Quadruplet rotating disk movable steaming bucket

A quadruple and retort technology, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of long labor time, irritable operation of workers, and affecting the quality of fermentation, so as to improve the quality of fermentation and original wine, and avoid excessive fermentation. Sticky, cost-effective investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

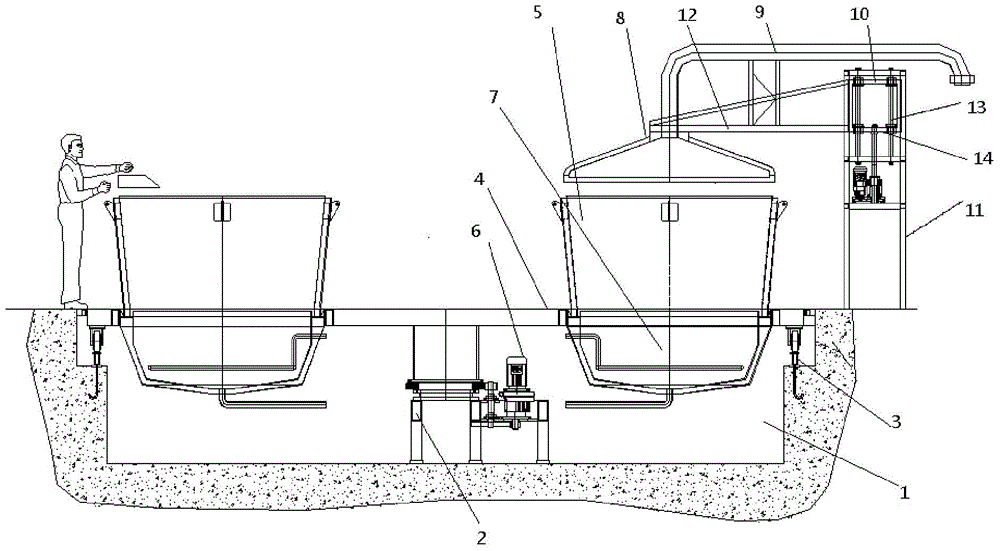

[0010] Referring to the accompanying drawings, the quadruple turntable live retort bucket includes a sinking tank 1 opened on the ground, a step surface is opened at the notch of the sinking tank 1, and a circular support ground rail 3 is provided on the step surface, and the center of the sinking tank 1 A rotary support platform 2 is provided at the center, and a turntable body 4 is installed on the rotary support platform 2. A retort cylinder 5 is installed on the turntable body 4. A driving mechanism 6 is installed on the side of the rotary support platform 2. The driving mechanism 6 and the turntable body 4 are connected through gears. Transmission connection, a bottom pot 7 is installed in the retort tube 5, a retort cover 8 is installed on the retort tube 5, a steam pipe 9 is connected to the retort cover 8, a cover lifting machine 10 is arranged on the outside of the retort tube 5, and the cover lifting machine 10 includes Frame 11 and pull rod 12 are arranged, and guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com