Underground screw pump and construction method for penetrating underground screw pump

A construction method and the technology of screw pumps, which are applied in the direction of wellbore/well parts, pumps, pump components, etc., can solve the problems that screw pumps cannot pass through, and achieve the effects of reducing construction operation costs and preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, not to limit the protection scope of the present invention, and all improvements obtained by using the design idea of the present invention belong to the protection scope of the present invention.

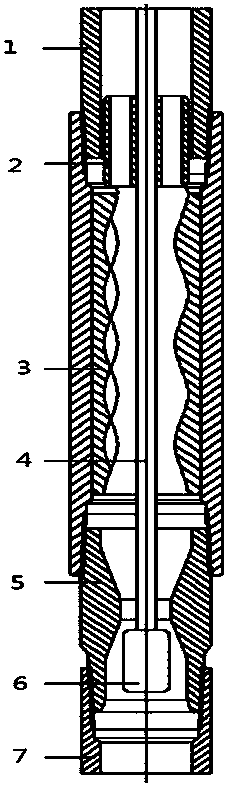

[0027] see figure 1 , a downhole screw pump includes a positioning pin 5, the positioning pin 5 is connected to the lower end of the stator 3, and the positioning pin 5 is provided with a central hole through which construction instruments or tools 6 can pass. The stator 3 in the screw pump has a single-layer structure or a double-layer structure. The construction instrument or tool 6 includes a gamma meter, a magnetic locator, a pressure gauge, a weighted rod and a sliding sleeve opening tool. After the construction instrument or tool 6 passes through the screw pump, the depth of the pipe string under the pump can be checked by electrical measurement , Measuring the dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com