Hydrogen for polycrystalline silicon production, impurity removal method and system, and polycrystalline silicon production method and system

A polysilicon and hydrogen technology is applied in the polysilicon production method and system, the impurity removal method and system, and the field of hydrogen for polysilicon production, which can solve the problems of affecting quality and limited cooling water removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

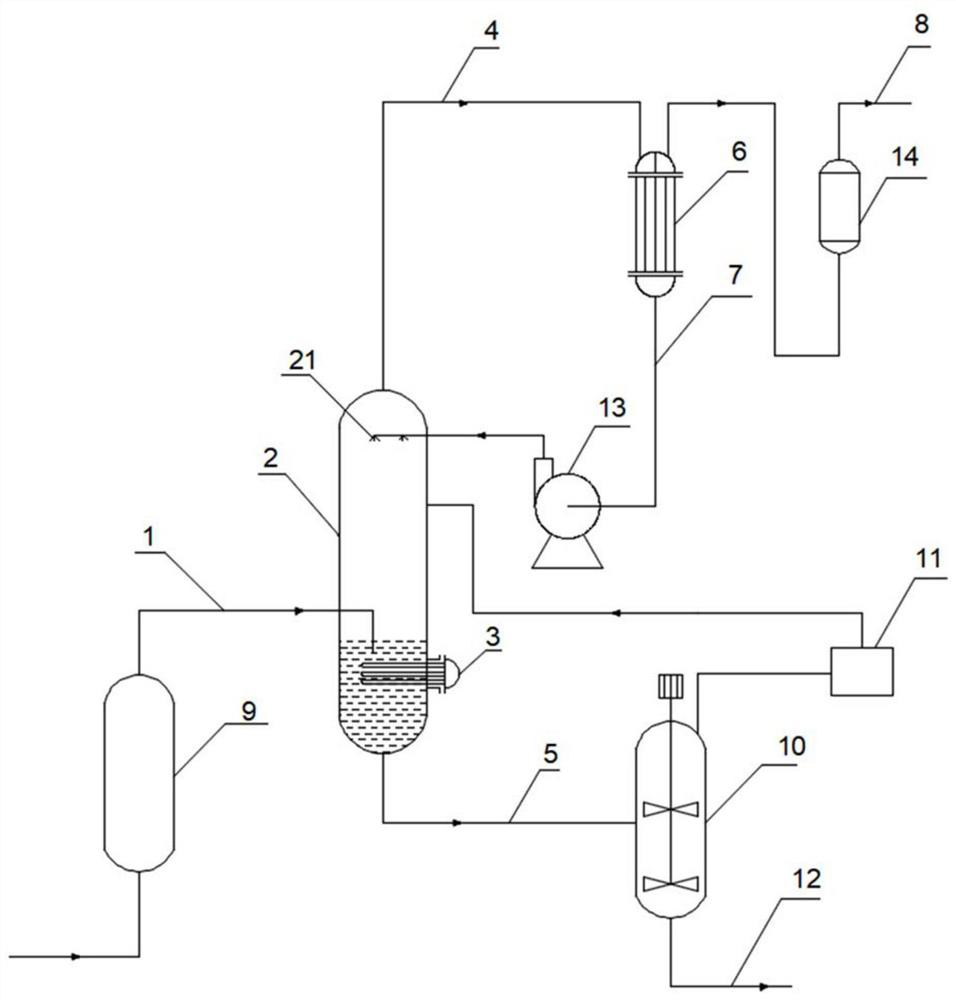

[0054] The present embodiment provides a polycrystalline silicon production method of hydrogen impurity, comprising the steps of:

[0055] The polysilicon production of trichlorosilane with hydrogen gas into boiling, so that the internal trap the hydrogen reacts with silicon trichloride, trichlorosilane from escaping in vapor phase under the shower and atomized trichloro hydrogen silicon contact, so the remaining water vapor within the reaction with hydrogen silicon trichloride, in addition to water vapor obtained;

[0056] The water vapor is then condensed in addition to the vaporized hydrogen trichloro therein liquefied silicon, polysilicon production obtained with the hydrogen impurity.

[0057] Hydrogen impurity polysilicon production by using the intermediate product as a desiccant trichlorosilane, trichlorosilane is reacted with hydrogen in the water to form a precipitate, HCl and hydrogen, trichlorosilane and small amounts of HCl gas is introduced vaporized after drying pol...

Embodiment 2

[0070] The present embodiment provides a hydrogen production using polycrystalline silicon produced by the method of Example 1.

Embodiment 3

[0072] The present embodiment provides a method for producing polycrystalline silicon, comprising the steps of:

[0073] To purify polysilicon production method of Example 1 of the embodiment obtained with hydrogen chloride for the synthesis,

[0074] The reaction of silicon powder with hydrogen chloride to trichlorosilane synthesis,

[0075] The trichlorosilane reduced to obtain polycrystalline silicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com