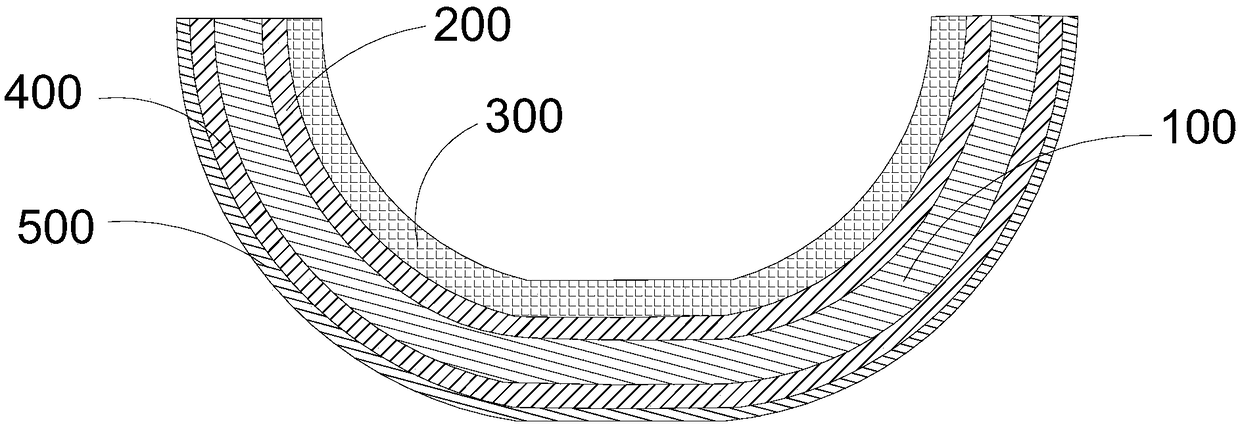

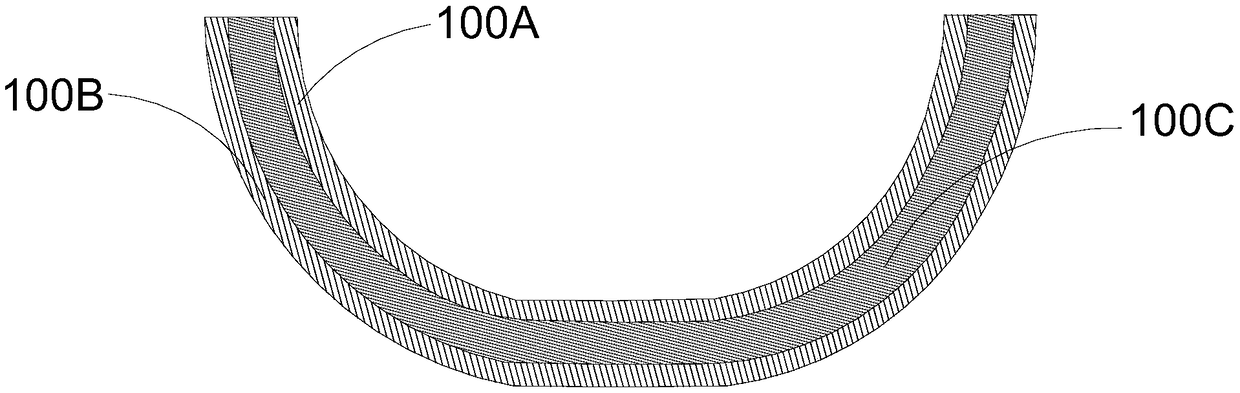

Stainless cooking utensil material, stainless cooking utensil and preparation method thereof

A technology for cooking utensils and stainless iron, which is applied to special materials for cooking utensils, metal material coating process, kitchen utensils, etc., can solve the problems of perforation of the pot body, formation of blisters, easy occurrence of blisters and perforations, etc., to reduce acid corrosion. and scratch wear, reduce the formation of trachoma and perforation, reduce the effect of trachoma and perforation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

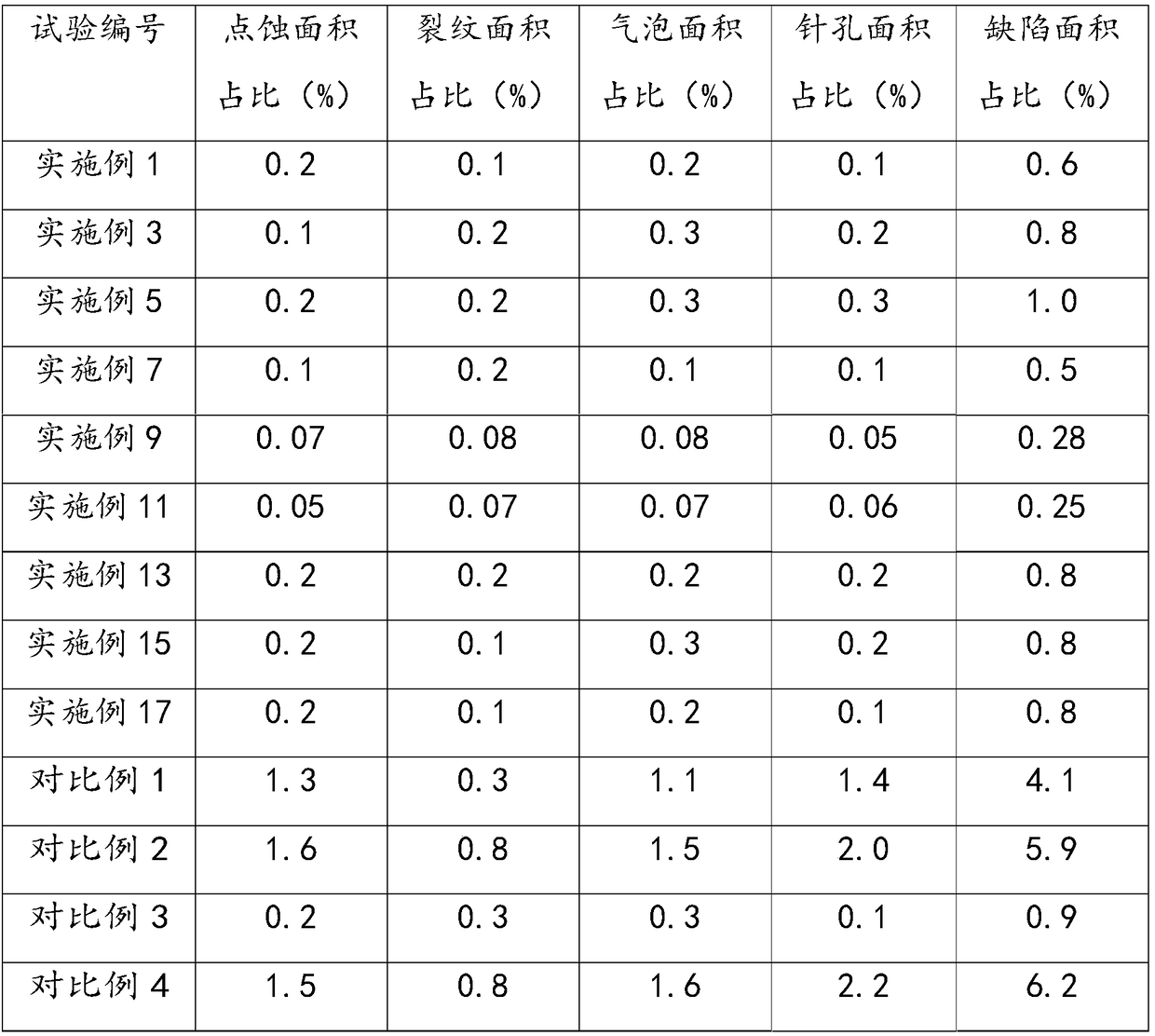

Examples

Embodiment 1

[0077] Sand blast the inner surface of the pot base made of steel to increase the roughness of the inner surface of the pot, Ra is 10um; use thermal spraying method to coat a layer of 200um titanium and / or The titanium alloy layer is thermal sprayed by electric arc thermal spraying; the surface of the titanium or titanium alloy layer obtained by thermal spraying is polished to reduce the surface roughness of the pot body.

[0078] Carry out nitriding treatment on the pot body, the nitriding method is carried out according to the gas nitriding method, the method is as follows: use the well-type resistance furnace to process, place the product pot mouth downward on the special nitriding fixture, hoist it into the well-type nitriding furnace, Cover the furnace cover; vacuumize the nitriding furnace to a vacuum degree of 0.02MPa, then feed ammonia gas to make the pressure in the furnace reach a positive pressure of 0.001MPa, and keep feeding ammonia gas continuously, and the gas ex...

Embodiment 2

[0082] Sand blast the inner surface of the pot base made of steel to increase the roughness of the inner surface of the pot, and the Ra is 8um; use a thermal spraying method to coat a layer of 160um titanium and / or The titanium alloy layer is thermal sprayed by electric arc thermal spraying; the surface of the titanium or titanium alloy layer obtained by thermal spraying is polished to reduce the surface roughness of the pot body.

[0083] Carry out nitriding treatment on the pot body, the nitriding method is carried out according to the gas nitriding method, the method is as follows: use the well-type resistance furnace to process, place the product pot mouth downward on the special nitriding fixture, hoist it into the well-type nitriding furnace, Cover the furnace cover; vacuumize the nitriding furnace to a vacuum degree of 0.03MPa, then feed ammonia gas to make the pressure in the furnace reach a positive pressure of 0.001MPa, and keep feeding ammonia gas continuously, and t...

Embodiment 3

[0087] The inner surface of the pot base made of cast iron is sandblasted to increase the roughness of the inner surface of the pot, and the Ra is 6um; the inner surface of the pot is coated with a layer of 120um titanium and / or titanium alloy layer, flame thermal spraying is used for thermal spraying; the surface of the titanium or titanium alloy layer obtained by thermal spraying is polished to reduce the surface roughness of the pot body.

[0088] Carry out nitriding treatment on the pot body, the nitriding method is carried out according to the gas nitriding method, the method is as follows: use the well-type resistance furnace to process, place the product pot mouth downward on the special nitriding fixture, hoist it into the well-type nitriding furnace, Cover the furnace cover; vacuumize the nitriding furnace to a vacuum degree of 0.04MPa, then feed ammonia gas to make the pressure in the furnace reach a positive pressure of 0.002MPa, and keep feeding ammonia gas contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com