Water project silt cleaning equipment having functions of digging and spading

A water conservancy engineering and functional technology, which can be used in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., and can solve problems such as reducing the activity of heavy metals, cleaning, and inability to use extraction methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

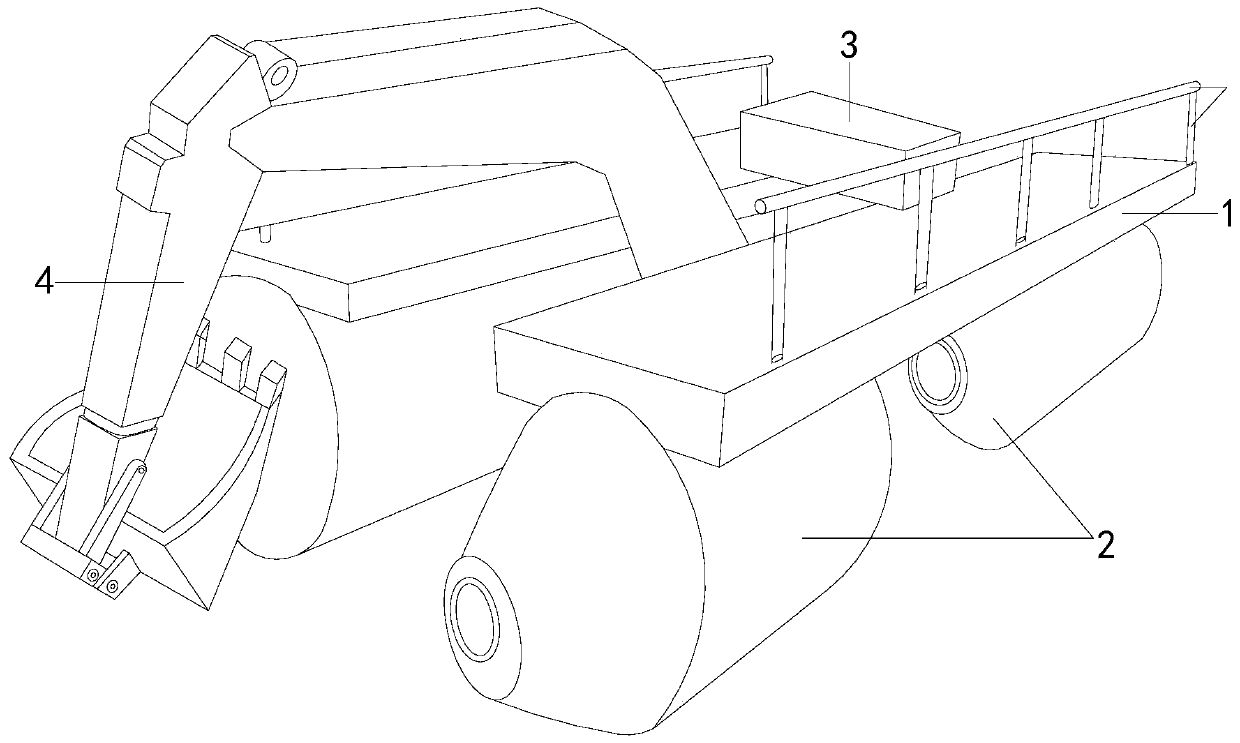

[0020] see figure 1 , the present invention provides a dredging equipment for water conservancy projects with the function of digging and shoveling. 2. The power box 3 is located at the center point of the surface of the launching frame 1. The launching frame 1 and the dredging mechanism 4 are connected to each other. The launching frame 1 is the basic structure of the equipment, mainly relying on the pair of railings set by two rectangular metal plates. The operator forms a lateral protection, prevents it from falling when working on the water surface, and can form a supporting force for it. It is also the shell connection carrier structure of other components, which is used to connect other components around the structure and form equipment The basis of operation, the buoy 2 is made of high-strength non-submersible plastic material, and there are four of them in total. Two pairs are set as a group and are located on the bottom side of the launching frame 1 and correspond to...

Embodiment 2

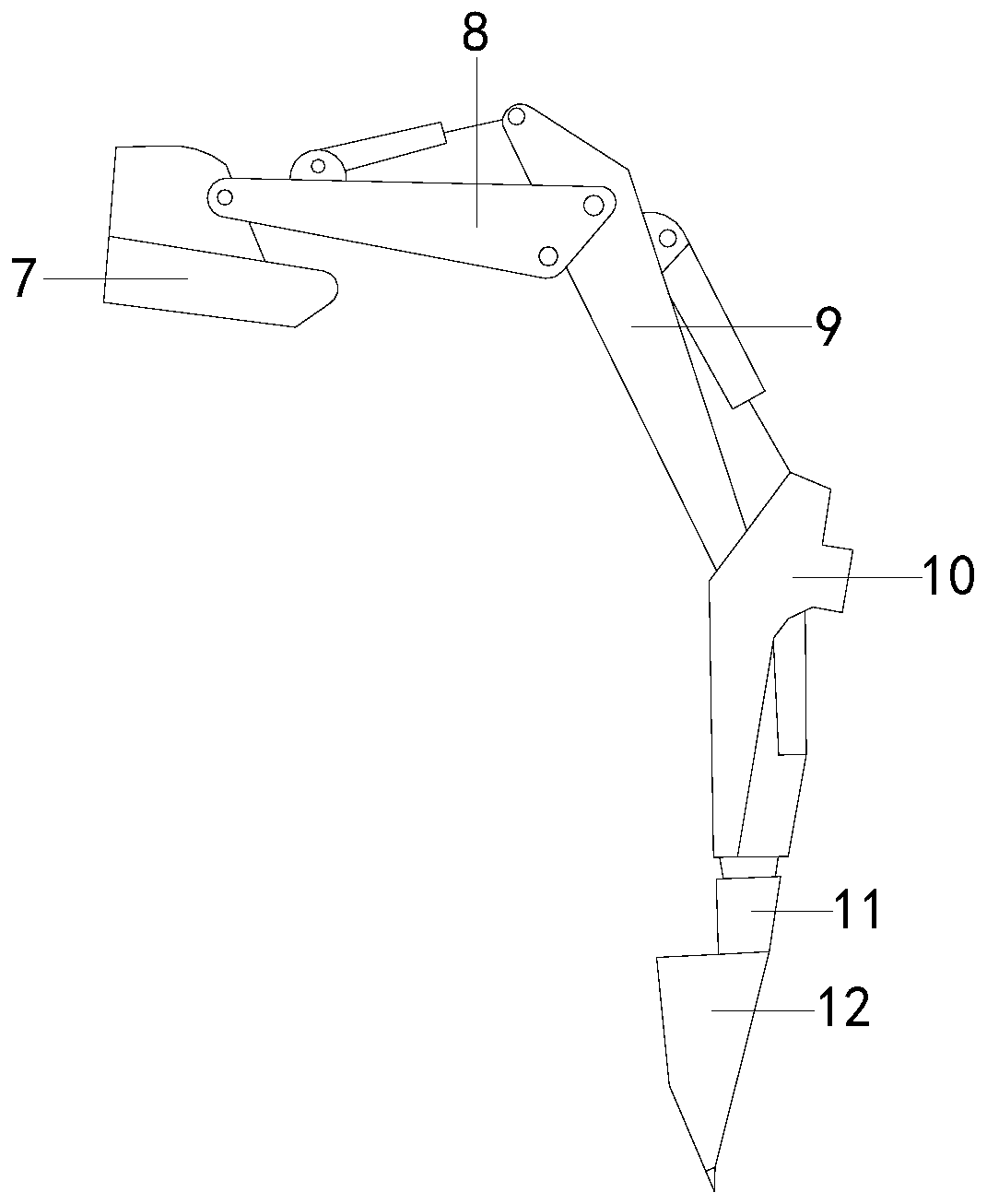

[0026] The description of the second embodiment drawn in conjunction with the first embodiment, combined with Figure 4 and Figure 5 , the shaft sleeve 20 is connected with a stretching shaft 21 through it, and the stretching shaft 21 is connected to the drainage bucket 24 through the bracket arm 22, and the top of the drainage bucket 24 is provided with a reflux cover 23, and the deflection collar 27 is connected to Bucket main body 28, bucket main body 28 is respectively provided with drainage bar 29 and seepage plate 30 at side position and bottom position, and shovel head 31 is positioned at the front end of bucket main body 28, when dredging bucket device 12 goes deep into water, pulls The extension shaft 21 depends on the structural expansion of the bracket arm 22 to change the distance from the drainage bucket 24, and controls the rotation angle of the drainage bucket 24. The difference in deflection angle can better fit the underwater mud , so that the most efficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com