Separable negative pressure foaming machine with bottomless bucket, and preparation method thereof

A bottomless barrel and separate technology, which is applied in the field of foam manufacturing, can solve the problems of reduced sound absorption performance, easy chip loss, and reduced wear resistance, so as to improve foam performance, speed up production rhythm, and achieve huge economic value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

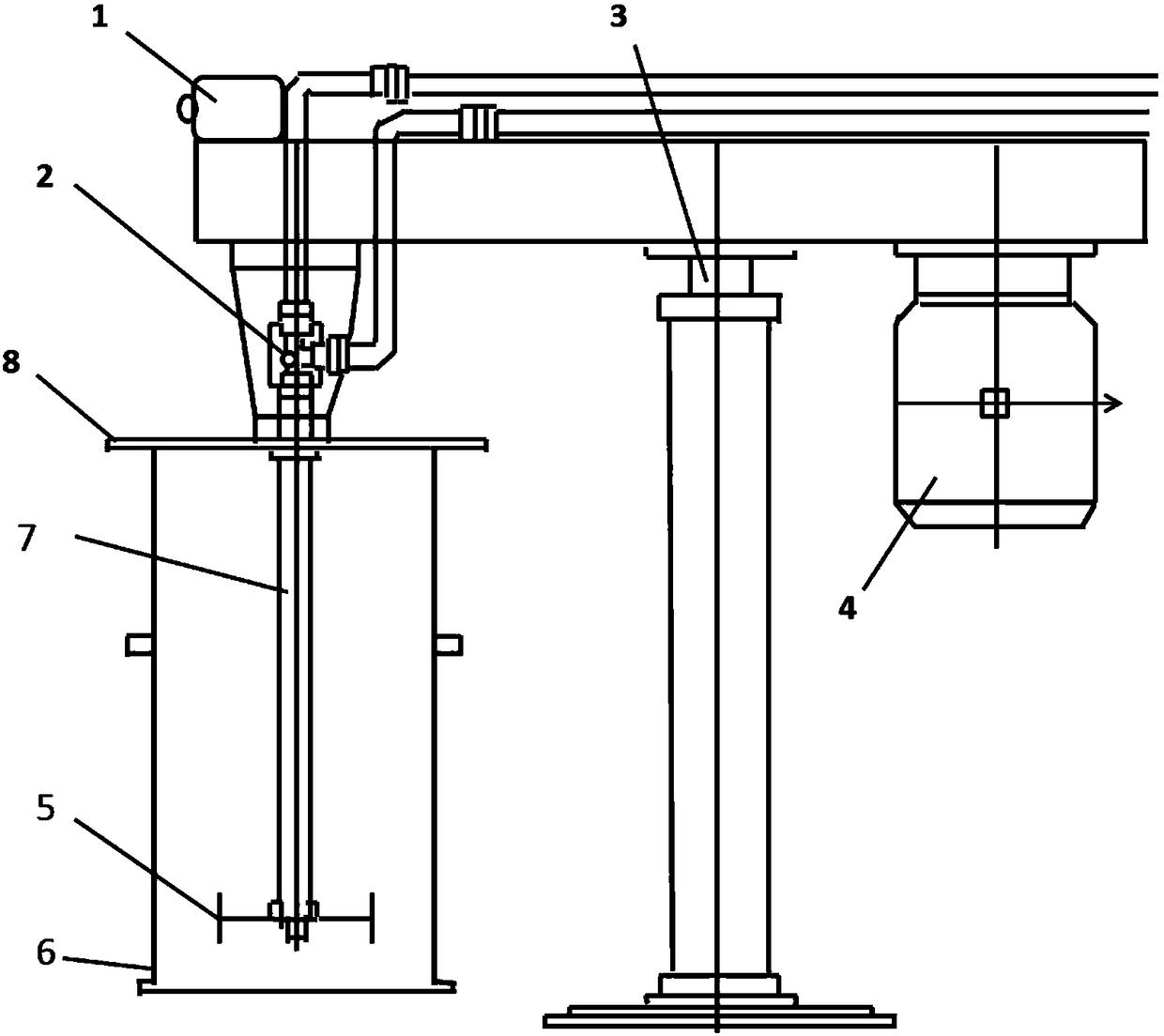

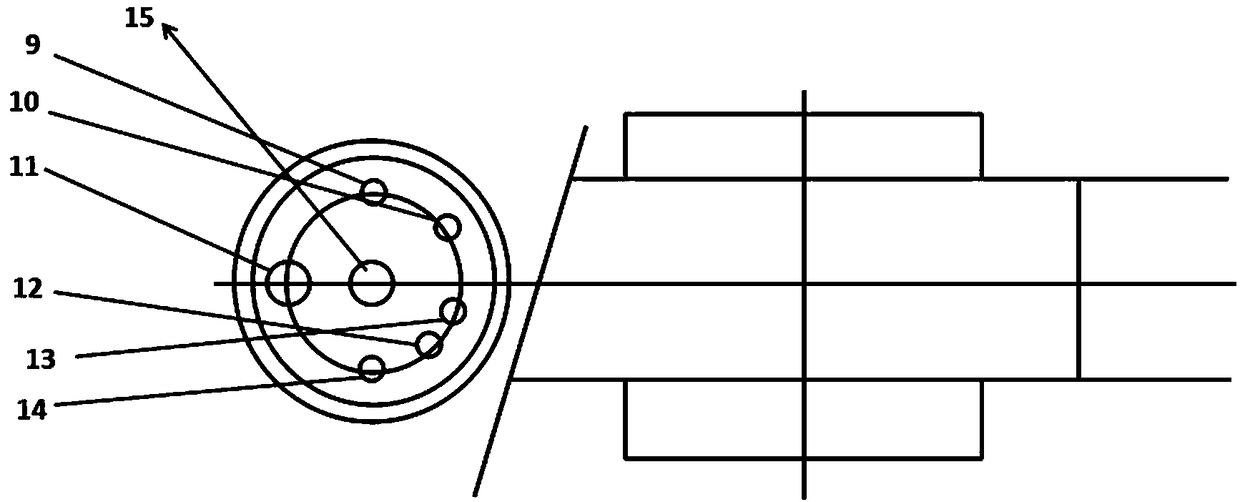

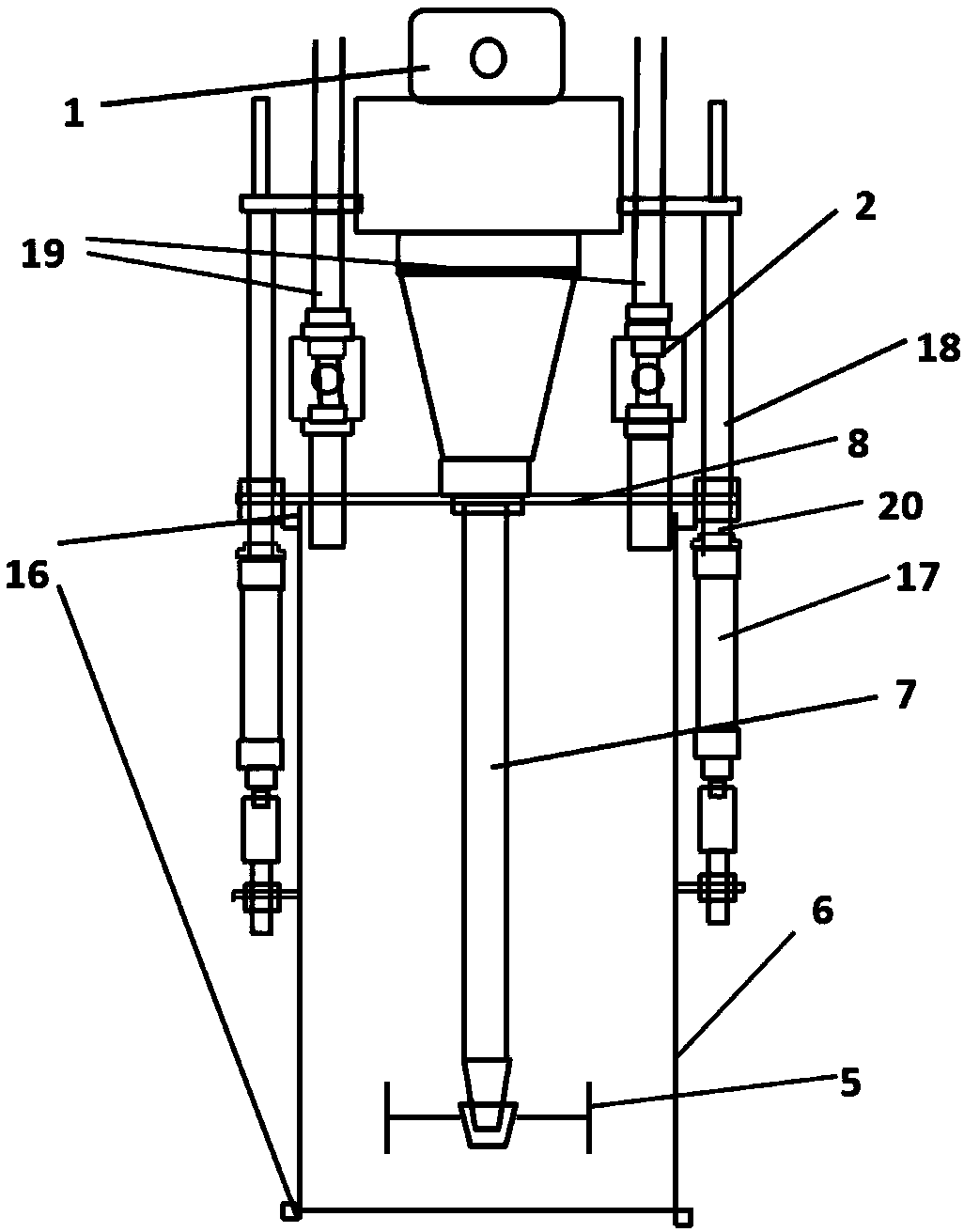

[0029] The invention discloses a detachable bottomless bucket 6 negative pressure foaming machine, which comprises a stirring device, a hydraulic lifting device, a negative pressure suction device, a detachable mixing tank, and a discharging device. The detached mixing tank includes a bottomless Bucket 6 and sealing cover 8, the hydraulic lifting device is fixedly connected with sealing cover 8 through the upper pull rod 18, and the sealing cover 8 and the bottomless barrel 6 are movably connected through the cylinder 17 and the lower rod 20, and the cylinder 17 realizes the connection between the sealing cover 8 and the bottomless bucket. Closing and separation of the bottom barrel 6; the bottomless barrel 6 is a cylindrical barrel without a cover up and down, the pull rod 20 is used for piston movement in the cylinder 17, the inner wall of the bottomless barrel 6 is attached with a film, and the film covers the inner wall of the bottomless barrel 6. The surface is movably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com