Engine performance modification or tuning kit

a technology for tuning kits and engines, applied in the direction of brake action initiation, braking system, position/direction control, etc., can solve the problems of not being able to make fuel adjustments, engine mapping is often reloaded, and the performance of modern engines can be affected, so as to improve the compatibility of the kit with different engines, the effect of avoiding alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

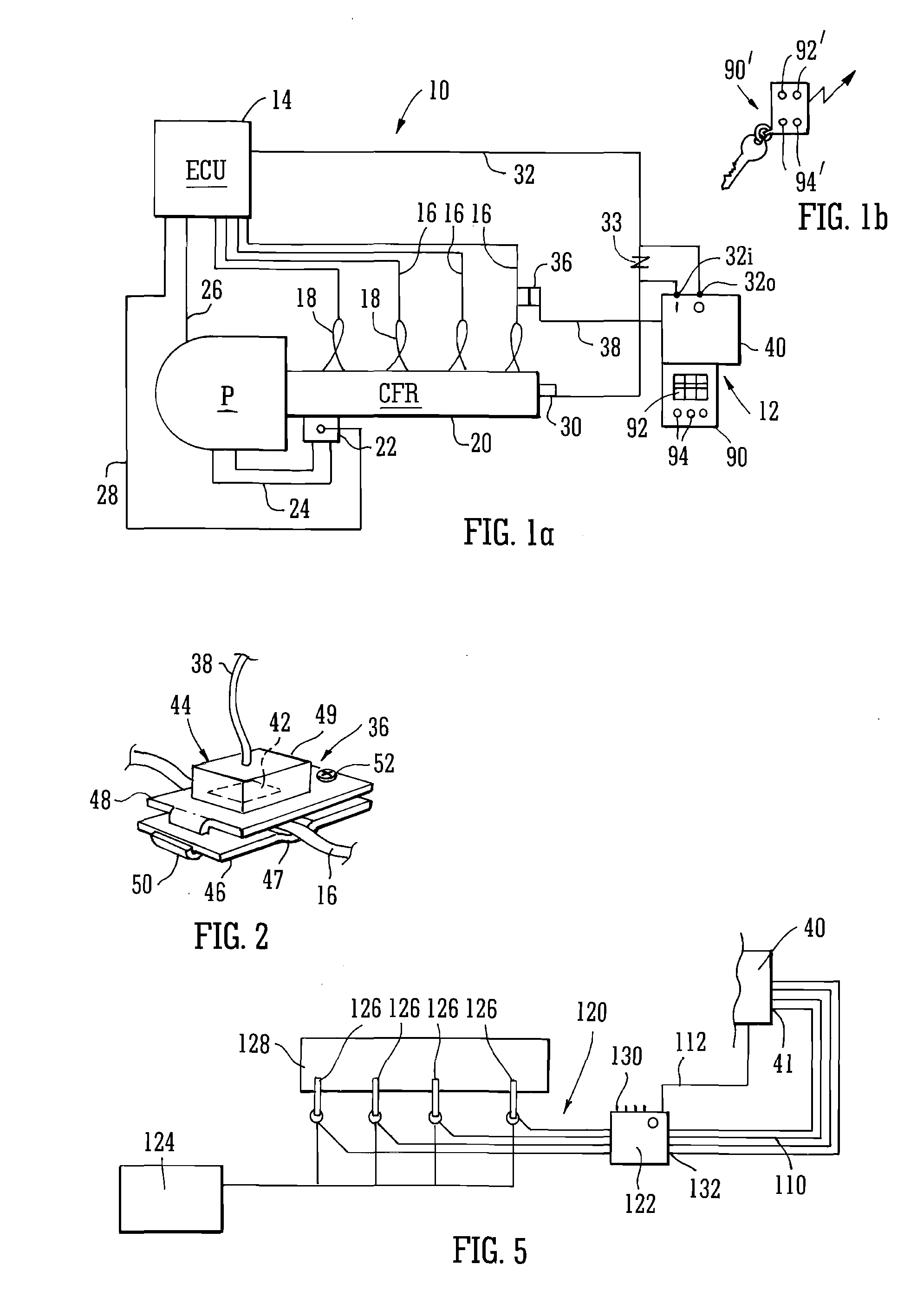

[0071]Referring to FIG. 1, an engine 10 is modified by incorporation of an engine modification kit 12 in accordance with the invention. Engine 10 comprises an engine management control unit (ECU) 14 that sends opening signals along lines 16 to each of a plurality of injectors 18 that are provided, one for each cylinder (not shown) of the engine.

[0072]The injectors 18 are supplied with fuel from a common fuel rail (CFR) 20 that is in turn pressurised by a fuel pump P. The pressure in the fuel rail is controlled by a pressure relief valve 22 that allows fuel to drain from the rail and return to the pump via line 24. Of course, the pressure developed by the pump P is variable and controlled by the ECU along line 26. However, the valve 22 can react much faster to required changes in fuel demand than can the pump itself, and the valve is controlled by the ECU 14 along line 28. The actual pressure developed in the CFR 20 is monitored by a pressure sensor 30, which reports back to the ECU ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com