Method and apparatus for the integrated cleaning of a paper-pulp processing plant

a technology of integrated cleaning and processing plant, which is applied in the direction of papermaking, fat/resin/pitch/waxe removal in pulp, textiles and paper, etc. it can solve the problems of affecting the production process, and affecting the quality of paper produced, so as to achieve the effect of convenient disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

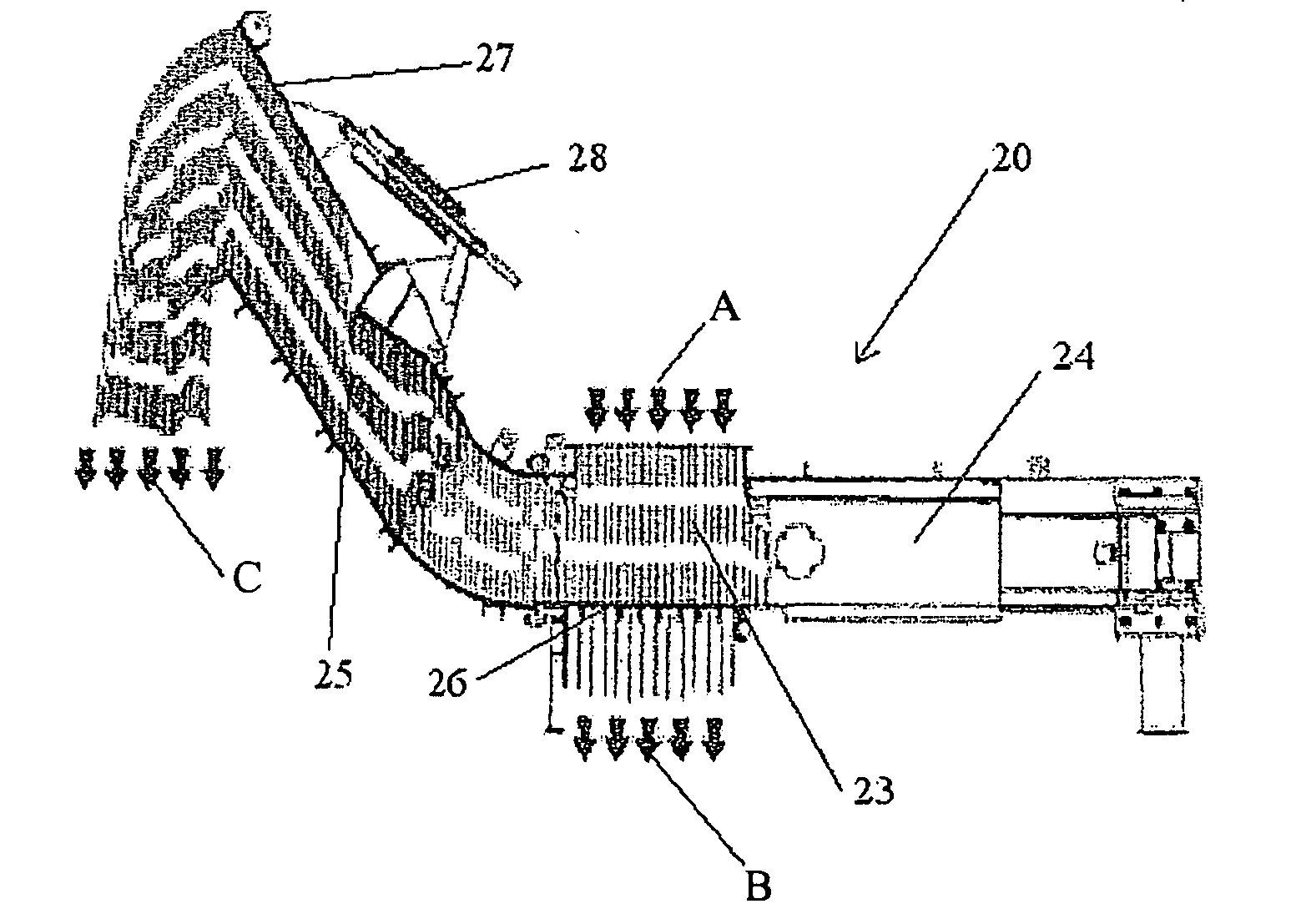

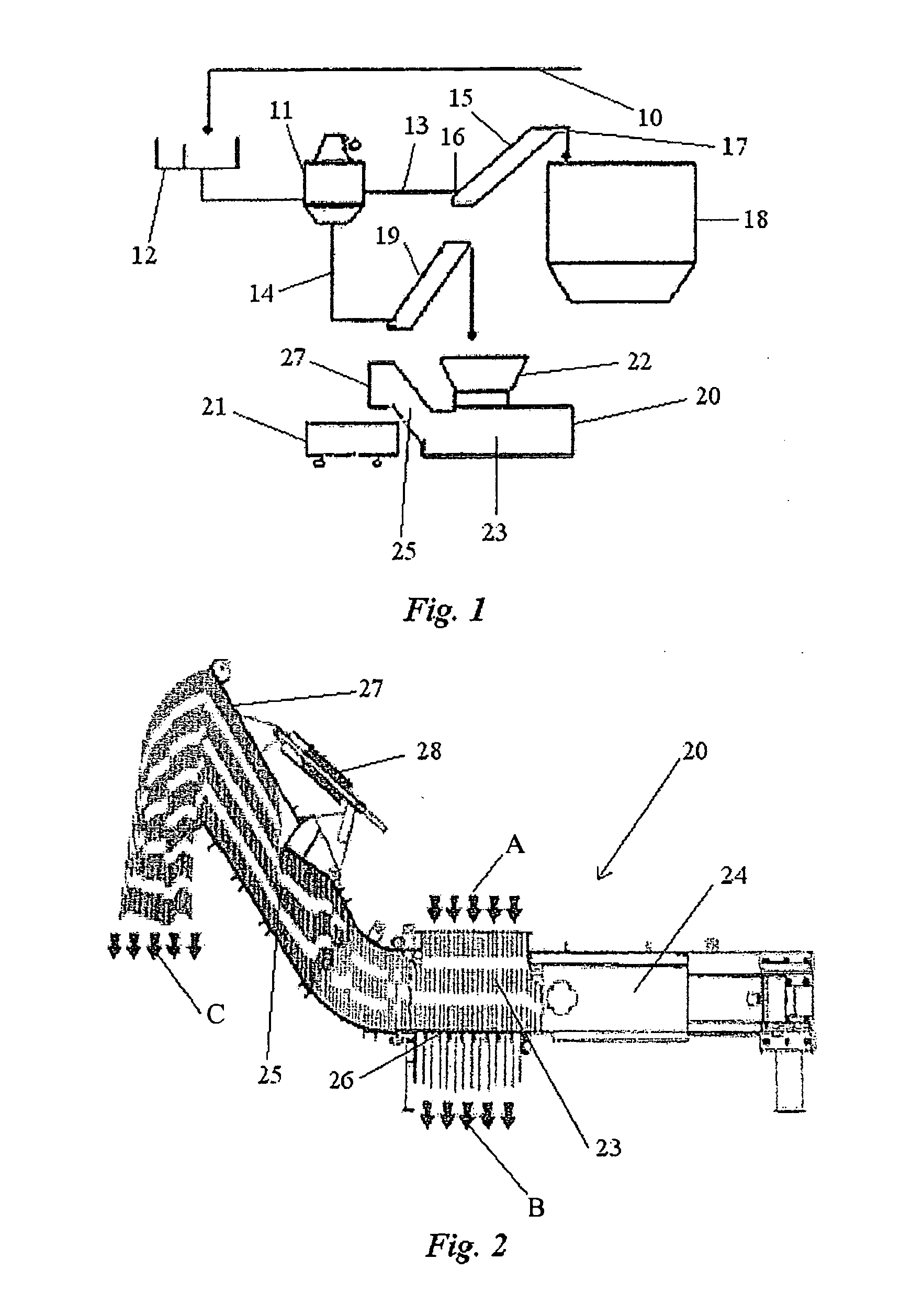

[0016]In the present invention rejected flow from the final high density cleaner in a conventional pulp processing plant is subjected to a cleaning process prior to its reintroduction into stock provided at the commencement of the process. A high density cleaner is a feed stock (pulp) cleaner that removes undesired high density contaminants from the pulp. The cleaning process is, therefore, integrated into the pulp processing process as a whole.

[0017]Preferably, the contaminants in the separator are screened using a screen hole size of approximately 2.5 mm. This ensures that colloidal pollutants are screened out of the liquid which is recovered from the separator prior to its return to the stock.

[0018]According to a second aspect of the present invention there is provided a paper-pulp processing plant including one or more high density cleaners and incorporating apparatus for the integrated cleaning of same, the apparatus comprising:

[0019]a screening centrifugal separator set up to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com