Artificial blood vessel collagen pre-coagulation coating

A technology of artificial blood vessels and collagen, applied in coatings, medical science, prostheses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Example 1: Extraction of collagen solution

[0022] Remove the fat and fascia from the fresh Achilles tendon, freeze it at -10°C until it hardens, remove the residual fascia on the surface of the Achilles tendon with a scalpel, and cut it into 1mm×1mm slices along the direction of the tendon fibers. Thin slices were washed repeatedly with distilled water and weighed. With 0.1% (mass fraction) NaCO 3 The solution was soaked for 2 hours, rinsed 5 times with distilled water, filtered the aqueous solution with a stainless steel wire mesh, dried, put into a container, and added 0.3% (mass fraction) an appropriate amount of acetic acid solution (pH=2-3). Stir slowly for 3-5 days under temperature control between 0-4°C, then centrifuge at 200r / min with a high-speed refrigerated centrifuge, take the supernatant and add 1% (mass fraction) H 2 o 2 Solution, after mixing, let it stand for 4h. Use 7% trisodium citrate solution to adjust the pH value to 5, filter off the precip...

example 2

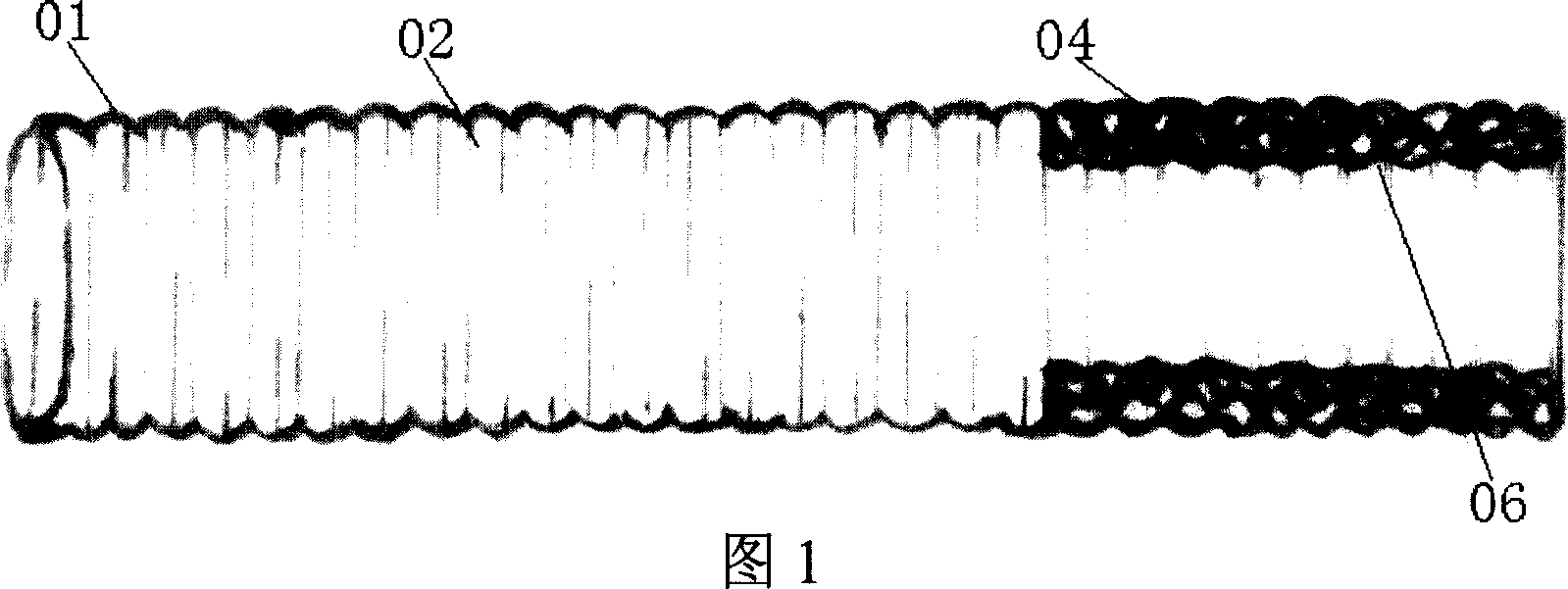

[0023] Example 2: Coated artificial vascular prosthesis

[0024]Contain 2% collagen protein (extract from bovine Achilles tendon according to example 1) concentration and fill in the syringe of 50ml with the collagen protein mixed coating solution, this collagen protein mixed coating solution contains 12% glycerin simultaneously, the ethanol of 20% and distilled water with a viscosity of about 31,000 centipoise. The syringe is connected to one end of the synthetic woven artificial blood vessel. The collagen mixed coating liquid is pushed into the lumen of the artificial blood vessel so that the coating liquid is evenly coated on the inner wall of the lumen. One end removed. The artificial blood vessel after coating is dried at room temperature for 1 / 2 hour, and the coating drying operation is repeated at least 3 times.

[0025] After the third coating, the artificial blood vessel is cross-linked in a vacuum drying oven, the temperature is controlled at 90-110° C., and the cr...

example 3

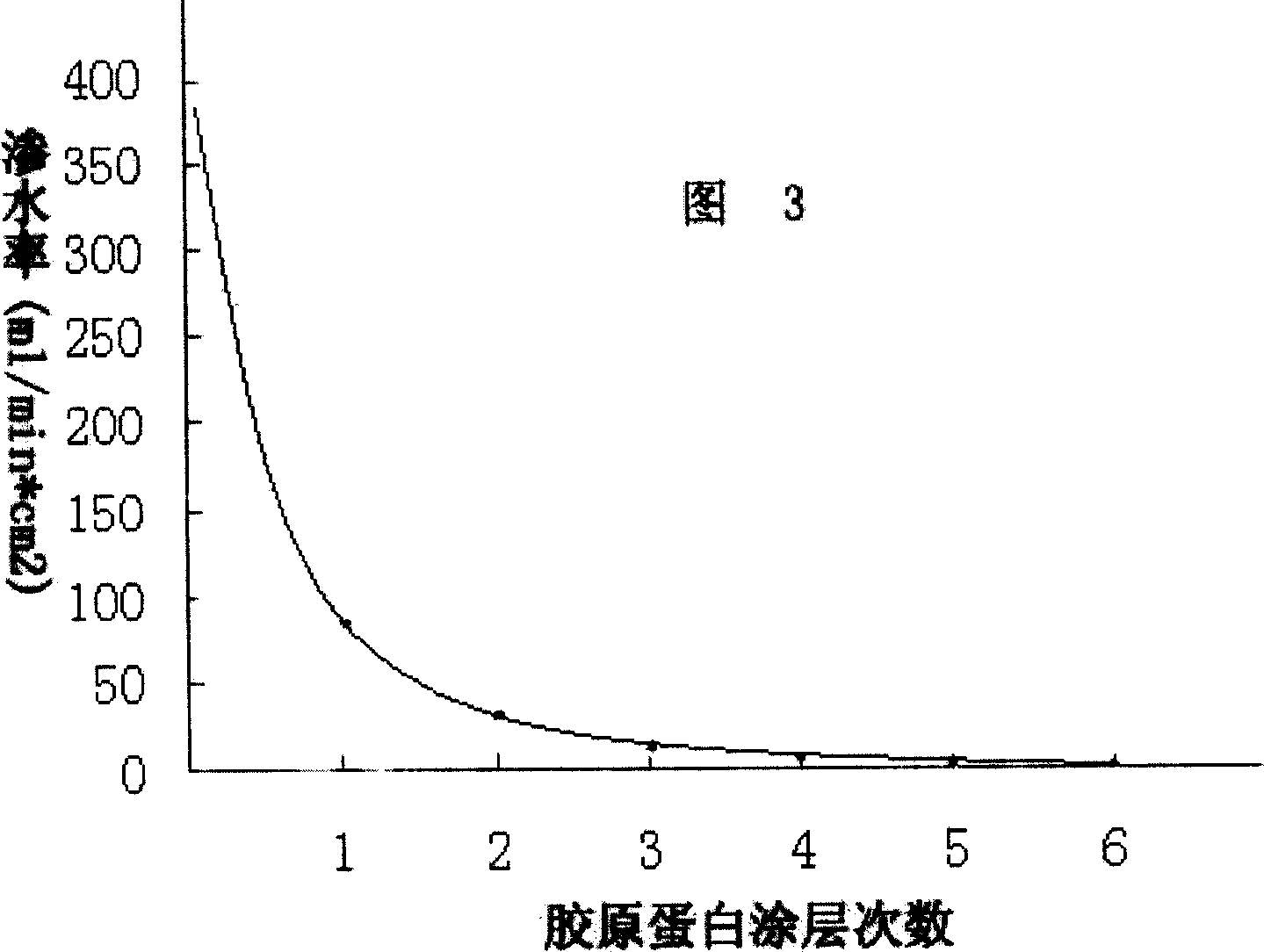

[0026] Example 3: Comparative determination of blood permeability before and after coating of artificial vascular prosthesis

[0027] According to the method of example 2, the artificial blood vessel of the collagen coating that does not leak blood is prepared and tested as follows, 5 synthetic woven artificial blood vessels with a diameter of 8 mm and a length of 12 cm are randomly selected and connected to the blood reservoir, and the blood is tested under a pressure of 120 mmHg Next, let the heparinized blood pass through the blood vessel, collect the leaked blood and measure it (unit: ml / min*cm 2 ). Test results The blood permeability of the five artificial blood vessels are: 0.03, 0.04, 0.03, 0.0 and 0.02, the average blood permeability is 0.024ml / min*cm 2 , close to zero.

[0028] In order to compare with the uncoated woven artificial blood vessel, the uncoated artificial blood vessel was selected to repeat the above experiment, and the average blood permeability was m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com