U-shaped piston reciprocating engine

An engine and piston technology, applied in the field of piston reciprocating engines, can solve the problems of M-type and star-type engines, the limited application range of a single engine, and the single calibrated speed of the engine, so as to reduce the investment in capital and production equipment, and significantly Economic and social benefits, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical features of the present invention will be further clearly described below in conjunction with the accompanying drawings.

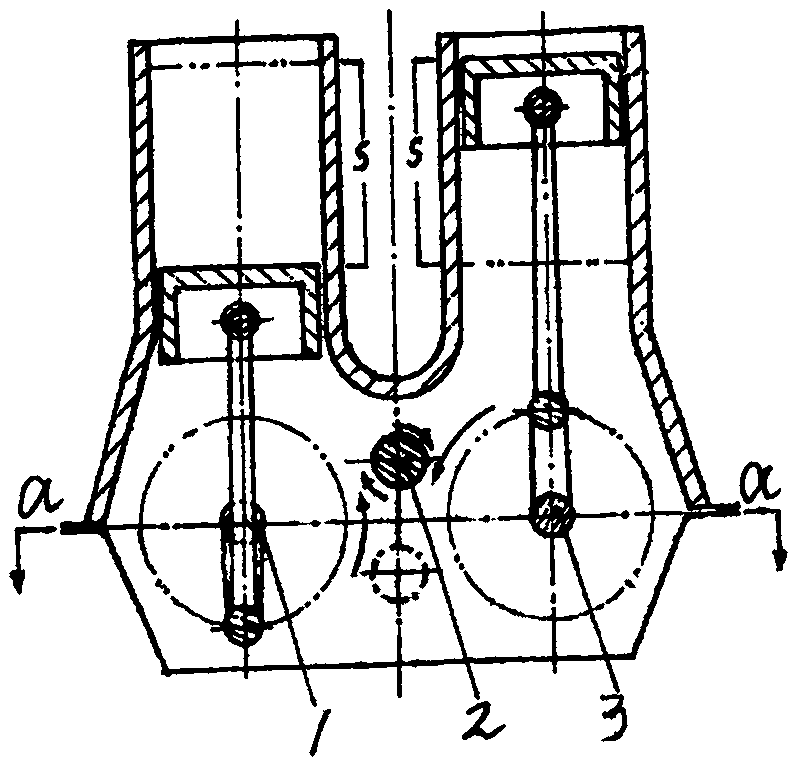

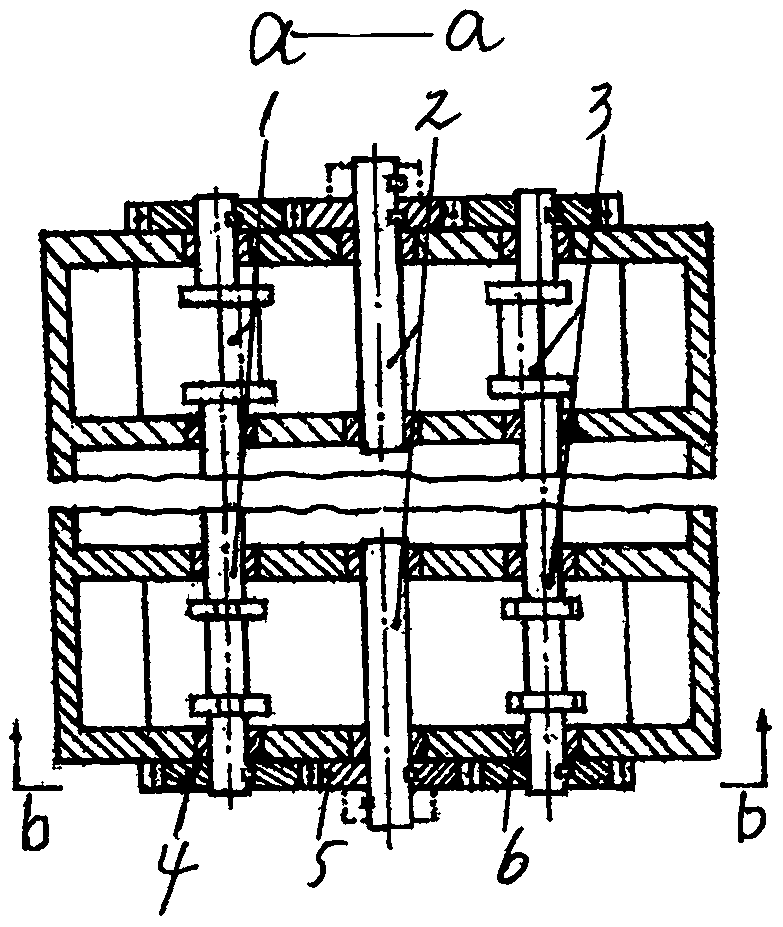

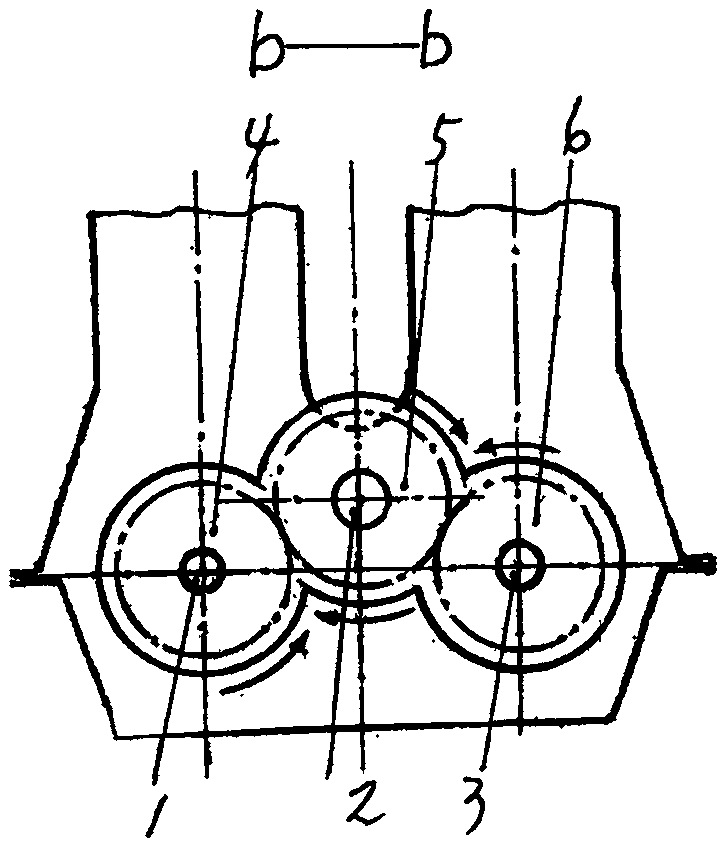

[0034] figure 1 and Figure 4 Show: two identical single-cylinders of the L-type engine are vertically parallel connected in U-type in parallel to form U-type twin cylinders; the output shaft (2) is arranged on the vertical line in the middle of the connecting line between the centers of the left and right crankshafts (1, 3), figure 1 It is shown that the output shaft (2) is located above the line connecting the centers of the two crankshafts, and may also be located below the line connecting the centers of the two crankshafts (as shown by the small dotted circle in the figure); Figure 4 It is shown that the output shaft (2) is located on the line connecting the centers of the left and right crankshafts (1, 3). The specific location is determined by the design requirements.

[0035] figure 2 and Figure 5Show: engine can only be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com