Compensation reservoir for a cooling circuit of an internal combustion engine

a technology of internal combustion engine and cooling circuit, which is applied in the direction of liquid cooling, engine components, machines/engines, etc., can solve the problems of no longer ensuring that the coolant exiting the coolant pipe still discharges below or at the liquid level, and the risk of additional foam formation, so as to increase the viscosity of the liquid, reduce the kinetic energy of the inflowing water/gas mixture, and increase the kinetic energy of the inflowing coolant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

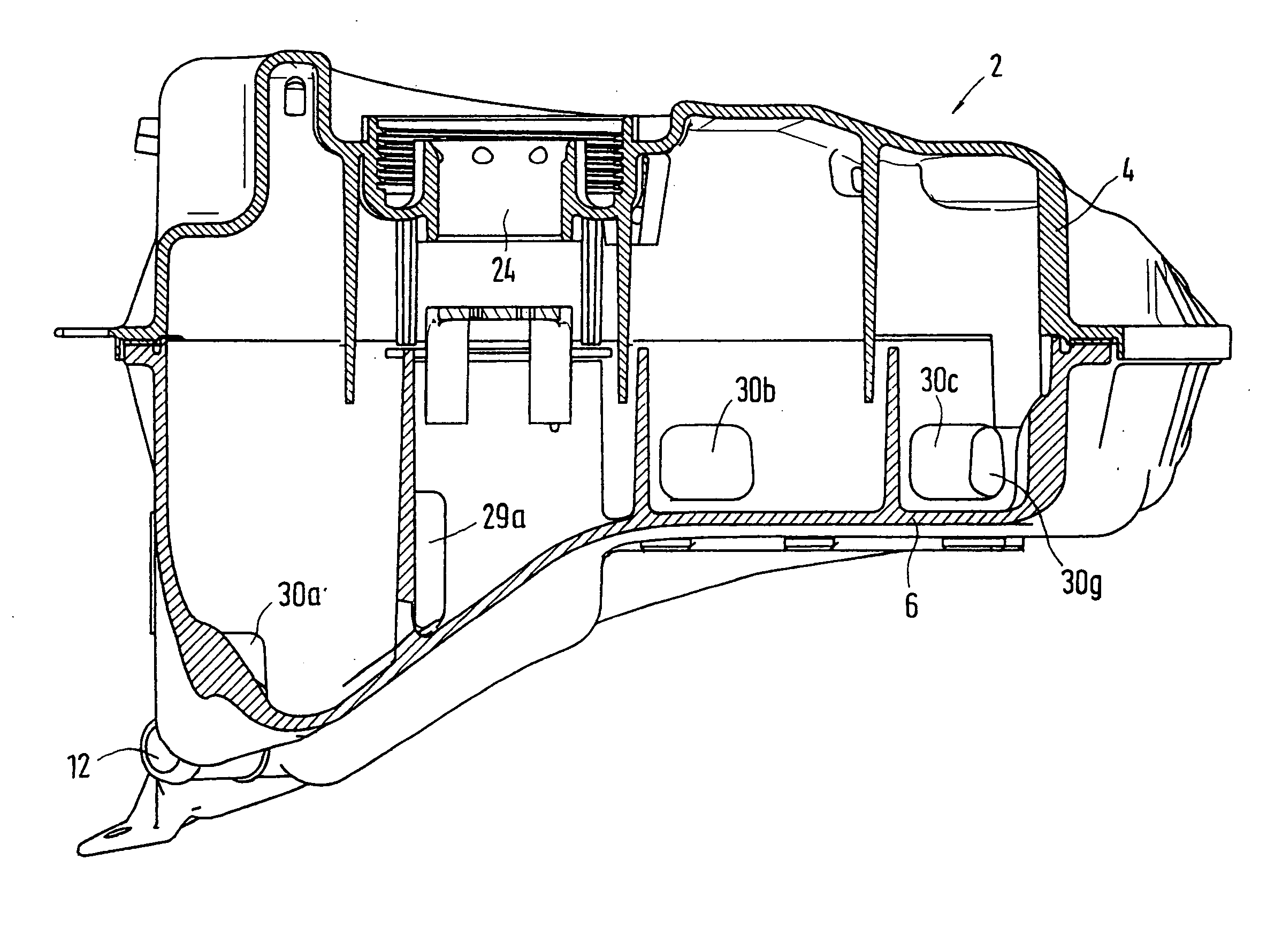

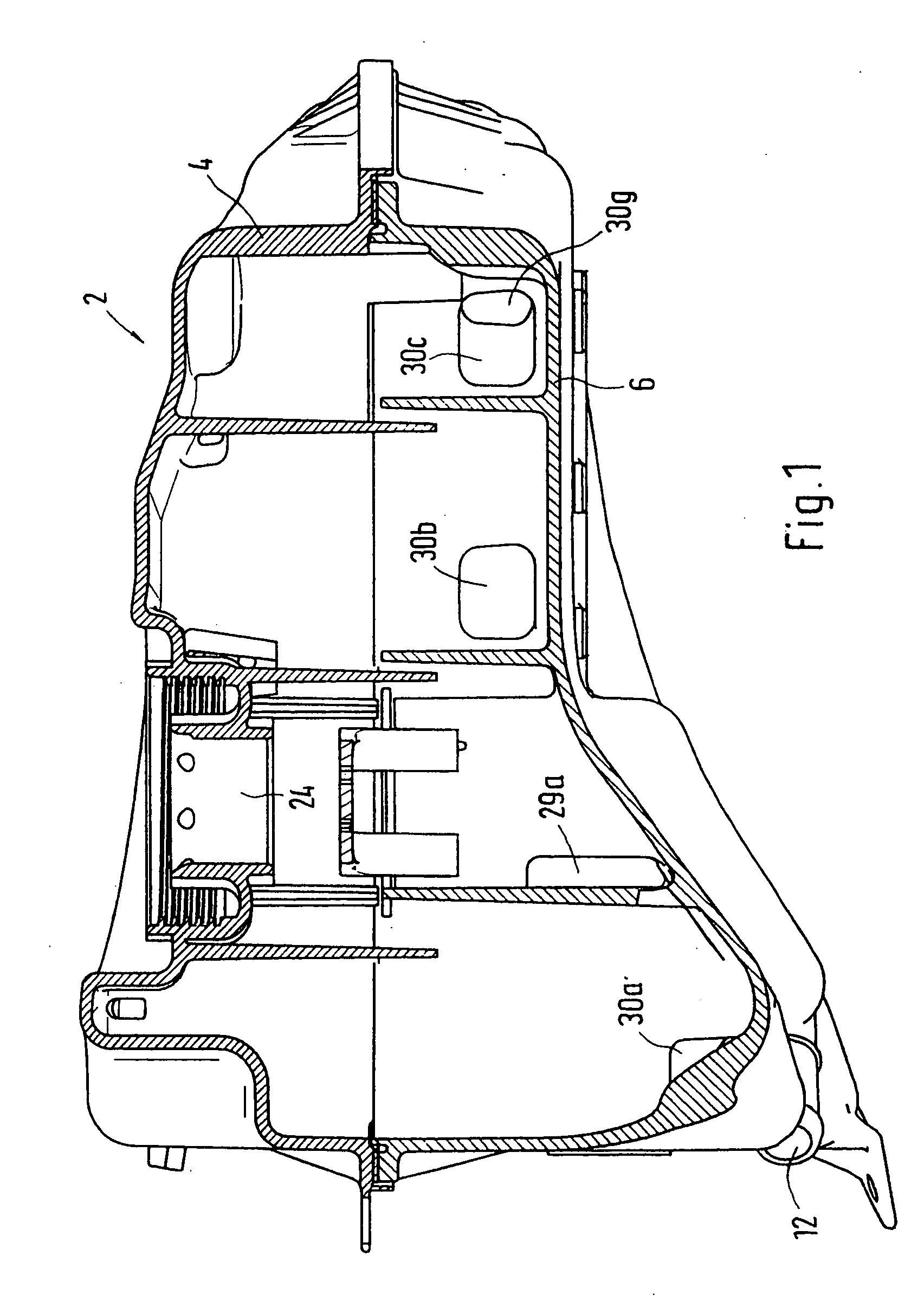

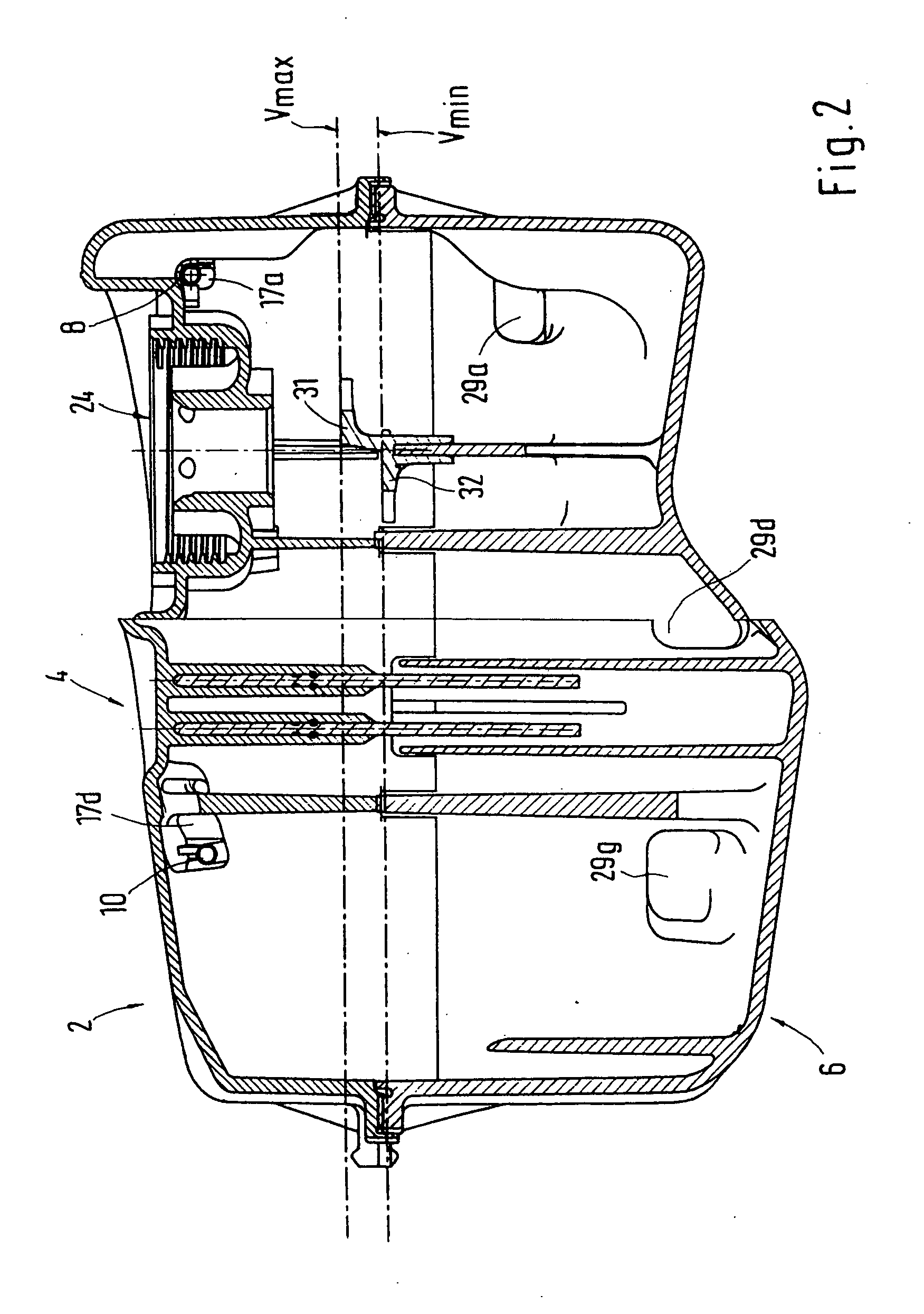

[0017] The compensating tank 2 integrated into the cooling circuit of an internal combustion engine has an upper shell 4 and a lower shell 6, which are joined, for example, by vibration welding. The coolant flows into the compensating tank 2 through two pipes integrated in the upper shell 4, hereinafter referred to as coolant pipes 8 and 10. The return flow or outlet 12 is formed in the lower shell 6. Both the upper and the lower shell 4, 6, have a chamber system, which will now be described in greater detail. In the upper shell 4, in the present example, there are twelve chambers 14a to 14l, which are formed by transverse and longitudinal walls 15a to 15i and 16a to 16h rising from the bottom of the upper shell 4. The two coolant pipes 8 and 10 introduced into the upper shell 4 are guided through openings 17a to 17c and, respectively, 17d to 17f made in the transverse walls 15a to 15c and, respectively, 15g to 15i up to the two rearmost chambers 14d and 141. The openings 17a to 17c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com