Microbial inoculum and application thereof in improvement of facility agriculture

A microbial inoculum, a technology for facility agriculture, applied in the direction of microorganism-based methods, microorganisms, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

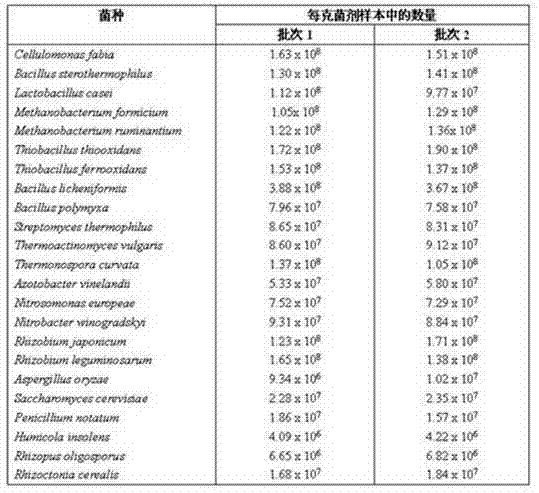

[0048] The production of embodiment 1 microbial bacterial agent

[0049] The present embodiment uses the following strains to prepare microbial inoculum: (1) Cellulomonas faeci ( Cellulomonas fabia ), (2) Bacillus stearothermophilus ( Bacillus sterothermophilus ), (3) Lactobacillus casei ( Lactobacillus casei ), (4) Methanobacter ants ( Methanobacterium formicium ), (5) Methanobacter ruminantum ( Methanobacterium ruminantium ), (6) Thiobacillus thiooxidans ( Thiobacillus thiooxidans), (7) Thiobacillus ferrooxidans ( Thiobacillus ferrooxidans ), (8) Bacillus licheniformis ( Bacillus licheniformis ), (9) Bacillus polymyxa ( Bacillus polymyxa ), (10) Streptomyces thermophilus ( Streptomyces thermophilus ), (11) common high temperature actinomycetes ( Thermoactinomyces vulgaris ), (12) Thermomonospora curved ( Thermonospora curvata ), (13) brown nitrogen-fixing bacteria ( Azotobacter vinelandii ), (14) Nitrosomonas europeanum ( Nitrosomonas europeae ), (...

Embodiment 2

[0052] Example 2 Production of Organic Fertilizer

[0053] Take cow dung with a water content of 65% (weight ratio) (if the water content is insufficient, you can add water) and crushed rice bran with particles smaller than 5mm, mix them evenly at a mass ratio of 85:15, and make the mixed cow dung and rice bran There is no agglomeration above 40mm.

[0054] Then, the mixture of 1 ton of above-mentioned cow dung and rice bran is mixed with the microbial inoculant produced in 1kg of Example 1, and heaped into the fermenter to form a compost heap. During the compost heap placement period, along with the fermentation process, the compost heap can naturally heat up. This fermentation heating process usually takes 2-3 days, and the compost heap can be turned 1-2 times during this period. Then, when the temperature of the compost heap rises to 65°C, turn on the turner to turn the compost heap to dissipate the heat generated by fermentation to ensure that the temperature does not e...

Embodiment 3

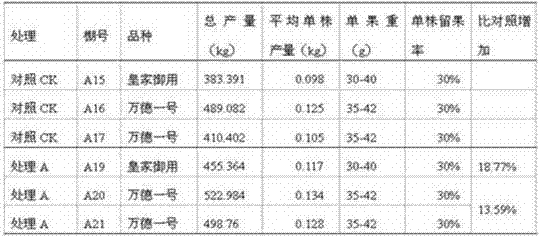

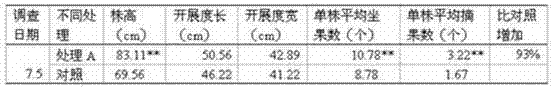

[0056] Example 3 Effects of Organic Fertilizers on Fruit Growth and Yield

[0057] This embodiment describes that the inventor entrusted Beijing Wandeyuan Agricultural Science and Technology Development Co., Ltd. to carry out in Beijing Changping District Facility Strawberry Park (Xiaotangshan Wande Strawberry Garden) from August 1, 2011 to March 1, 2012 Effect test of strawberry planting application.

[0058] 1. Test materials and design

[0059] 1.1 Test material

[0060] Bio-organic fertilizer: the organic fertilizer produced by the same method as in Example 2

[0061] Strawberry Varieties: Imperial Use, Wande No. 1 (Dianxue).

[0062] 1.2 Experimental design

[0063] The experiment has two treatments:

[0064] ① Greenhouses numbered A15, A16, and A17 were set as the control, numbered CK; the base fertilizer of the control and test sheds used 2.5 tons of puffed chicken manure per mu as the base fertilizer, and the control shed applied 100kg / mu of Stanley compound fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com