Device and method for producing a material web

A technology of format and equipment, applied in the field of drying equipment, can solve the problems of expensive connection devices, long manufacturing and assembly time, etc., and achieve the effect of easy fixing and installation, and preventing slipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

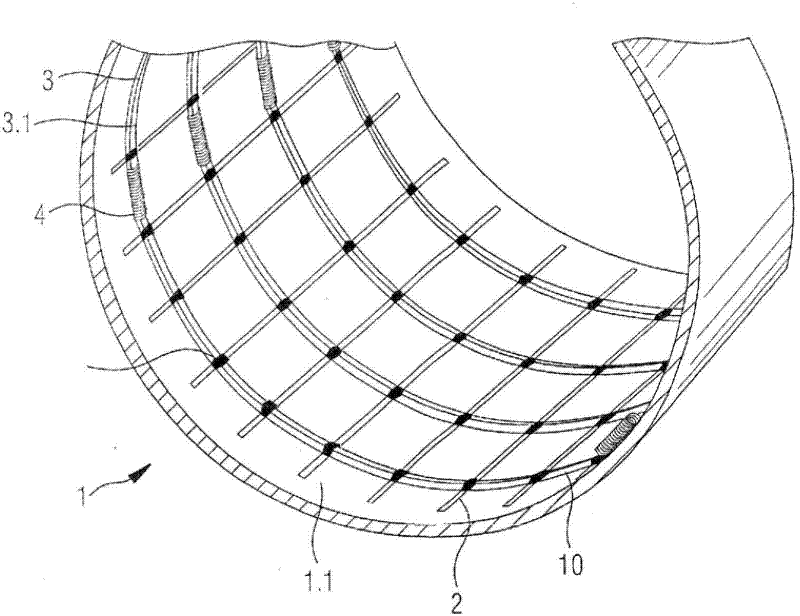

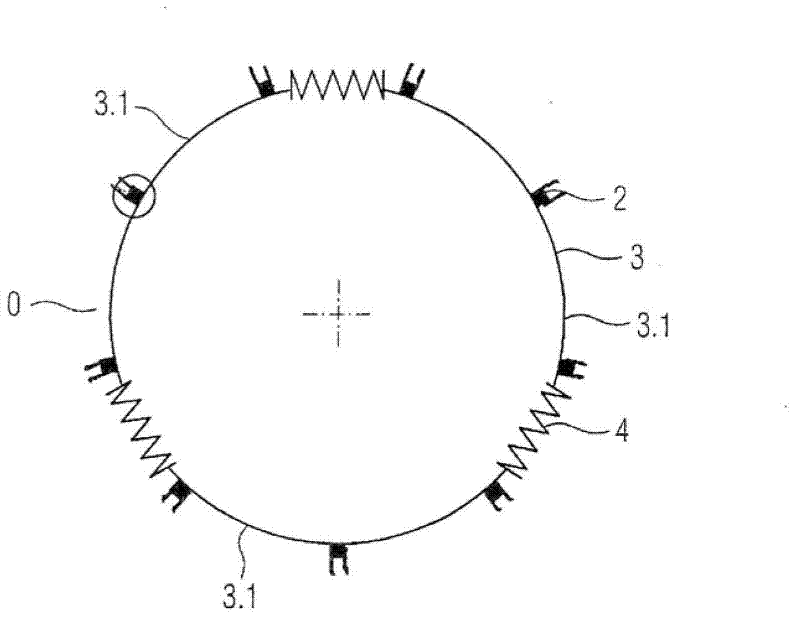

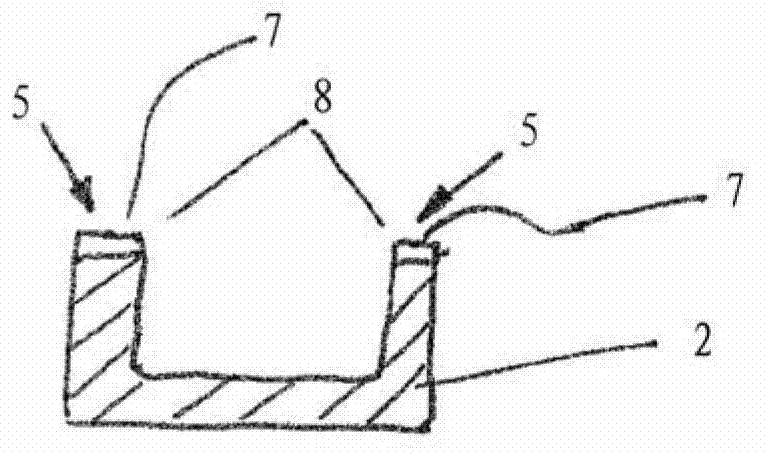

[0039] figure 1 A drying installation 1 according to the invention is shown which has a steam-heatable cylinder 1.1, in particular a drying cylinder 1.1 of a paper machine, which has a slat cage 10 installed in its interior. The interfering strips 2 are arranged axially, that is to say parallel to the longitudinal axis 1.1 of the drying drum, and are pressed against the shell surface 1.2 by means of four retaining rings 3 . The retaining ring 3 designed as an extruded element consists of several retaining ring segments 3.1. In order to generate a radial tension on the interfering strip 2 , the retaining ring segments are pressed against each other by tensioning elements, such as helical springs or cylindrical springs 4 . In this exemplary embodiment, there is a form-fit connection at each intersection point between the retaining ring segment 3 . 1 and the interfering strip 2 . The retaining rings 3 are arranged equidistantly. Expediently, they are arranged closer together i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com