A kind of sucrose-6-ester production device and production method

A production device and technology for sucrose, applied in separation methods, sugar derivatives, sugar derivatives, etc., can solve the problems of reduced production efficiency and increased by-products, and achieve high production efficiency, no by-products, and improved evaporation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

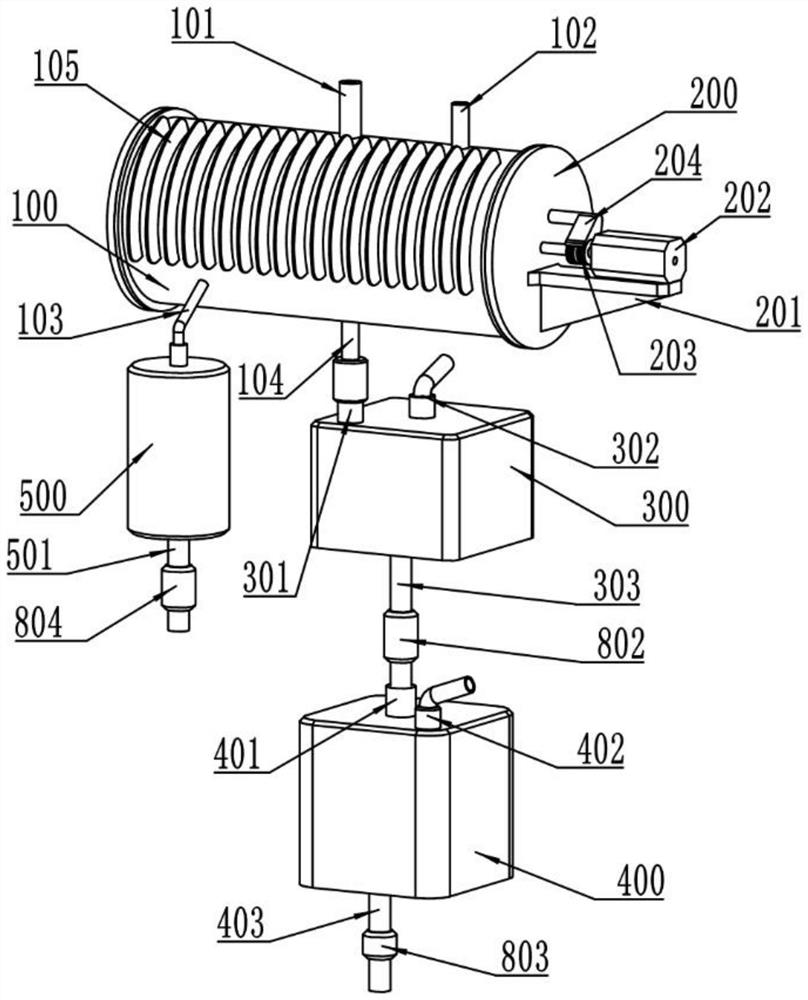

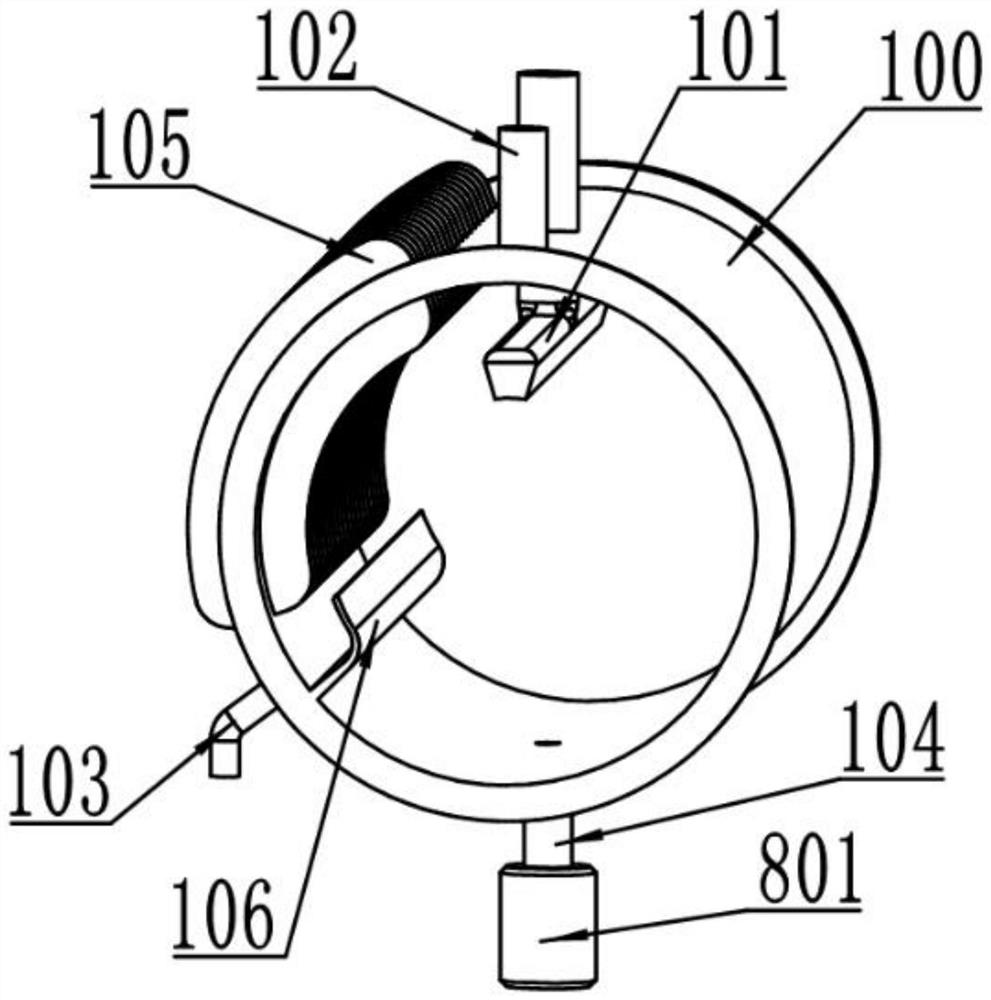

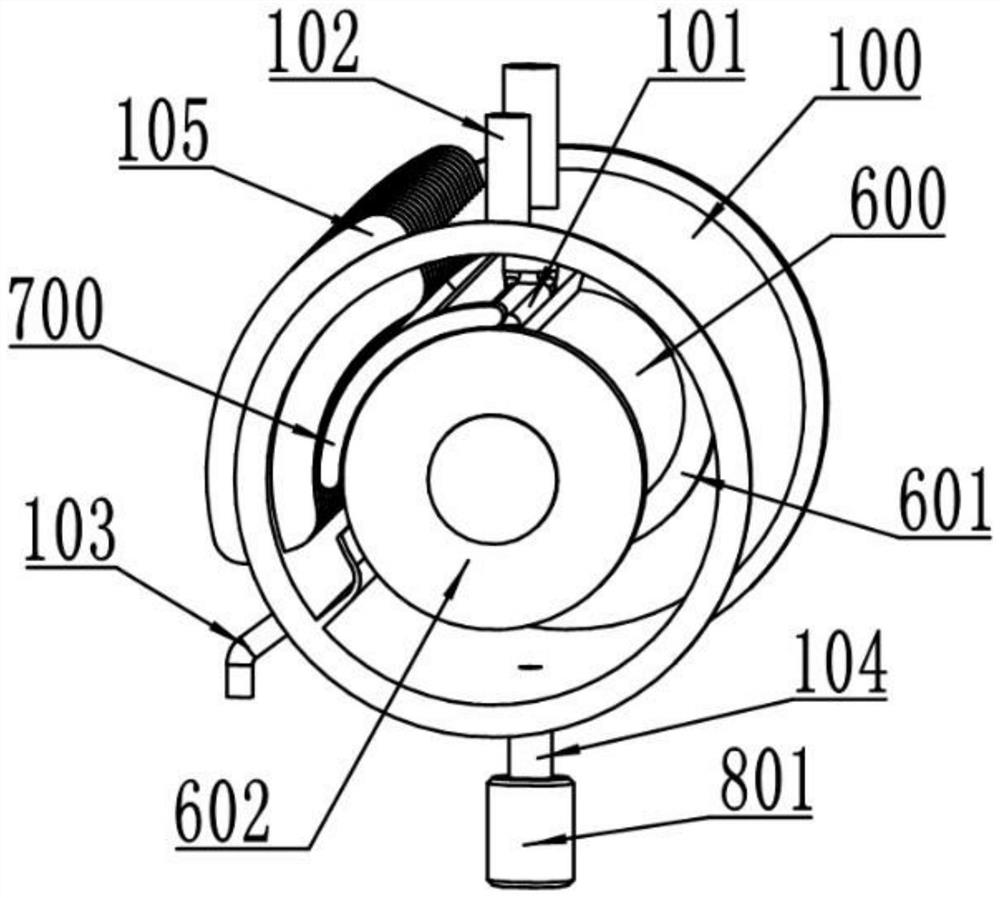

[0037] refer to Figure 1-4 , a sucrose-6-ester production device, comprising: a distillation tank 100, a right side cover 200, a storage tank 300, a reaction tank 400, a cooling water collection tank 500, a heating column 600, and a heating scraper group 700.

[0038] refer to Figure 1-2 , the retort 100 is made of stainless steel, and the retort 100 is a horizontal cylindrical body whose right end is open. The top of the retort 100 is provided with a feed pipe 101 and a vacuum pump connection port 102, the feed pipe 101 is in an inverted T shape, the lower end of the feed pipe 101 is located in the retort 100, and a water outlet pipe 103 and a discharge pipe are arranged below the retort 100 - 104 , a plurality of condensation plates 105 are arranged on the side wall of the distillation tank 100 , and the tail ends of the condensation plates 105 extend to the inner cavity of the distillation tank 100 . The inner cavity of the distillation tank 100 is located below the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com