Artificial blood vessel silk fibroin and collagen blending pre-coagulation coating

A technology of artificial blood vessels and silk fibroin, which is applied in coatings, blood vessels, devices of human tubular structures, etc., can solve problems such as increased postoperative exudate, prolonged operation time, and complicated surgical operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Example 1: Method for Silk Fibroin and Collagen Extraction

[0025] Tussah silk in 0.5% (by weight) Na 2 CO 3 Boil in the solution for 1-1.5h to remove sericin (silk weight (g) and Na 2 CO 3 The solution volume (ml) ratio is between 1 / 80-1 / 67), using distilled water to repeatedly wash the silk stripped of sericin until it is completely clean. The clean sericin-free silk was placed in CaCl 2 / H 2 O / C 2 h 5 OH=1: 8: 2 (molar ratio) in the solvent (take off the silk weight (g) of sericin and H 2 O, C 2 h 5 OH volume (ml) and ratio between 1 / 10-1 / 15, then deduce CaCl 2 quality), dissolved at 70-80°C for 30-45 minutes, then cooled and put into a dialysis bag, dialyzed with distilled water for 3 days, filtered to obtain a high-purity silk fibroin aqueous solution, and then concentrated the silk fibroin solution by magnetic stirring to achieve the preparation of coating Layer material concentration (the temperature of the magnetic stirrer is controlled at 45-55°C). ...

example 2

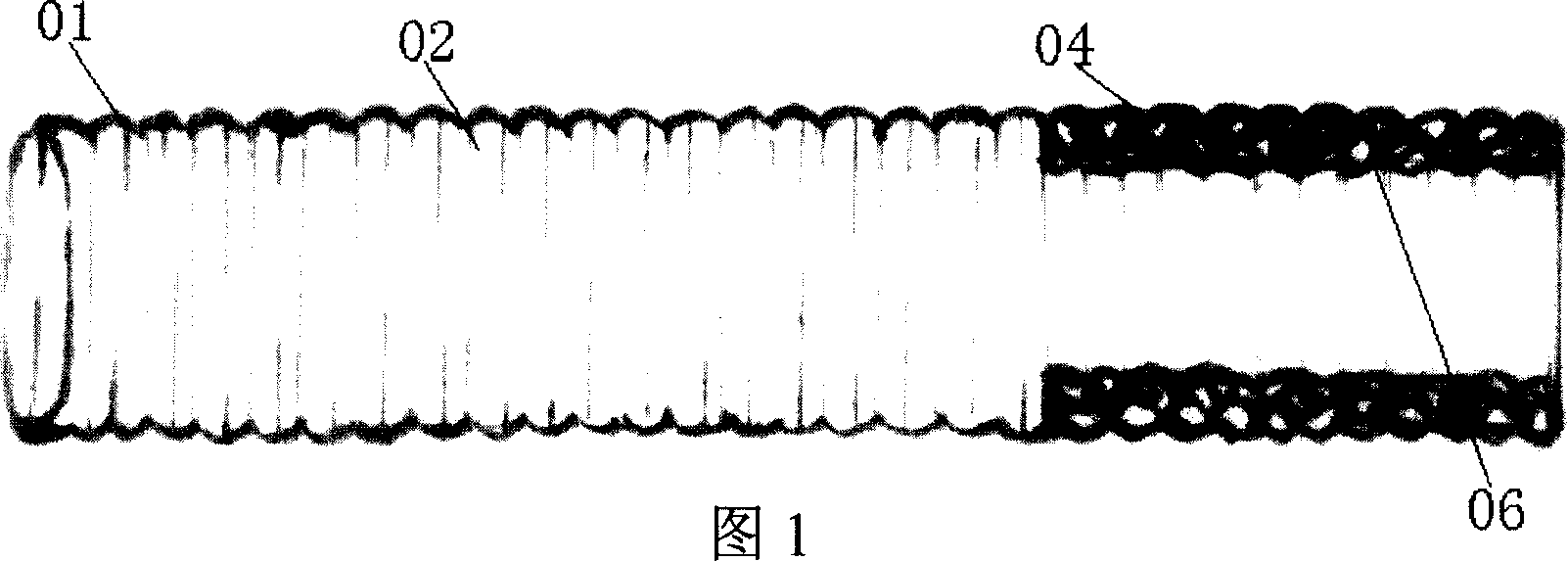

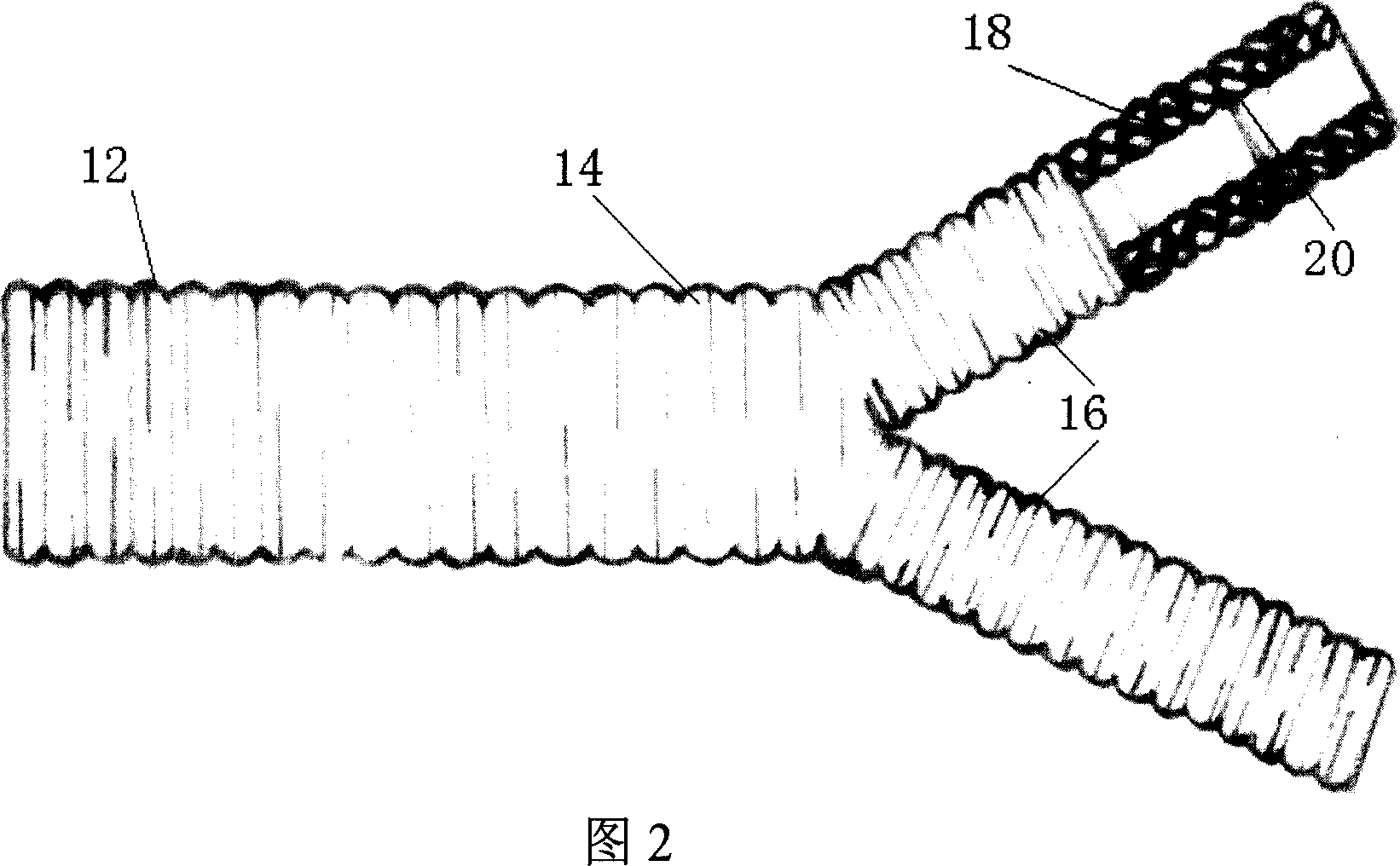

[0027] Example 2: Coated artificial vascular prosthesis

[0028] The first step will contain collagen (extract from bovine Achilles tendon according to example 1) concentration and be that the collagen protein mixed solution of 1.5% is filled in the syringe of 50ml, this collagen protein mixed solution contains 12% glycerin simultaneously, the ethanol of 20% and distilled water with a viscosity of about 30,000 centipoise. The syringe is connected to one end of the synthetic woven artificial blood vessel, and the collagen mixture is pushed into the lumen of the artificial blood vessel. At the same time, massage techniques are used to spread the coating liquid evenly on the inner wall of the lumen, and the excess collagen mixture is removed from the artificial blood vessel. The other end of the vessel is removed. In the second step, a 5% silk fibroin mixture containing silk fibroin (purified from tussah silk according to example 1) at a concentration of 5% is filled in a 50ml s...

example 3

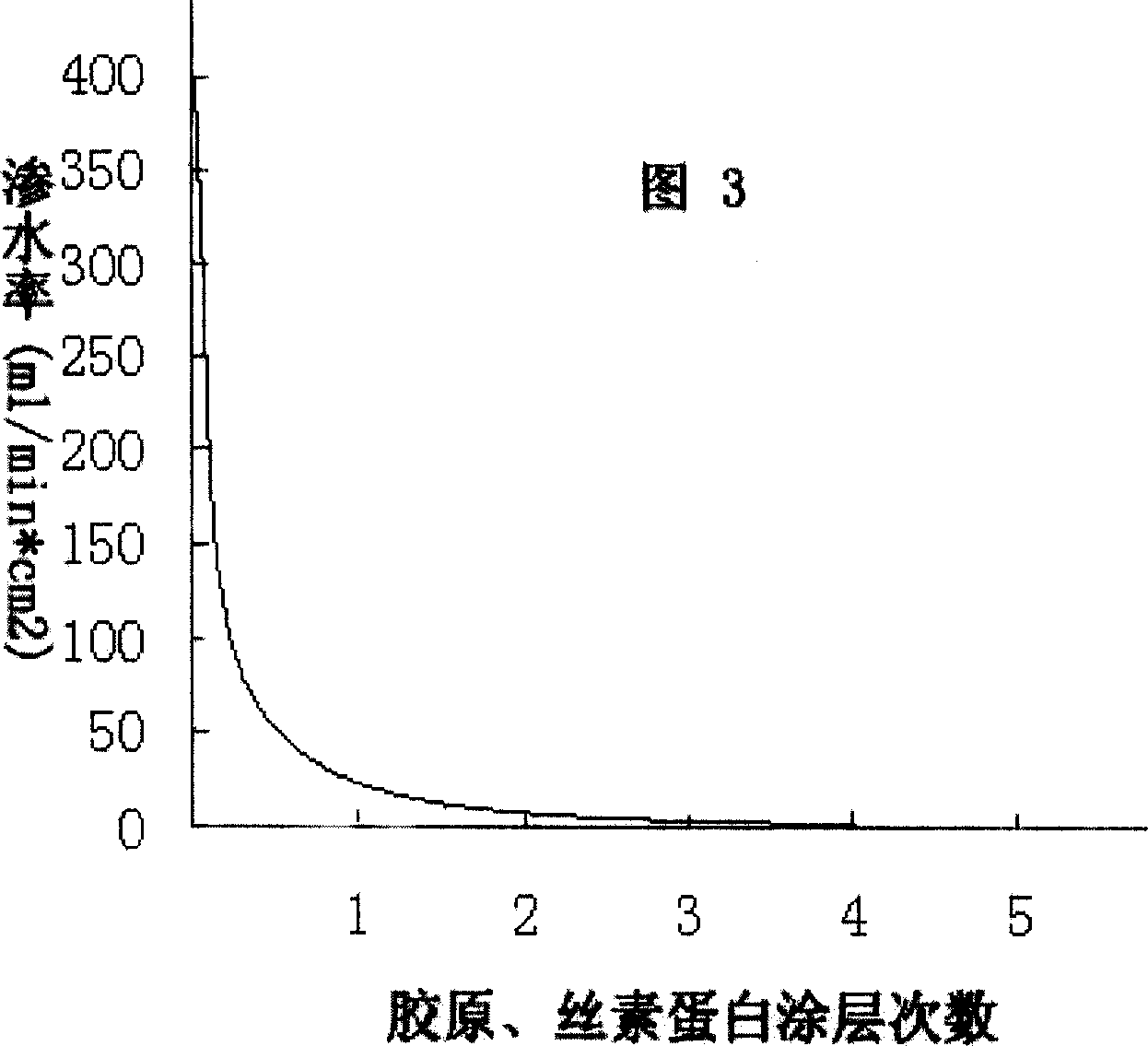

[0030] Example 3: Comparison of blood permeability of artificial blood vessels before and after coating

[0031] According to the method of Example 2, the artificial blood vessel of collagen and silk fibroin layered coating that does not leak blood is prepared as follows, and 5 synthetic woven artificial blood vessels with a diameter of 8 mm and a length of 12 cm are randomly selected and combined with a blood reservoir Connected, under the pressure of 120mmHg, make the heparinized blood pass through the blood vessel, collect the leaked blood and measure it (unit: ml / min*cm 2 ). Test results The blood permeability of the five artificial blood vessels are: 0.03, 0.0, 0.03, 0.0 and 0.0, the average blood permeability is 0.012ml / min*cm 2 , close to zero.

[0032] In order to compare with the uncoated woven artificial blood vessel, the uncoated artificial blood vessel was selected to repeat the above experiment, and the average blood permeability was measured to be 28.4ml / min*cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com