Method for directly producing ring parts by centrifugal casting and cold rolling

A technology of centrifugal casting and ring parts, which is applied in the field of direct production of ring parts by centrifugal casting and cold rolling, can solve the problems of unfavorable energy saving and emission reduction, low production efficiency, and high energy consumption, and achieve material saving, production efficiency improvement, The effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

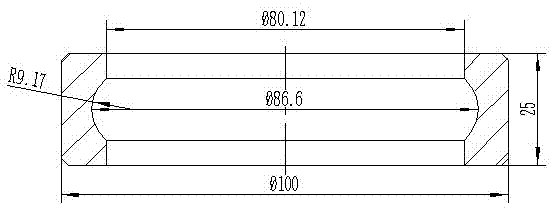

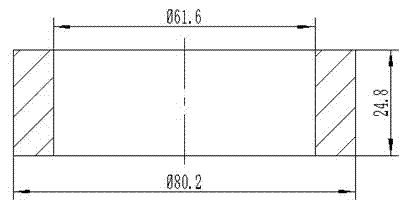

[0018] Production as figure 1 The bearing ring shown has an outer diameter of Φ100mm, an inner diameter of Φ80.12mm, and a height of 25mm. The material used is 42CrMo steel. The size of the cast tube is Φ80.2mm with an outer diameter of Φ61.6mm and a length of 3m.

[0019] The process steps are:

[0020] ①Melting the alloy in an intermediate frequency furnace at a temperature of 1700℃;

[0021] ②Use the LF ladle refining furnace to refine the molten steel outside the furnace, the refining temperature is 1690℃, and the bottom blowing argon gas is stirred for deoxidation and desulfurization;

[0022] ③Pour the refined 1555℃ molten steel into a horizontal centrifuge and cast it into a tube, the speed is 20r / s, the pouring time is 5s, and the tube mold is drawn when it is cooled to 500℃. The size of the casting tube is Φ80.2mm. The inner diameter is Φ61.6mm and the length is 3m;

[0023] ④The cast pipe is automatically sawed and cut by a steel pipe blanking machine, and sawed into a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com