Oil drilling cutting dryer

An oil drilling and drying machine technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of wasting resources, polluting the environment, unreasonable structural design of solid-liquid separation equipment, etc., and reducing environmental pollution. and drilling fluid waste, simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

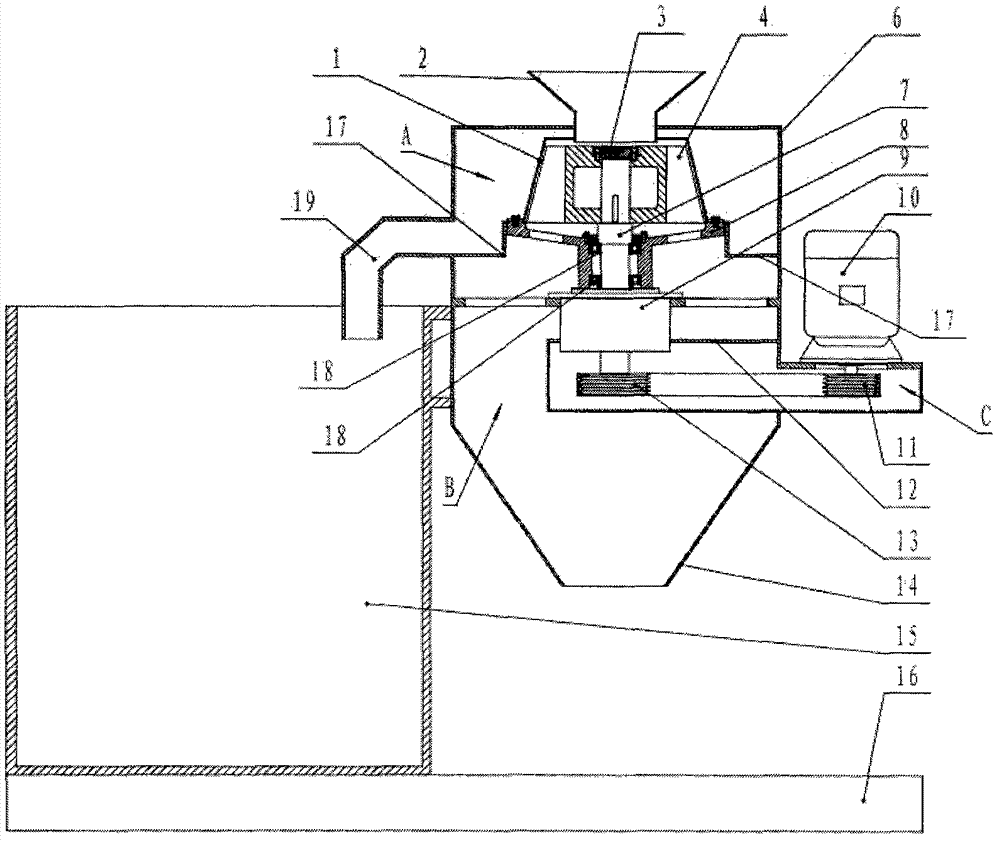

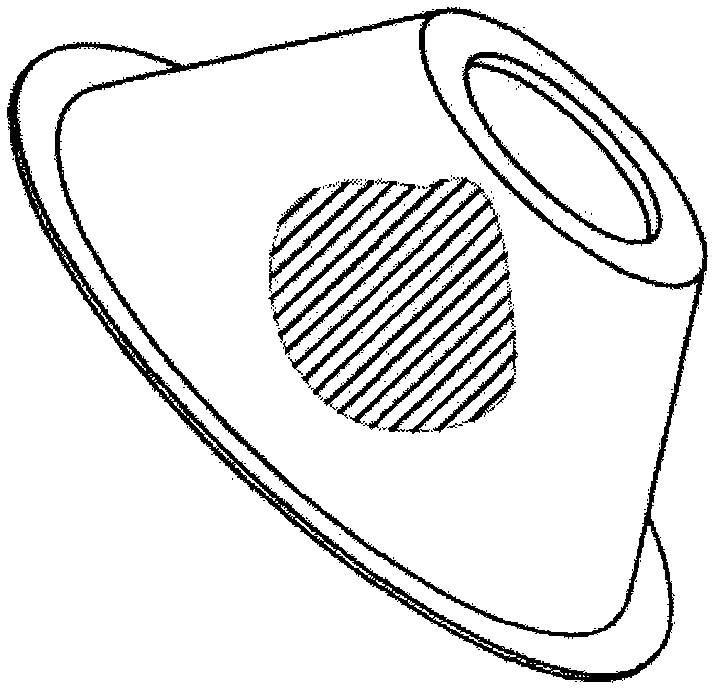

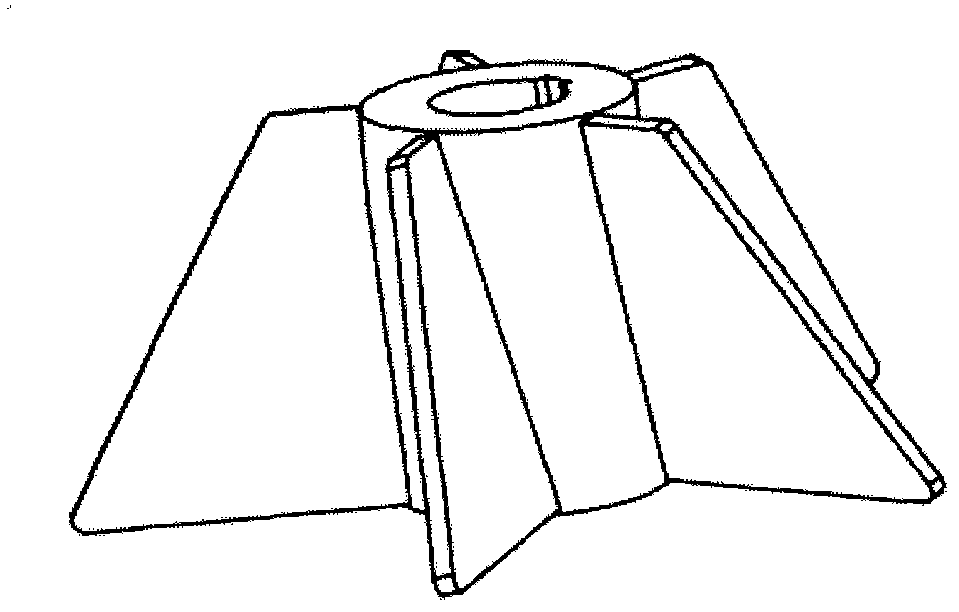

[0013] as attached figure 1 In the illustrated embodiment, the present invention is provided with: a conical screen 1, a feeding funnel 2, a scraper platen 3, a scraper 4, a dryer shell 6, a central shaft 7, a rotating arm 8, a transmission 9, and a motor 10 , first pulley 11, partition 12, second pulley 13, discharge funnel 14, storage tank 15, base 16, partition 17, bearing 18, drain pipe 19, conical screen 1 (see attached figure 2 ) is fixed on the rotating arm 8 that rotates with it, the shaft of the rotating arm 8 is a hollow shaft and a central shaft 7 is housed in its shaft hole, the central shaft 7 is supported by a bearing 18 and rotates relative to the rotating arm 8, the central shaft 7 is equipped with Scraper 4, scraper 4 (see attached image 3 ) is formed with 5 scrapers, the rotating arm 8 and the central shaft 7 are connected and driven by the transmission 9, the transmission 9 is fixed on the shell 6 of the drying machine, the motor 10 is driven by the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com