Method of manufacturing gradual-change bore diameter stainless steel antipriming pipe

A technology of stainless steel and porous tubes, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of increasing the manufacturing cost of metal porous materials, not stating the performance, unfavorable for large-scale and wide application, etc., to achieve the improvement of demoulding success efficiency, ensure filtration accuracy, and improve the effect of air permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

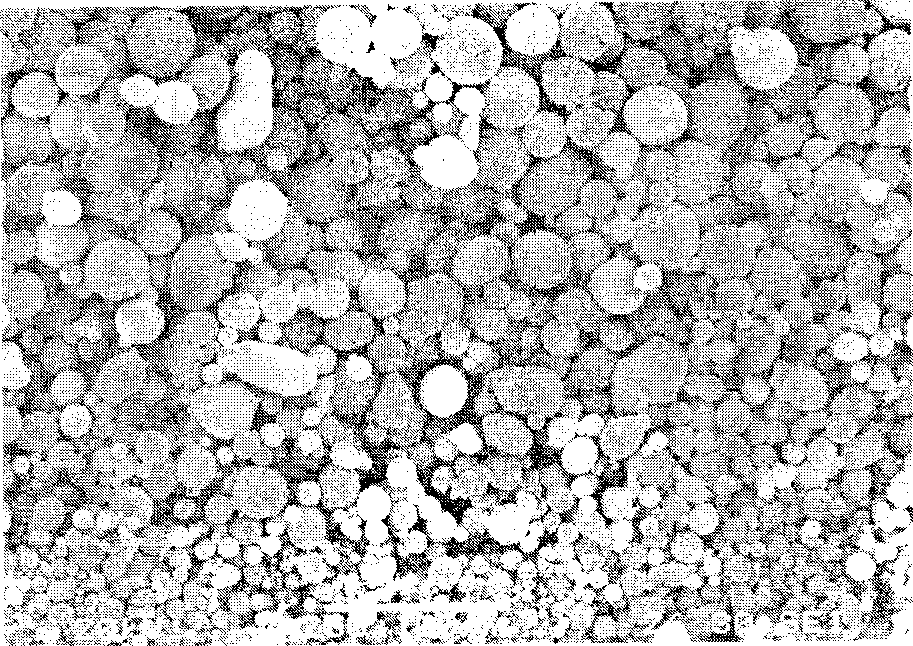

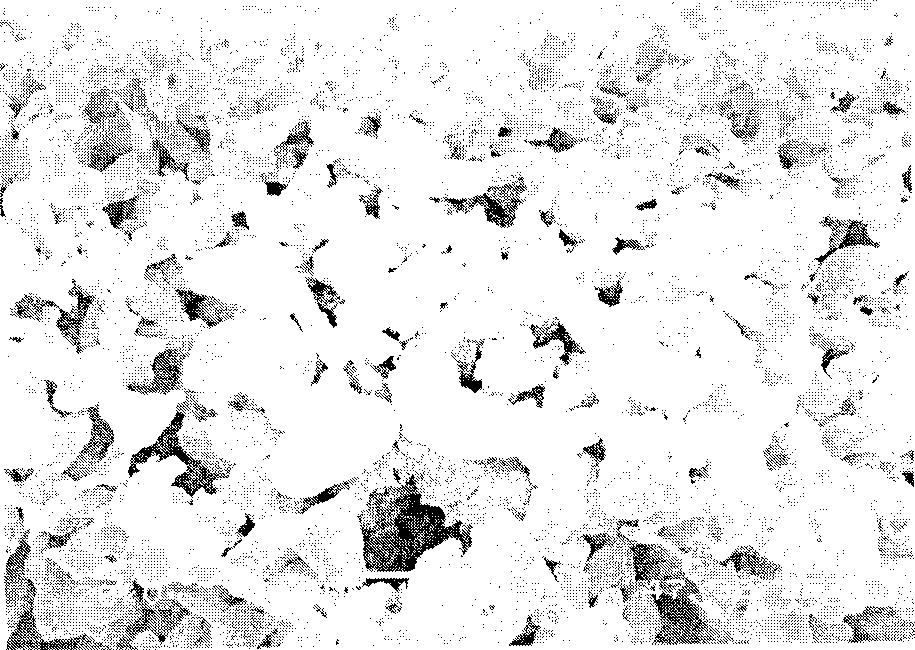

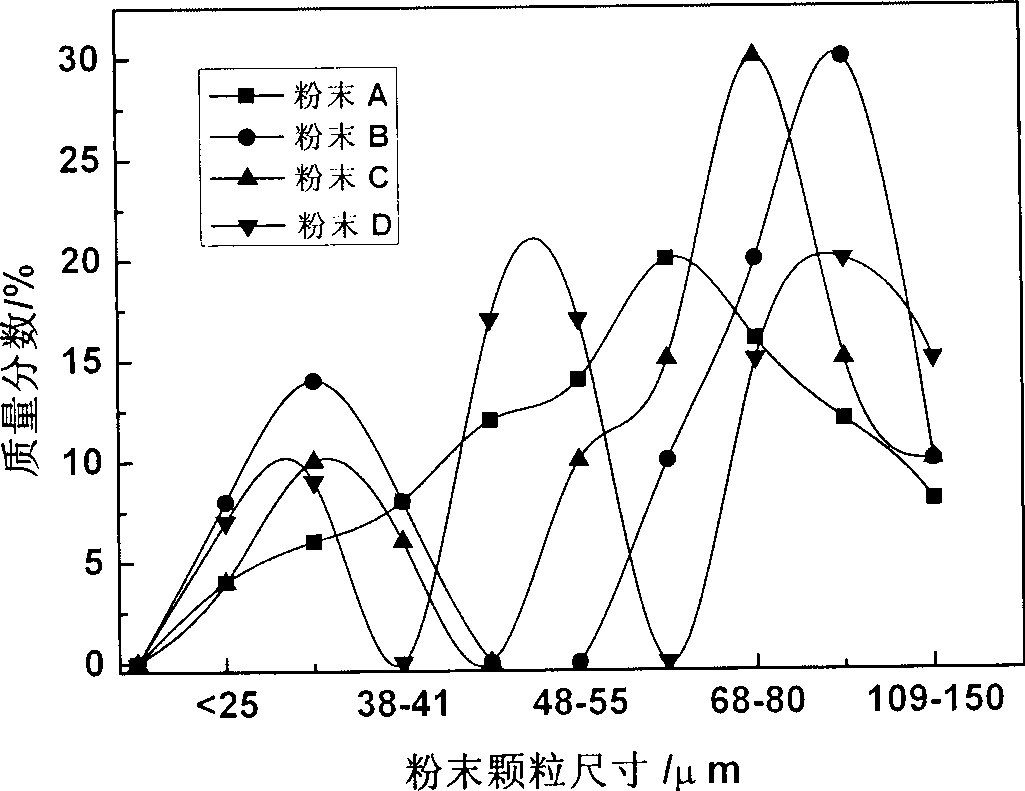

[0036] Take the irregular shape stainless steel (304L) powder A (such as image 3Shown), mix with the polyvinyl alcohol solution that mass percent concentration is 10%, the solid content of the powder suspension that obtains after mixing is 20% (mass percentage), adds getter in the powder suspension and removes the polyvinyl alcohol in the powder suspension Gas, after stirring evenly, pour it into the two-half split rigid tube mold, and put it on the centrifuge for centrifugation; the speed of the centrifuge is adjusted from 0 to 3000 rpm, and the centrifugation time is 15 minutes; Half-type bisecting rigid tube mold, pour out the clear liquid in the mold, dry the stainless steel porous tube with gradient aperture and demould; sinter the porous tube in a vacuum furnace; finally use the FBP-I porous material tester to test The prepared gradient aperture stainless steel porous tube has a maximum pore diameter of 43 μm and a relative air permeability of 540 m 3 / m 2 ·KPa·h.

Embodiment 2

[0038] Take the irregular shape stainless steel (304L) powder B (such as image 3 Shown), mix with the polyvinyl alcohol solution that mass percent concentration is 5%, the solid content of the powder suspension that obtains after mixing is 10% (mass percentage), adds getter in the powder suspension and removes in the powder suspension Gas, after stirring evenly, pour it into the two-half split rigid tube mold, and put it on the centrifuge for centrifugation; the speed of the centrifuge is adjusted from 0 to 3000 rpm, and the centrifugation time is 15 minutes; Half-type bisecting rigid tube mold, pour out the clear liquid in the mold, dry the stainless steel porous tube with gradient aperture and demould; sinter the porous tube in a vacuum furnace; finally use the FBP-I porous material tester to test The prepared gradient aperture stainless steel porous tube has a maximum pore diameter of 21 μm and a relative air permeability of 417m 3 / m 2 ·KPa·h.

Embodiment 3

[0040] Weigh the irregular shape stainless steel (304L) powder C (such as image 3 Shown), mix with the polyvinyl alcohol solution that mass percent concentration is 8%, the solid content of the powder suspension that obtains after mixing is 16% (mass percentage), adds getter in the powder suspension and removes the polyvinyl alcohol in the powder suspension Gas, after stirring evenly, pour it into the two-half split rigid tube mold, and put it on the centrifuge for centrifugation; the speed of the centrifuge is adjusted from 0 to 3000 rpm, and the centrifugation time is 15 minutes; Half-type bisecting rigid tube mold, pour out the clear liquid in the mold, dry the stainless steel porous tube with gradient aperture and demould; sinter the porous tube in a vacuum furnace; finally use the FBP-I porous material tester to test The maximum pore diameter of the prepared gradient aperture stainless steel porous tube is 31 μm, and the relative air permeability coefficient is 444m 3 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com