Upper-air formwork support and outer scaffold shared cantilever structure

An external scaffolding and cantilever technology, which is applied to the scaffolding supported by the building structure, the accessories of the scaffolding, the formwork/template/work frame, etc. problems, to achieve the effect of improving the overall force performance, saving manpower, material resources and financial resources, and high carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

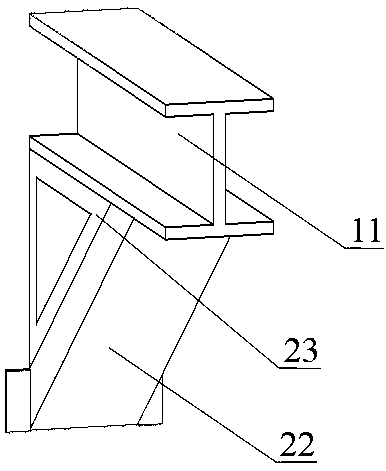

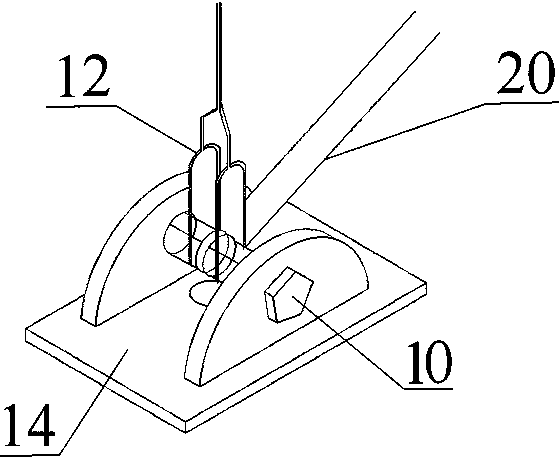

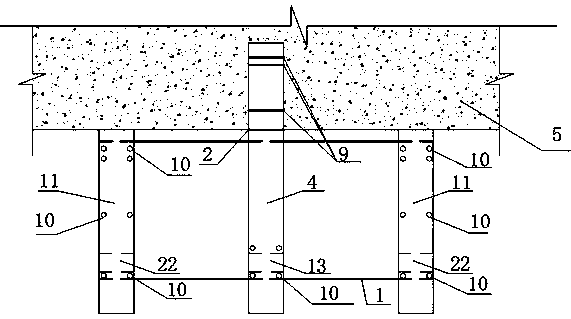

[0047] Such as Figure 1~Figure 11 As shown, the structure includes a U-shaped pull ring, a vertical rectangular steel plate, a horizontal rectangular steel plate, a rectangular truss brace, a rectangular hollow brace, a triangular steel plate, a bent anchor, a wall seat, a shorter steel wire rope, a longer steel wire rope, Vertical pressure bar, the first cantilevered steel beam, the second cantilevered steel beam, wooden wedges, formwork brackets, and external scaffolding. Both the first cantilevered steel beam and the second cantilevered steel beam are arranged on the n-floor floor. Horizontal rectangular steel plate connections. The vertical rectangular steel plate is pre-welded with the U-shaped pull ring. The place where the top right angle side of the triangular steel plate contacts the vertical rectangular steel plate is fully welded. The place where the other right angle side of the triangular steel plate contacts the floor is fixed with two bolts. The triangular ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com