Flow-casting mold cleaning device

A technology for cleaning devices and molds, applied in the direction of coating, etc., can solve the problems of material cooling and solidification, manual cleaning, time-consuming and laborious, etc., and achieve the effect of simple operation and prevention of cooling and solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

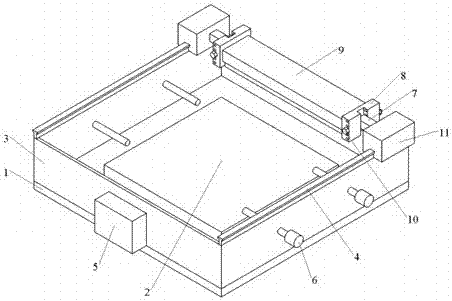

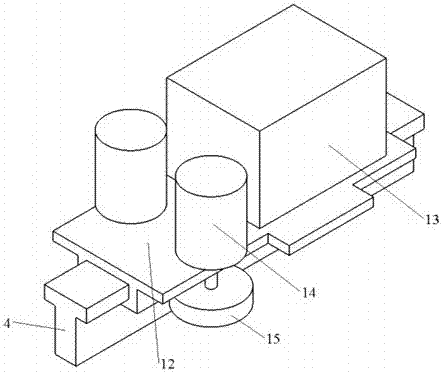

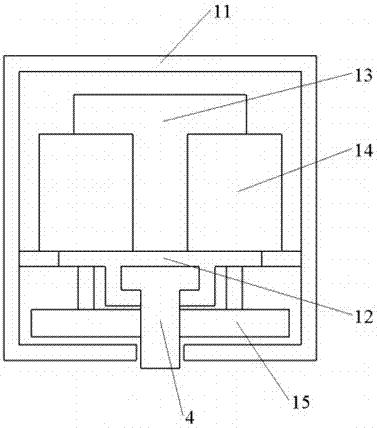

[0017] see Figure 1-Figure 3 , a casting mold cleaning device according to an embodiment of the present invention, comprising a base 1, a frame 3, a heating device 2, a control device 5, a fixing device 6, a guide rail 4, a power device, an adjusting device and a brush 9; The base 1 is provided with the frame 3 and the heating device 2; the control device 5 is provided on the outside of the frame 3; the fixing device 6 is provided on both sides of the frame 3; The guide rail 4 is arranged on both sides above the frame 3; the power device is provided on the guide rail 4; the power device includes a driver 13, a slide block 12, a motor 14, a rubber wheel 15 and a casing 11; the adjustment device It includes an adjustment base 8, a bolt 10 and a connecting rod 7; the connecting rod 7 is connected to the housing 11; the connecting rod 7 is connected to the adjustment base 8 through the bolt 10; the adjustment base 8 and the The brush 9 is connected; the control device 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com