Gas-liquid coalescence filter element and application and filtering device containing gas-liquid coalescence filter element

A technology of coalescing and filter elements, which is applied in the field of multiphase flow separation, can solve the problems of poor performance of pressure drop, and achieve the effect of good ability to intercept droplets, promote discharge, and improve filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

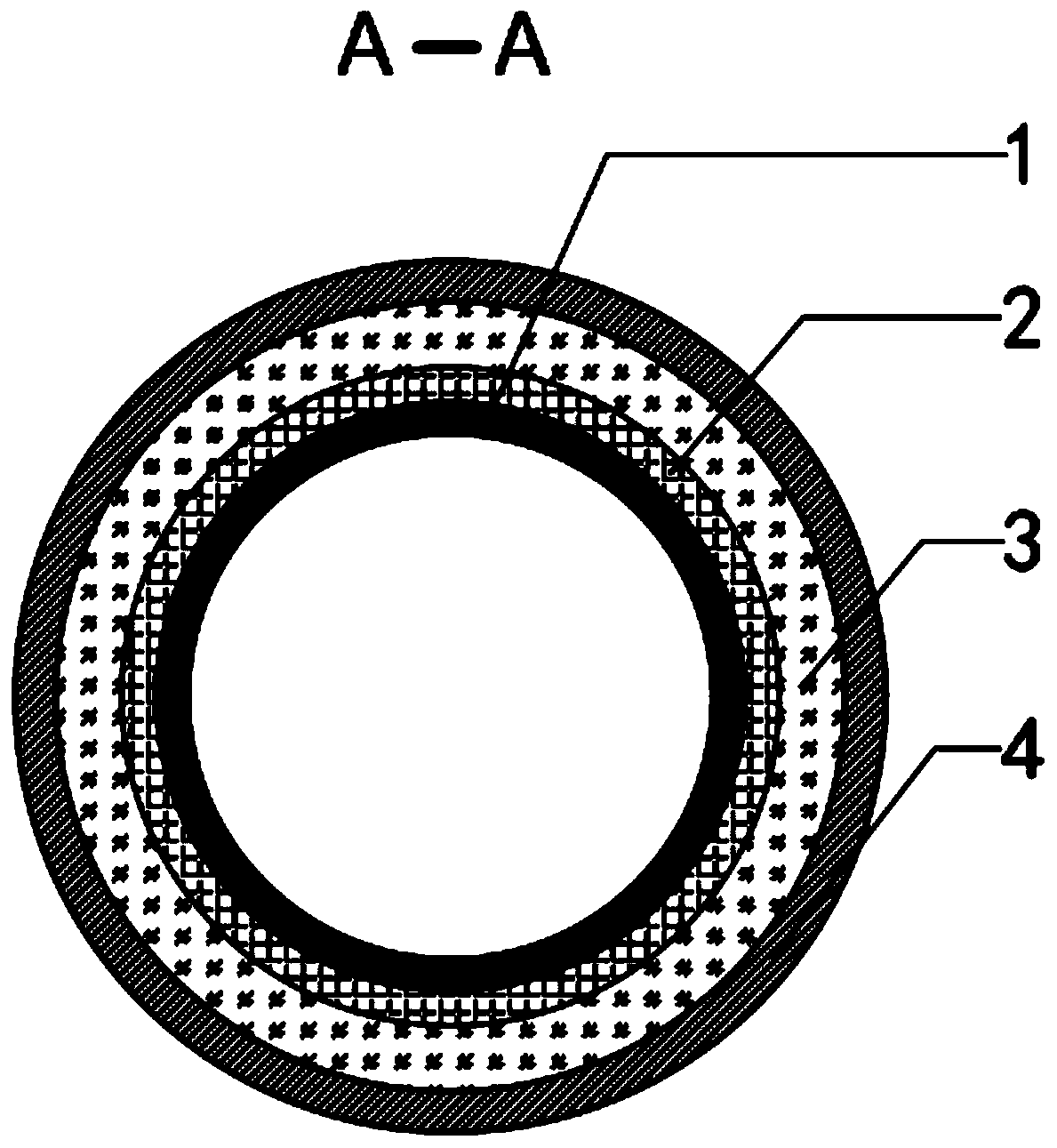

[0065] This embodiment provides a gas-liquid coalescing filter with a structure such as Figure 2A and Figure 2B As shown, the filtering device includes a filter frame 1 and a filter core wound on the surface of the supporting frame 1 . Among them, the special-shaped fiber pre-separation layer 2 is wound on the surface of the filter skeleton 1, and the number of winding turns is 1; the special-shaped fiber coalescence layer 3 continues to wind along the special-shaped fiber pre-separation layer 2, and the number of winding turns is 4 turns; the special-shaped fiber discharge Layer 4 continues to wind along the special-shaped fiber coalescing layer 3, and the number of winding turns is 1 turn.

[0066] Wherein, the average pore diameter of the special-shaped fiber pre-separation layer 2 is 10 μm, the thickness is 1.5 mm, and the fiber shape of the special-shaped fiber used is cross. The diameter (diameter of circumscribed circle) of the shaped fiber used was 15 μm. The pre-...

Embodiment 2

[0076] In Example 1, the shapes of the shaped fibers of the pre-separation layer, the coalescence layer, and the drainage layer are trilobal, and the other parameters remain unchanged. The experimental results showed that the pressure drop decreased by 10%, and the cumulative efficiency near the most easily penetrated particle size increased from 99.48% to 99.82%.

Embodiment 3

[0078] In Example 1, the coalescing layer with an average pore diameter of 3 μm is selected, and the other parameters remain unchanged. The experimental results showed that the pressure drop decreased by 15%, and the cumulative efficiency near the most easily penetrated particle size changed from 99.48% to 99.85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com