Alternating current permanent-magnet synchronous machine controller

A permanent magnet synchronous motor and controller technology, applied in AC motor control, single motor speed/torque control, control system and other directions, can solve the problem of low control accuracy, achieve stable control system, easy maintenance, and achieve constant rotation The effect of torque control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

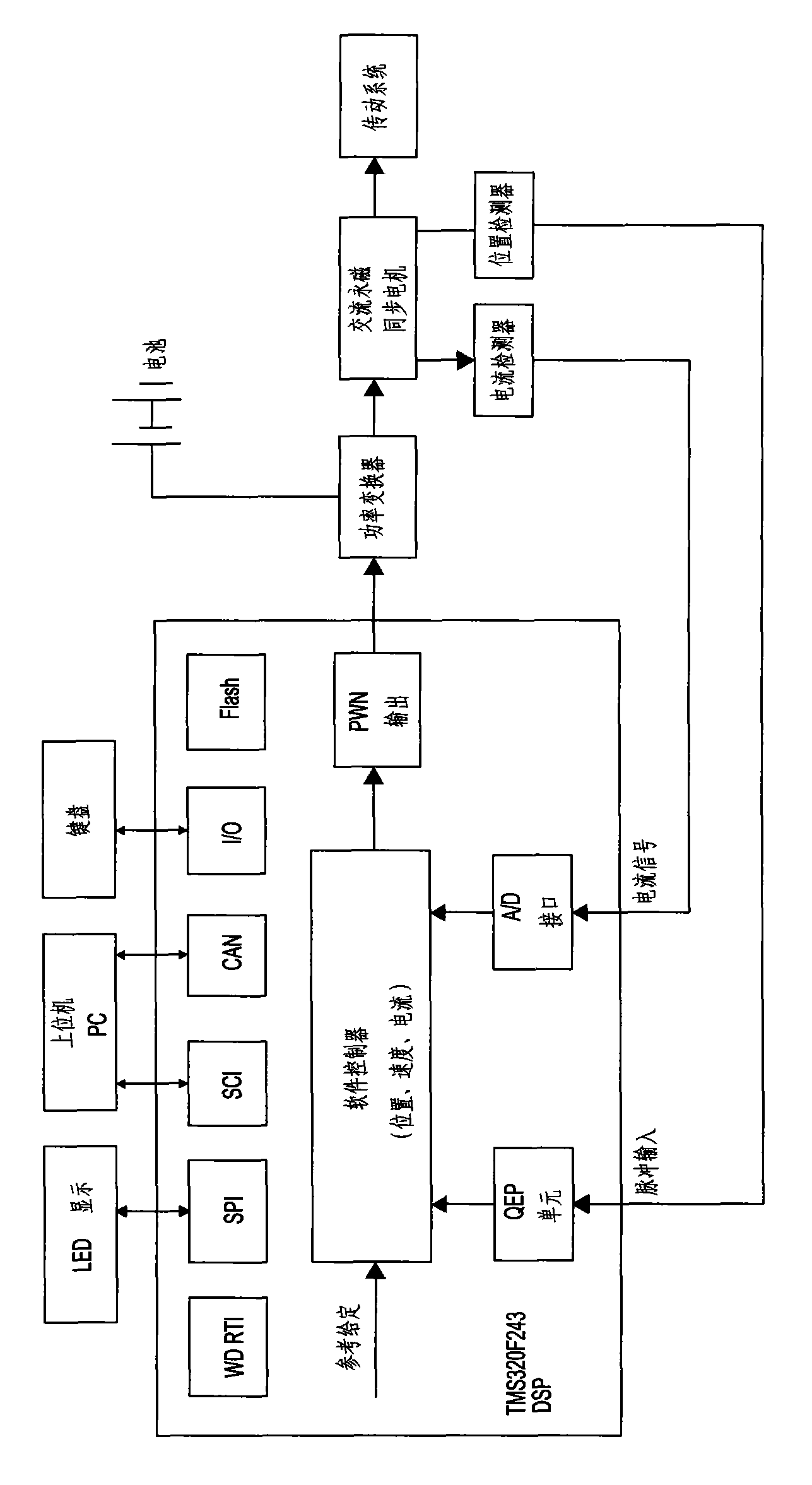

[0029] refer to figure 1 According to the AC permanent magnet synchronous motor controller provided by the present invention, it includes a DSP microprocessor (model: TMS320F243), a power changer, an AC permanent magnet synchronous motor, a position detector and a current detector, and the position detector and the current detector are used It is used to monitor the rotor position, rotor speed and phase current of the AC permanent magnet synchronous motor. When working, the position detector inputs the detected rotor position signal and rotor speed signal from the QEP unit of the DSP microprocessor, and the current detector sends them The detected current signal is input by the A / D conversion interface of the DSP microprocessor, and the DSP microprocessor calculates the given value of the current according to the input rotor position signal and rotor speed signal, and then compares it with the input current detection value. The corresponding control signal is obtained to contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com