Mechanical mixing stirrer

A mechanical mixing and agitator technology, applied in the direction of mixers, mixer accessories, mixers with rotating agitation devices, etc., can solve the problems of complex design and manufacturing, many consumables, and large energy consumption for mixing, and achieve low maintenance costs. Create flexible, power-efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

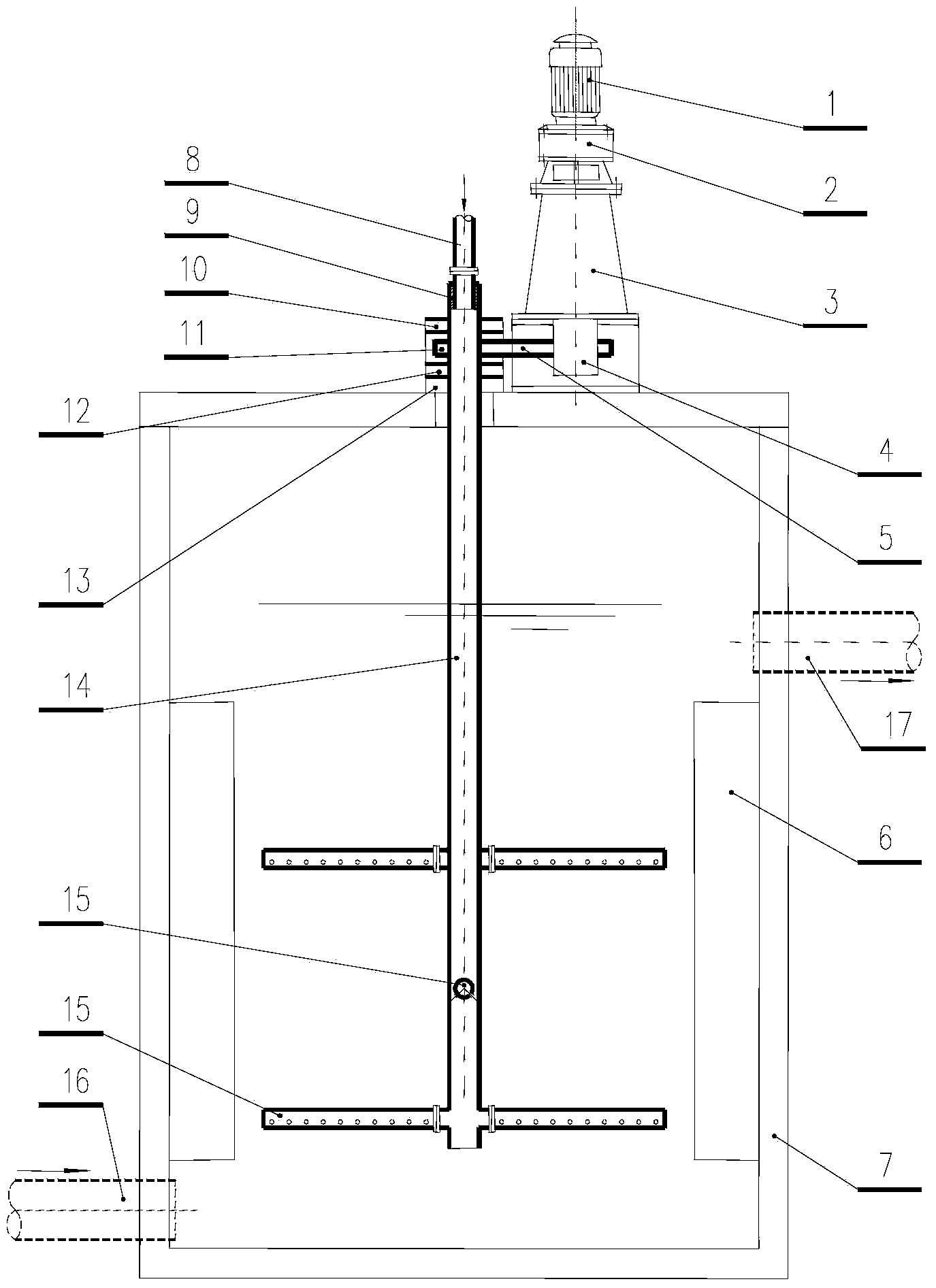

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] The mechanical mixing agitator of the present invention, the agitator is arranged in the mixing tank, is characterized in that: the agitator includes a driving mechanism, the agitating shaft driven by the driving mechanism through the transmission mechanism, wherein the agitating shaft is a hollow structure, The stirring shaft is connected with the medicine feeding pipe, and several strip-shaped porous pipes are interposed on the stirring shaft, and the stirring shaft is connected with the porous pipe.

[0018] Such as figure 1 As shown, the mechanical mixing agitator of this embodiment is arranged in a mixing tank, and the mixing tank is respectively provided with an inlet pipe 16 and an outlet pipe 17, and a deflector 6 is arranged in the mixing tank. Described agitator comprises driving mechanism, the stirring shaft 14 that described driving mechanism drives...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com