Tension-free hernia patch and preparation method thereof

A tension-free, patch technology, applied in the fields of medical science, prosthesis, coating, etc., can solve the problems of infection and skin sinus, rough surface of the patch, damage to surrounding tissues, etc., to reduce abdominal adhesion and intestinal fistula, The effect of good mechanical properties matching and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

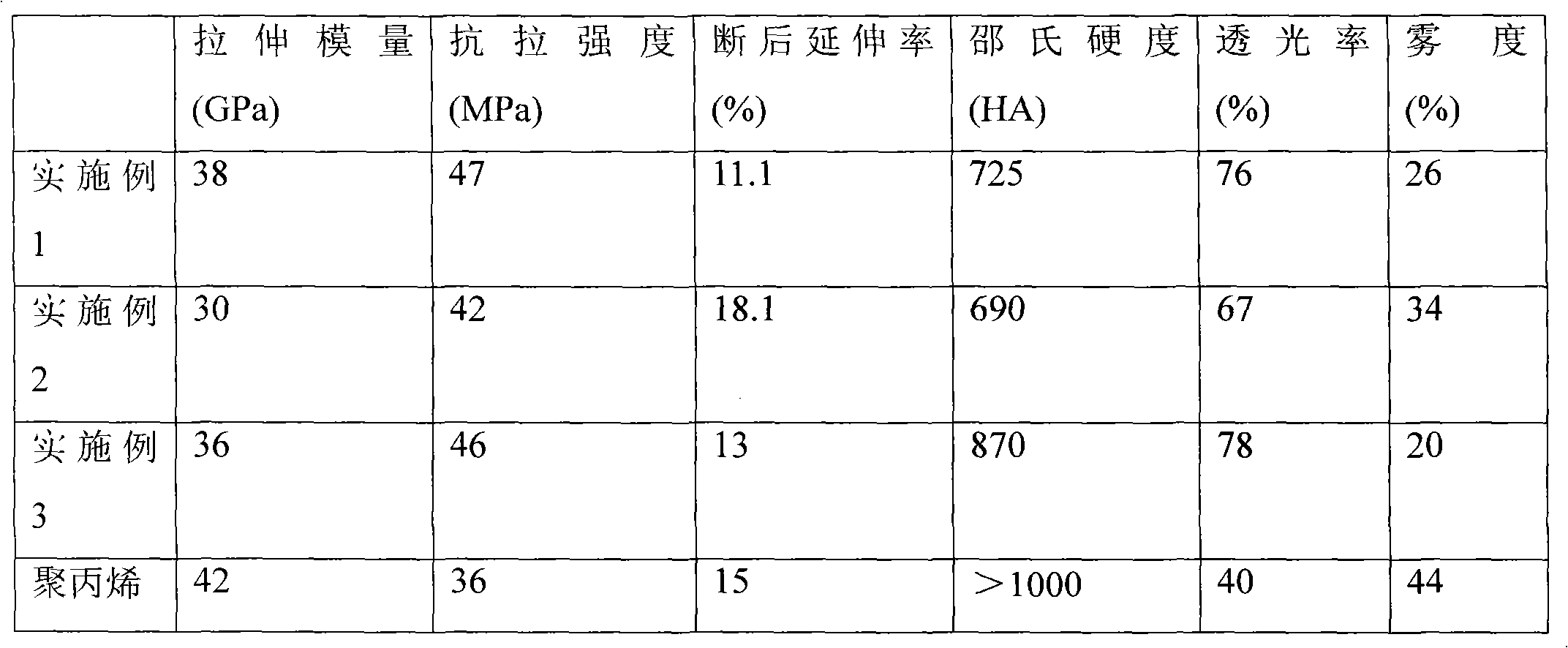

Embodiment 1

[0064] Step 1: Put the polypropylene wire with a diameter of 50 μm in absolute ethanol to remove oil for 5 minutes, then rinse the polypropylene wire with distilled water, and put it in a stannous chloride hydrochloric acid solution with a temperature of 10 and a pH value of 1 for treatment 3min; Rinse the processed polypropylene filament with distilled water and set aside;

[0065] Wherein: tin protochloride hydrochloric acid solution is: tin protochloride is dissolved in the hydrochloric acid that molar concentration is 5mol / L, is then diluted to pH value 1 with distilled water, and the concentration of stannous chloride in the solution is 10g / L;

[0066] Step 2: Add the silicon methylation reagent to the reaction container until it is full, soak for 24 hours, pour out the reagent, rinse the reaction container with distilled water, and set aside;

[0067] Wherein: the silylating reagent is a mixture of dichloromethane and trimethylchlorosilane, and the volume percentage is d...

Embodiment 2

[0075] Step 1: Put the polypropylene wire with a diameter of 65 μm in absolute ethanol to remove oil for 5 minutes, then rinse the polypropylene wire with distilled water, and put it in a stannous chloride hydrochloric acid solution with a temperature of 15°C and a pH value of 1.5 Treat for 2 minutes; rinse the treated polypropylene silk with distilled water and set aside;

[0076] Wherein: stannous chloride hydrochloric acid solution is: tin protochloride is dissolved in the hydrochloric acid that molar concentration is 7mol / L, is then diluted with distilled water to pH value 1.5, and the concentration of stannous chloride in the solution is 15g / L;

[0077] Step 2: Add the silicon methylation reagent to the reaction container until it is full, soak for 24 hours, pour out the reagent, rinse the reaction container with distilled water, and set aside;

[0078] Wherein: the silylating reagent is a mixture of dichloromethane and trimethylchlorosilane, and the volume percentage is ...

Embodiment 3

[0086] Step 1: Put the polypropylene wire with a diameter of 80 μm in absolute ethanol to remove oil for 5 minutes, then rinse the polypropylene wire with distilled water, and put it in a stannous chloride hydrochloric acid solution with a temperature of 20°C and a pH value of 2 Treat for 5 minutes; rinse the treated polypropylene silk with distilled water and set aside;

[0087] Wherein: stannous chloride hydrochloric acid solution is: tin protochloride is dissolved in the hydrochloric acid that molar concentration is 9mol / L, is then diluted to pH value 2 with distilled water, and the concentration of stannous chloride in the solution is 20g / L;

[0088] Step 2: Add the silicon methylation reagent to the reaction container until it is full, soak for 24 hours, pour out the reagent, rinse the reaction container with distilled water, and set aside;

[0089] Wherein: the silylating reagent is a mixture of dichloromethane and trimethylchlorosilane, and the volume percentage is dich...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com