Side inserted agitator

A reduction box and bracket technology, applied in mixer accessories, mixers with rotating stirring devices, chemical instruments and methods, etc., can solve the problems of spindle leakage, mechanical seal damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

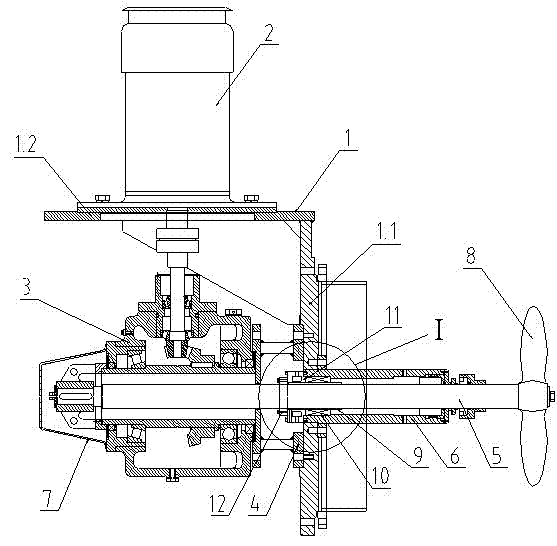

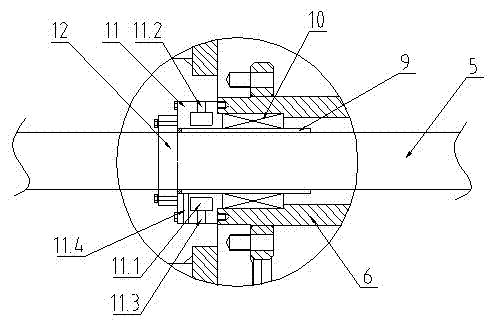

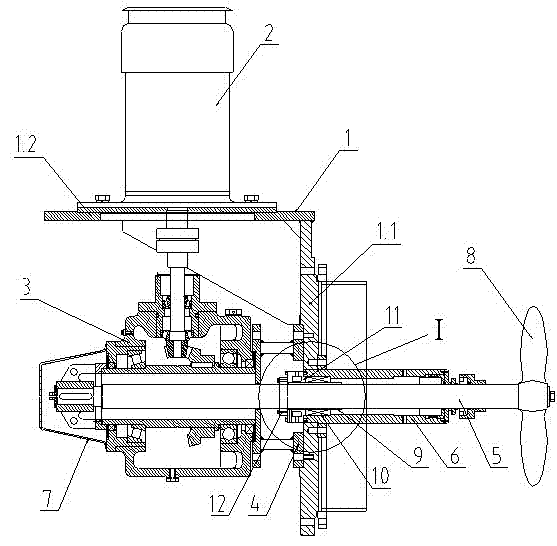

[0011] see Figure 1 ~ Figure 2 , the present invention relates to a laterally extending agitator, which includes a bracket 1, a motor 2, a reduction box 3, a main shaft 5 and an impeller 8, the bracket 1 includes a vertical plate 1.1 and a horizontal plate 1.2, the motor 2. It is fixedly installed on the horizontal plate 1.2. The outer side of the vertical plate 1.1 is fixedly provided with a fixed seat 4. The reduction box 3 is fixedly installed on the fixed seat 4. The outer side of the reduction box 3 is provided with a protective cover 7. The motor 2 The output end is connected to the input end of the reduction box 3 through a coupling, the output end of the reduction box 3 is connected to one end of the main shaft 5 through a transmission sleeve, and the impeller 8 is fixedly arranged on the other end of the main shaft 5, The main shaft 5 is sequentially fitted with an outrigger 6 and a shaft sleeve 9 from the inside to the outside, one end of the outrigger 6 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com