Grouting equipment for manufacturing of plastic products

A plastic product and grouting technology, which is applied in the field of plastic product production equipment, can solve the problems of slurry leakage, too much or too little slurry, and lack of moving components, etc., to achieve safe and convenient use, increase conveying speed, and scientific and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

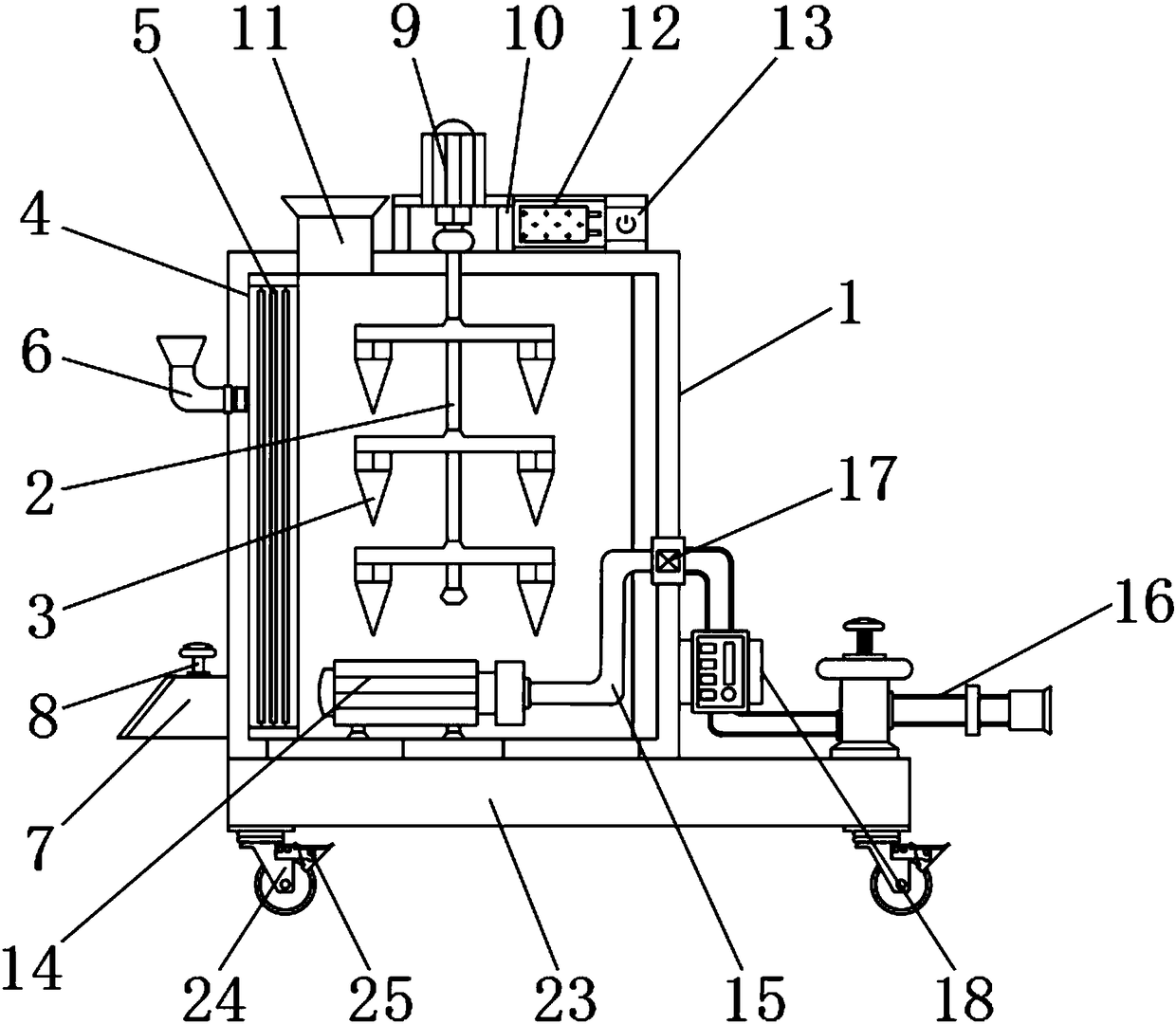

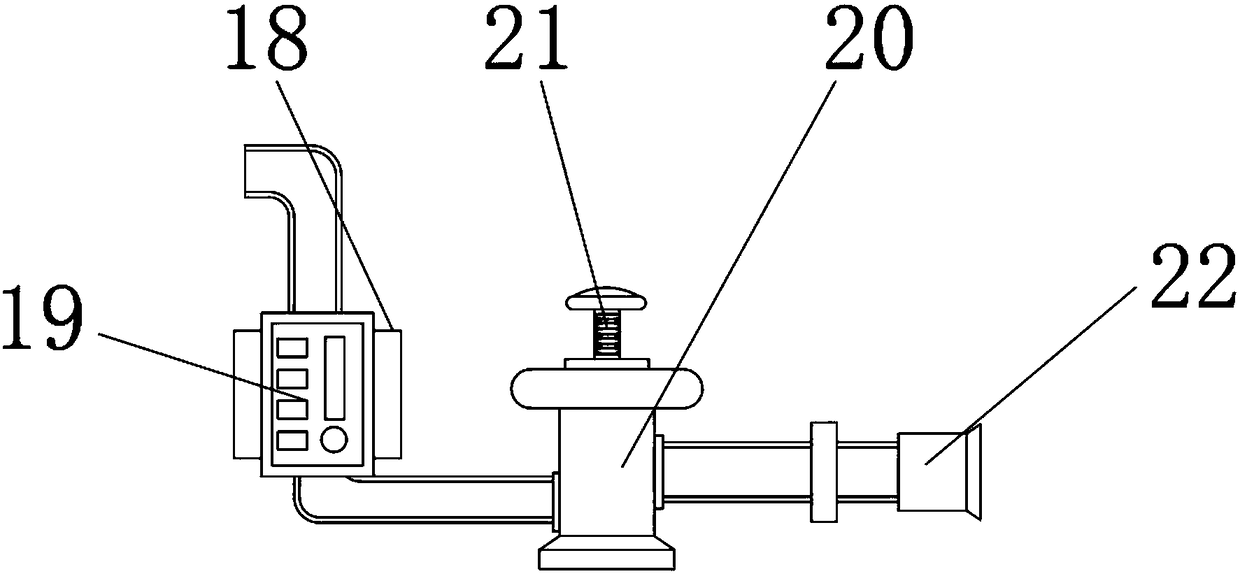

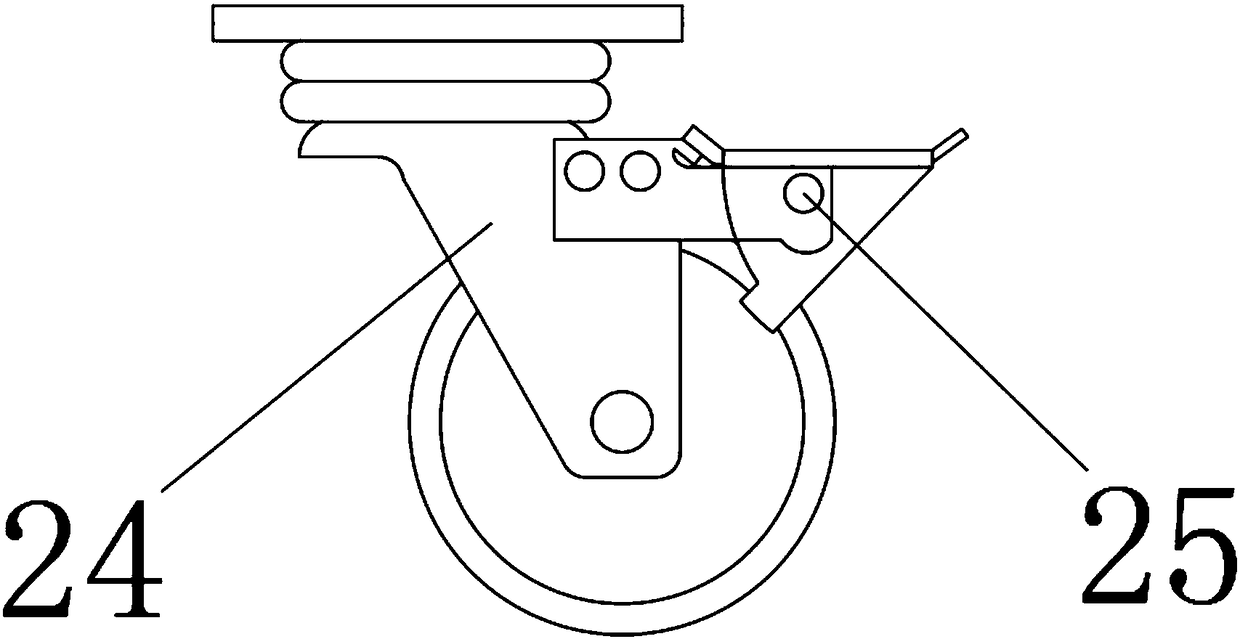

[0017] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a grouting equipment for the production of plastic products, including a modulation body 1, a rotating shaft 2, a mixing paddle 3, an electromagnetic heating plate 4, an electric heating wire 5, and a material addition port 6. Waste outlet 7, switch valve 8, motor 9, motor bracket 10, feed inlet 11, power supply 12, control switch 13, slurry pump 14, slurry delivery pipeline 15, insulation layer 16, sealant sleeve 17, grouting Device 18, electromagnetic batching device 19, press opening and closing valve 20, press knob 21, grouting port 22, fixed bottom plate 23, moving wheel 24 and brake 25, the middle part of the inner side of the modulation body 1 is movable and installed with a rotating shaft 2, and the rotating shaft 2 rotates on both sides A mixing paddle 3 is connected, an electromagnetic heating plate 4 is fixedly installed at one end of the inside of the modulation body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com