Process of preparing tubular porous membrane with high permeating flux

A porous membrane, high-permeability technology, applied in the field of membrane separation, to achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

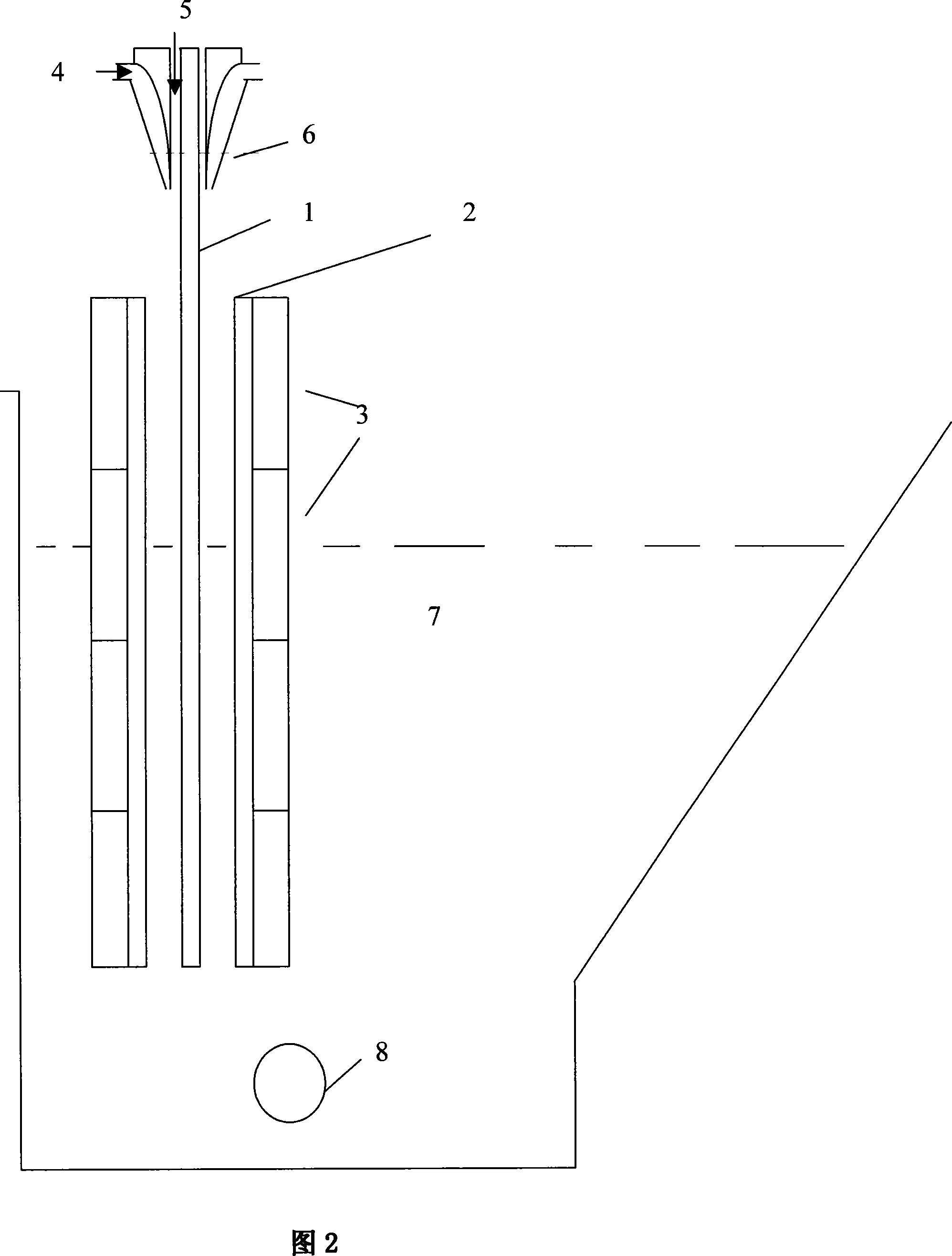

[0049] Example 1: Take 300ml of dimethylacetamide (DMAC) and place them in 5 batching tanks, respectively add 15.0g of polyvinylpyrrolidone (PVP) to them, and then weigh 240.0g, 140.0g, 90.0g, 60.0g in turn. g and 40.0 g iron tetroxide (Fe 3 O 4 ), and mixed with 60.0g of polysulfone (PS) respectively, and then added to the above-mentioned batching tank. The membrane is prepared according to the preparation method of the capillary membrane of the present invention. The pressure of the material kettle is 0.2MPa, the temperature of the film liquid is 30°C, the inner gel bath is distilled water at 25°C, the air gap without magnetic field is 10mm, the air gap with magnetic field is 340mm, air (humidity is 30%, temperature 25°C), the intensity of the magnetic field is 2100 Gauss, the length of the magnetic field action section in the outer gel bath is 1160mm, the outer gel bath is distilled water at 25°C, the traction speed is 15m / min, and the spun membrane is immersed in distill...

Embodiment 8

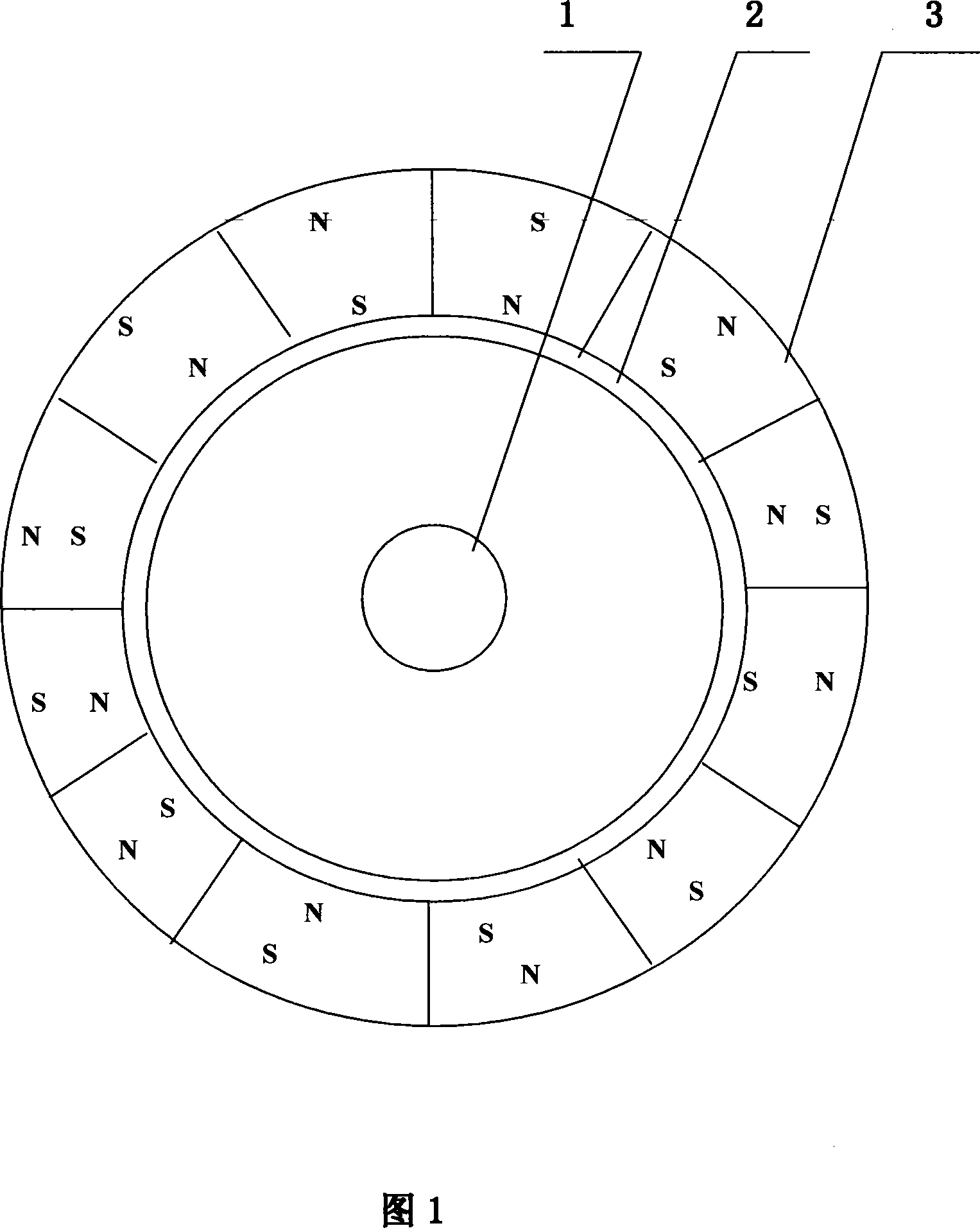

[0056] Take 150ml of dimethyl sulfoxide (DMSO) and place them in 5 batching tanks, respectively add 5.9g of polyvinylpyrrolidone (PVP) to them, and wait until they are fully dissolved; weigh 57.6g, 33.6g, 21.6g, 14.4g in turn g and 9.6 g iron tetroxide (Fe 3 O 4), and mixed with 14.4g of polyacrylonitrile (PAN), respectively, and then added to the above 5 batching tanks. Coat the inner wall of a porous alumina tube with a pore size of 20 μm, evaporate it in the air (humidity less than 50%, temperature 20°C) for about 5s, put it in an orthogonal magnetic field (magnetic field strength 1000 Gauss) and continue to evaporate for 25s, and then After the porous tube and the magnetic field action device were put into water for gelation for 15min, the porous tube was taken out and soaked in distilled water for 24 hours to obtain a magnetized film; the preparation method of the non-magnetized film used in the comparative study was as follows: in a porous alumina tube with a pore size ...

Embodiment 9

[0059] Example 9: take 120ml of dimethylacetamide (DMAC) and place it in a batching tank, add 13.0g polyethylene glycol to it, and wait for it to be fully dissolved; weigh 30.0g magnetic carbon nanotubes, 5.0g polysulfone and After mixing, 5.0 g of polyethersulfone was added to the above-mentioned batching tank, shaken quickly, dissolved uniformly by ultrasonic vibration at 55-60 °C, and then defoamed. Coat the outer wall of the porous polypropylene tube with a pore size of 10 μm, evaporate it in the air (humidity less than 60%, temperature is 22 °C) for 3s, put it in an orthogonal magnetic field (magnetic field strength 3500 Gauss) and continue to evaporate for 12s, and then the porous After the tube and the magnetic field action device were put into water for gelation for 15min, the porous tube was taken out and soaked in distilled water for 24 hours to obtain a magnetized film, and the pure water permeation flux was measured to be 1160 L.m -2 .h -1 (25°C, 0.1MPa); the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pure water permeation flux | aaaaa | aaaaa |

| Retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com