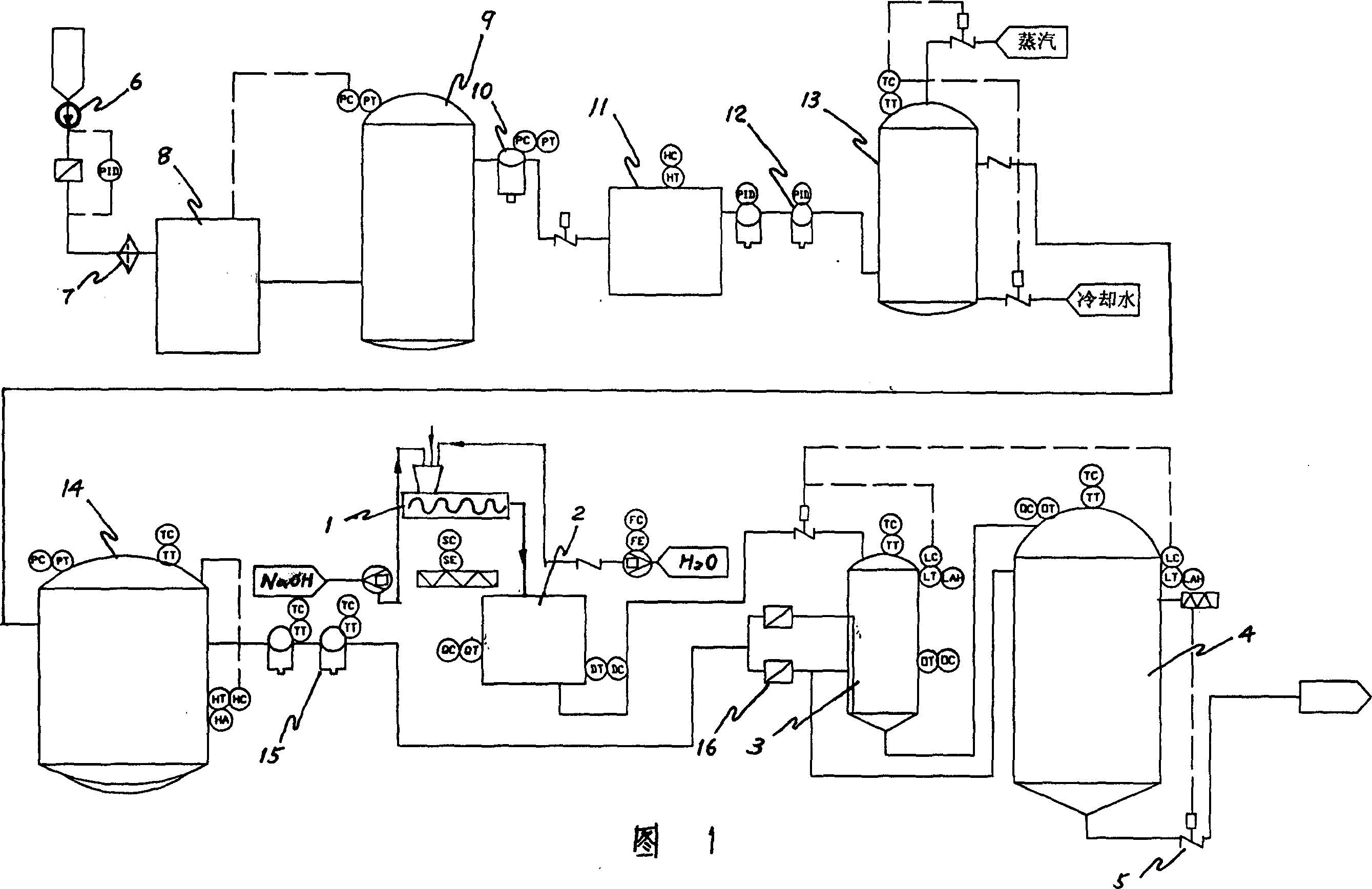

Liquid fermentation process of streptomyces flavus and its production equipment

A liquid fermentation technology of Streptomyces flavinus, applied in the direction of bacteria, botanical equipment and methods, biocides, etc., can solve the problems of no production process and production equipment, small and insignificant number of Streptomyces flavinus, and avoid expansion The effect of loss, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1. A liquid fermentation process of Streptomyces flavinus. It includes the following steps:

[0036] (1) Mixing of protein and carbohydrate raw and auxiliary materials: send protein and carbohydrate raw and auxiliary materials, water and sodium hydroxide into the material mixing tank, and mix while sending until uniformly mixed, so that the solid concentration of raw and auxiliary materials is 30 %, the pH value of raw and auxiliary materials is 9.0;

[0037] (2) Disinfection of empty and solid seed cans: first sterilize the empty cans, then put raw and auxiliary materials into the sterilized solid cans, and sterilize with superheated steam at a temperature of 115°C for 40 minutes;

[0038] (3) Inoculation: after the solid tank is sterilized, cool the raw and auxiliary materials with pipeline cooling water, and when it reaches 30°C, inoculate the seeds of Streptomyces flavinus by 1% of the mass ratio of the raw and auxiliary materials;

[0039] (4) Seed tan...

Embodiment 2

[0046] Embodiment 2. A liquid fermentation process of Streptomyces flavinus. It includes the following steps:

[0047] (1) Mixing of protein and carbohydrate raw and auxiliary materials: send protein and carbohydrate raw and auxiliary materials, water and sodium hydroxide into the material mixing tank, and mix while sending until uniformly mixed, so that the solid concentration of raw and auxiliary materials is 33 %, the PH value of raw and auxiliary materials is 8.7;

[0048] (2) Disinfection of empty and solid seed cans: first sterilize the empty cans, then put raw and auxiliary materials into the sterilized solid cans, and sterilize with superheated steam at a temperature of 126°C for 35 minutes;

[0049] (3) Inoculation: after the solid tank is sterilized, cool the material with pipeline cooling water, and when it reaches 26°C, inoculate the seeds of Streptomyces flavinus by 1.7% of the mass ratio of raw and auxiliary materials;

[0050] (4) Fermentation in seed tanks: t...

Embodiment 3

[0057] Embodiment 3. A liquid fermentation process of Streptomyces flavinus. It includes the following steps:

[0058] (1) Mixing of protein and carbohydrate raw and auxiliary materials: send protein and carbohydrate raw and auxiliary materials, water and sodium hydroxide into the material mixing tank, and mix them while sending until they are evenly mixed, so that the solid concentration of raw and auxiliary materials is 35 %, the PH value of raw and auxiliary materials is 8.5;

[0059] (2) Sterilization of empty and solid seed cans: first sterilize the empty cans, then fill the raw and auxiliary materials into the sterilized solid cans, and sterilize with superheated steam at a temperature of 120°C for 30 minutes;

[0060] (3) Inoculation: after the solid tank is sterilized, cool the material with pipeline cooling water, and when it reaches 28°C, inoculate the seeds of Streptomyces flavinus by 2% of the mass ratio of raw and auxiliary materials;

[0061] (4) Seed tank ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com