Method and apparatus for mixing fluids

a technology of fluid mixing and apparatus, applied in water cleaning, filtration separation, separation processes, etc., can solve the problems of reducing the level of hydrogen sulfide gas, releasing sulfides from sewage, and sewage contains a significant amount of potentially volatile dissolved molecular hydrogen sulfide, so as to reduce the gas emission of fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

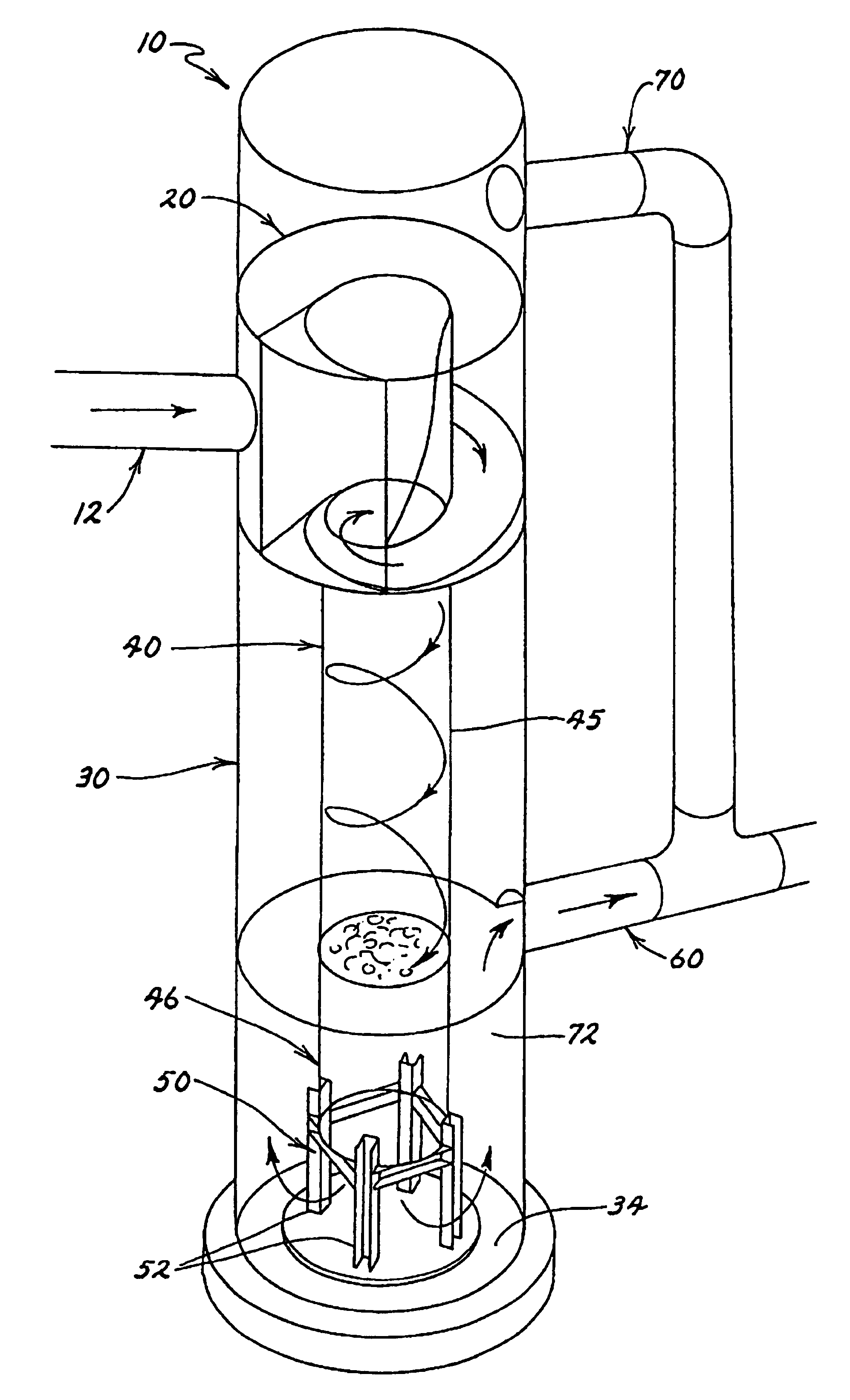

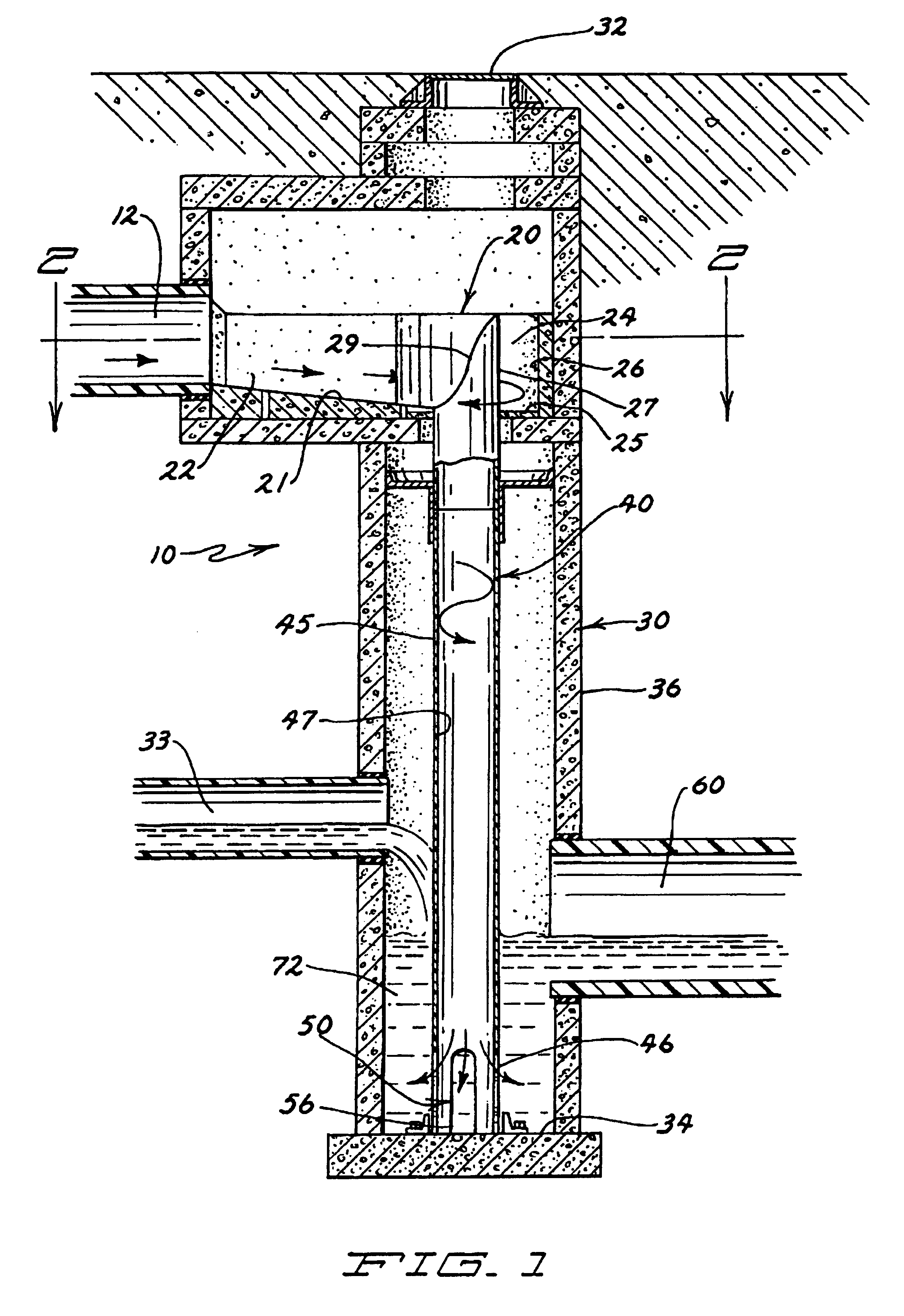

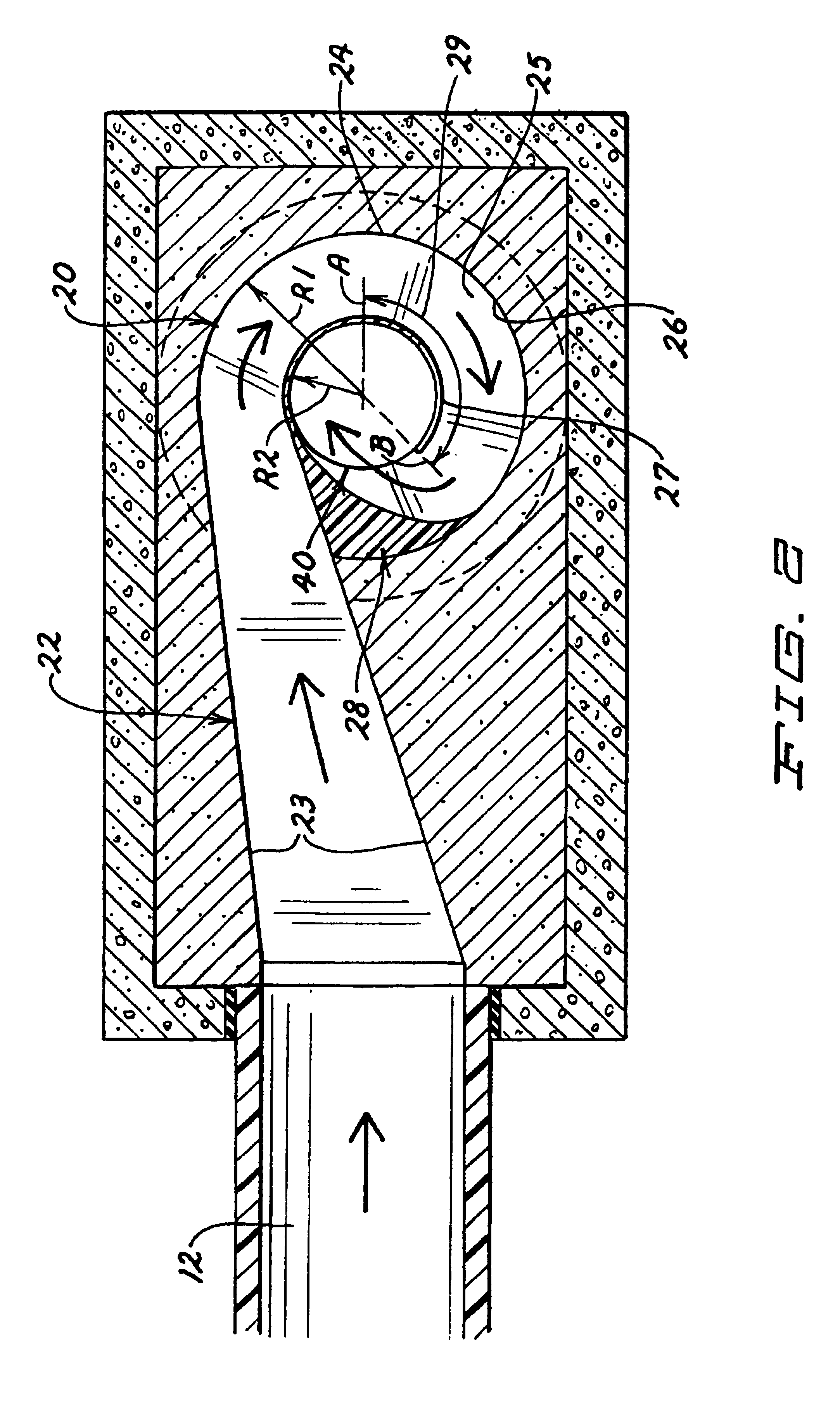

[0030]FIG. 1 illustrates in a side elevation view one embodiment of a sewer apparatus 10 constructed in accordance with the present invention. Referring to FIG. 1, the sewer apparatus 10 includes an influent line 12, a vortex form 20, a maintenance hole 30, a conduit 40, a flow exit 50, and an effluent line 60.

[0031]The maintenance hole 30 in which the vortex form 20 is disposed may be identified from street level as being below a manhole cover 32. FIG. 1 shows the maintenance hole 30 as being cylindrical in shape and oriented vertically. A lateral line 33 for inputting additional city sewer flowage into the maintenance hole 30 may be disposed below the influent line 12. The base 34 and walls 36 of the maintenance hole 30 are generally concrete. An energy dissipating pool 72, comprised of sewage, forms at the base 34 of the maintenance hole 30. An effluent line 60 is connected to the maintenance hole 30 near the top level of the energy dissipating pool 72.

[0032]As illustrated in FIG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| outer radius | aaaaa | aaaaa |

| inner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com