Internal-combustion engine cooling system based on integrative permanent magnet synchronous motor water pump and electronic speed regulation technology

A technology of permanent magnet synchronous motor and electronic speed regulation, which is applied in the direction of engine cooling, machine/engine, and coolant flow control, etc. It can solve problems such as reduced reliability, high cost, and complex cooling system performance. The effect of stabilizing the temperature of the body and increasing the temperature of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

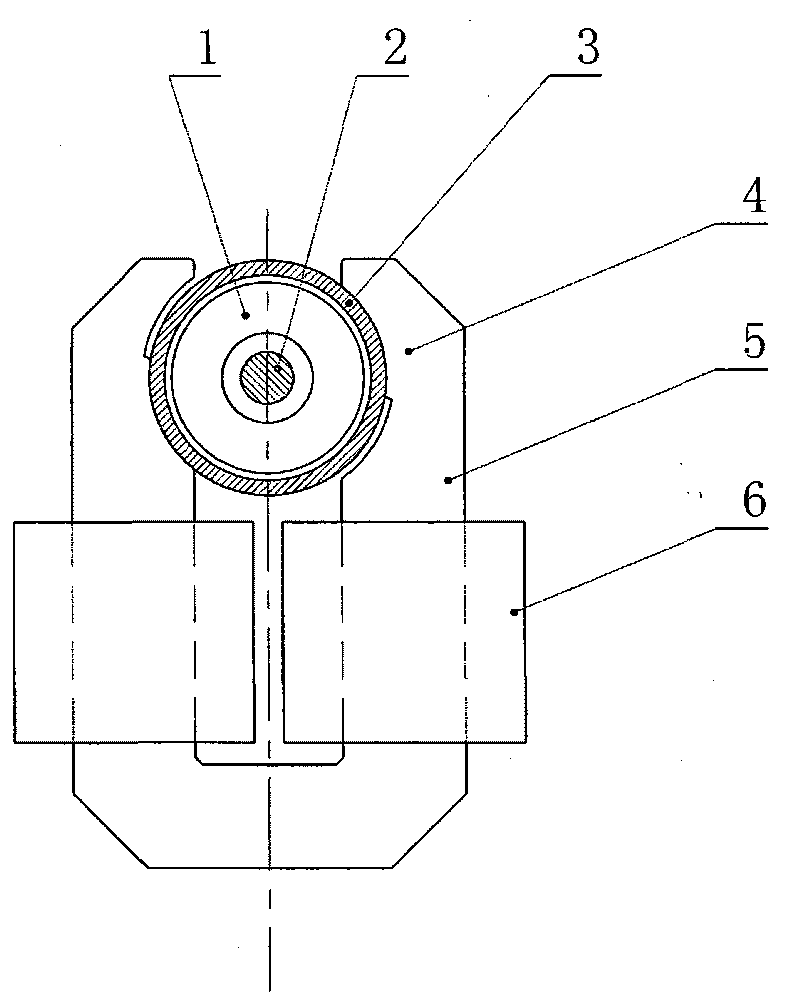

[0052] Depend on figure 1 It can be seen that the structure of the integrated permanent magnet synchronous motor water pump is as follows. 1. The permanent magnet rotor (1) generally adopts an integral two-pole magnetized permanent magnet. The permanent magnet can be ferrite, neodymium iron boron, etc. through sintering, Manufactured by bonding or injection molding, the permanent magnet rotor (1) is equipped with a shaft (2), and the water pump impeller can be directly installed on the shaft (2) to form a coaxial structure of coaxial connection and coaxial rotation. Compared with the coaxial structure that is connected around the coaxial rotation, the advantage is that a cover plate that doubles as a bearing and prevents impurities in the coolant from entering can be installed between the permanent magnet rotor (2) and the impeller. This c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com