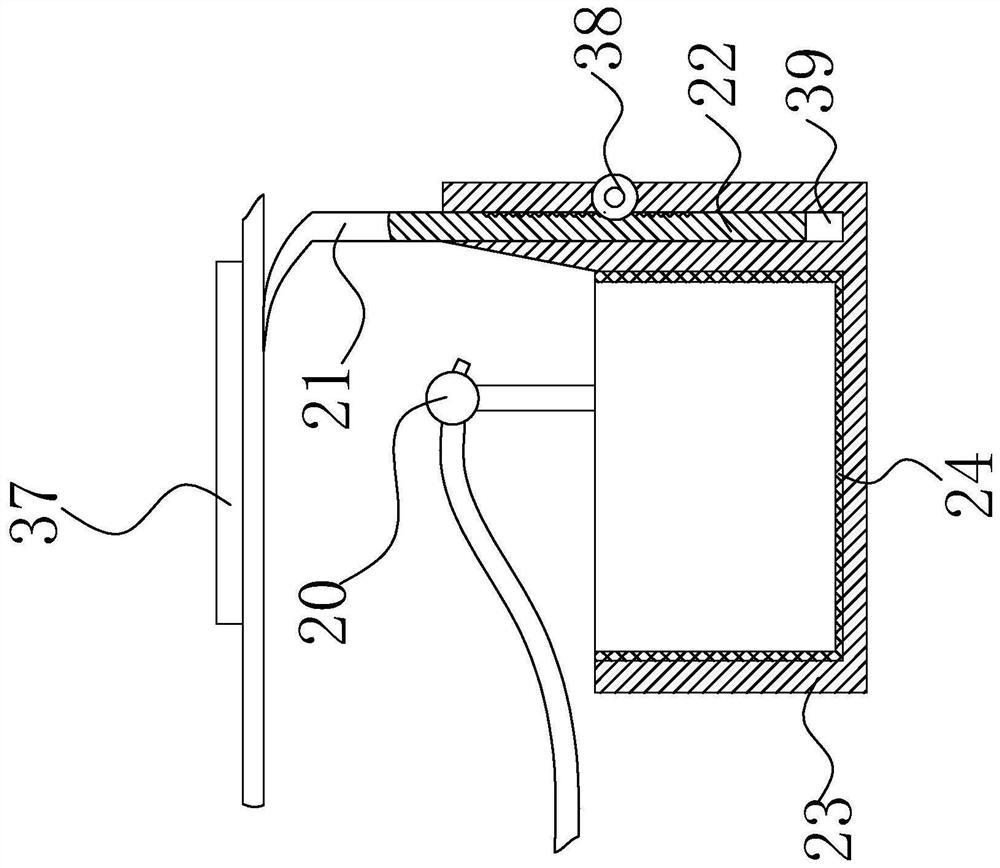

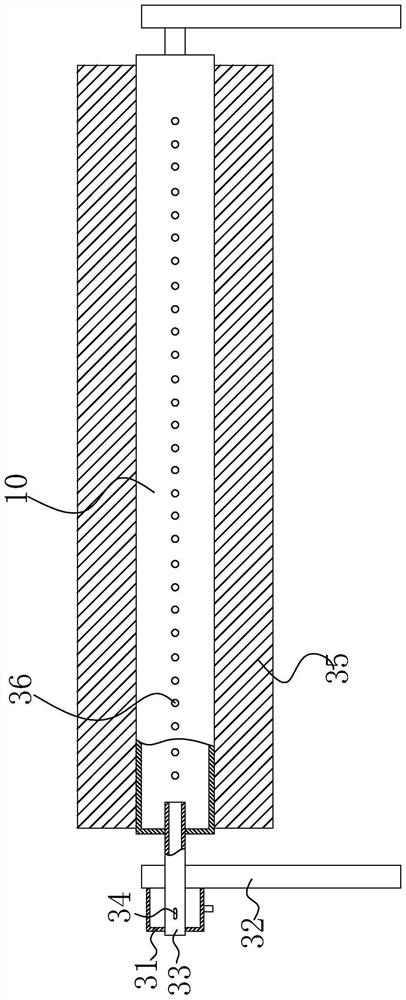

[0029] refer to figure 1 , the embodiment of the present invention discloses a degumming and cleaning device for producing sanitary napkins, including two main rollers 5 located above and two auxiliary rollers 6 located below, and a conveyor belt is wound on the main rollers 5 and auxiliary rollers 6 1. The conveyor belt 1 is in an inverted trapezoid shape as a whole. The section of the conveyor belt 1 between the two main rollers 5 is the gluing section 2. The sanitary napkin cloth is glued on the gluing section 2. The conveyor belt 1 is located on the two auxiliary rollers 6 The section between is the glue removal section 4, and the oblique side section 3 connected to both sides of the glue application section 2 and the glue removal section 4, wherein the oblique side section 3 on the left side is provided with a cleaning component, and the side section on the right side is provided with a cleaning assembly. The oblique side section 3 is equipped with a secondary scraping as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com