Side-tracking slim hole layered fracturing string and side-tracking slim hole layered fracturing method

A technology of layered fracturing and side-drilling, which is applied in wellbore/well components, earth-moving drilling and production of fluids, etc., can solve the problems of incomplete fracturing stimulation, unreliable stratification, and no field application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

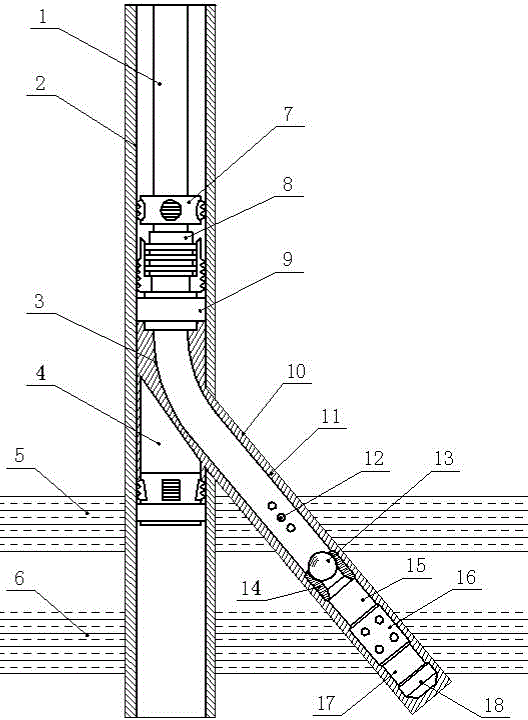

[0030] This embodiment provides a sidetracking slim hole layered fracturing string, including a casing 2, a first tubing 1, a tubing anchor 7, and a fracturing plug 8 arranged in the casing 2 and connected sequentially from top to bottom, As well as the liner string, there is a lateral borehole on the casing 2, the upper end of the liner string is connected to the fracturing plug 8, and the lower end passes through the lateral borehole;

[0031] The liner string is composed of a hanger 9, a second oil pipe 3, a ball seat 14, a third oil pipe 15, a soluble eye pipe 16, a fourth oil pipe 17, and a liner shoe 18 connected sequentially from top to bottom. The hanger 9 is connected to the fracturing plug 8 .

[0032] The working process of this embodiment takes a slim hole of Φ118mm drilled inside the original wellbore of Φ124mm as an example: figure 1 As shown, a skewer 4 is lowered into the casing 2, and the skewer 4 is locked on the inner wall of the casing 2. Through the skewe...

Embodiment 2

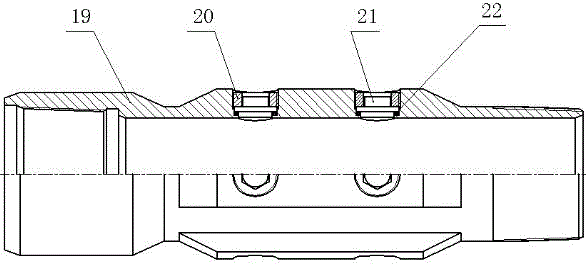

[0035] On the basis of Embodiment 1, this embodiment provides a sidetracking slim hole layered fracturing string, the soluble hole pipe 16 includes a body 19, and the body 19 is provided with a plurality of radial holes, Sealing ring 22, soluble plug 21, nut 20 are all housed in each radial hole, and described nut 20 is threadedly connected with body 19, and sealing ring 22 is pressed tightly on the body 19 by soluble plug 21 On the step inside the radial hole. like figure 2 shown.

[0036] In this embodiment, the fracturing plug 8 is a compression packer, and the fracturing plug 8 is inserted into the stepped hole of the hanger 9 . The compression packer can seal a large annular gap by using the large expansion rate performance of the compression rubber cartridge, and has a high pressure bearing capacity.

[0037] Wherein, the outer surface of the main body 19 has longitudinal guide grooves. The diversion groove can ensure the smooth flow of cement 11 during well cementi...

Embodiment 3

[0039] This embodiment provides a layered fracturing method for a sidetracked slim hole. A sidetracked wellbore 10 is drilled inside the original wellbore, a liner string is lowered into the sidetracked wellbore 10, and the liner string is cemented. Finally, the fracturing channel of the lower reservoir 6 is opened, and the fracturing operation of the lower reservoir 6 is carried out after the tailpipe string is connected with the wellhead tool string; the upper reservoir 5 is perforated, and then isolated from the lower reservoir 6, and the upper reservoir 5 Carry out fracturing construction.

[0040] The fracturing method does not need to run in fracturing tools, which not only meets the construction requirements of large displacement fracturing, but also avoids the risk of running in downhole tools.

[0041] Example 3:

[0042] On the basis of Embodiment 1 or Embodiment 2, this embodiment provides a layered fracturing method for a sidetracked slim hole, in which a sidetrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com